Fireproof medium-voltage multi-core cable

A multi-core cable, medium-voltage technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of insulated wire core insulation marks damage, and achieve the effect of preventing marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

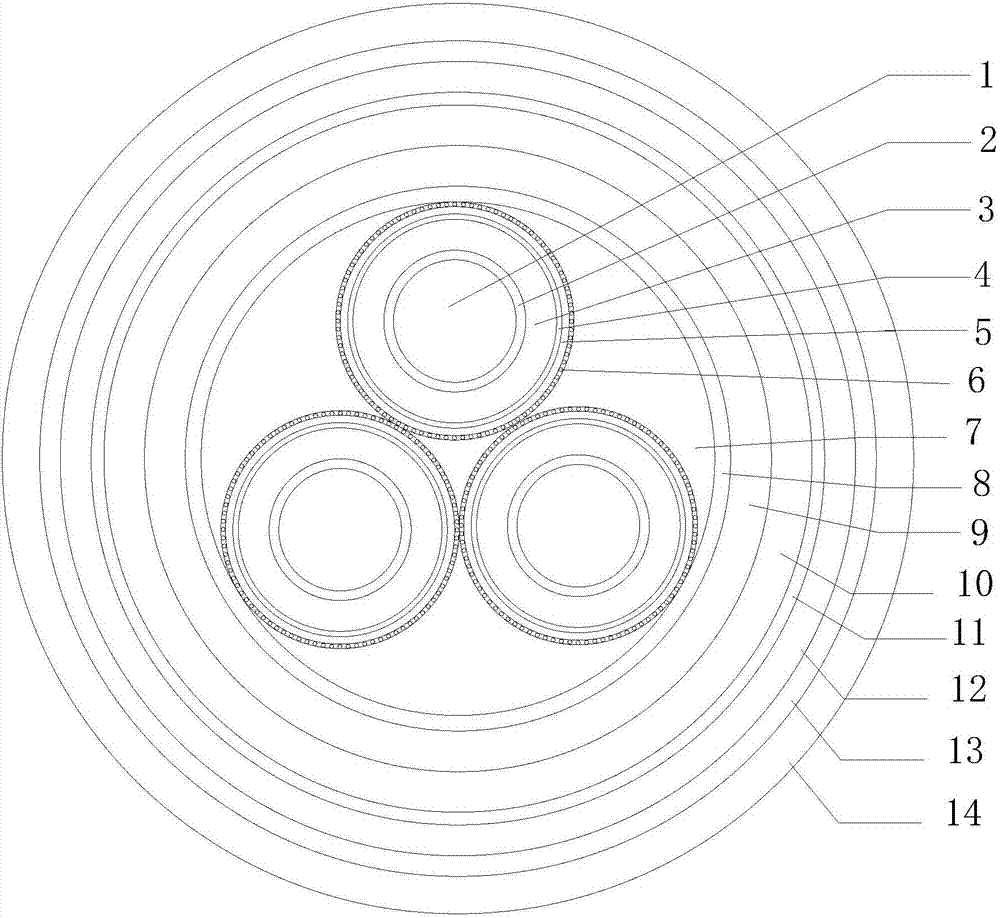

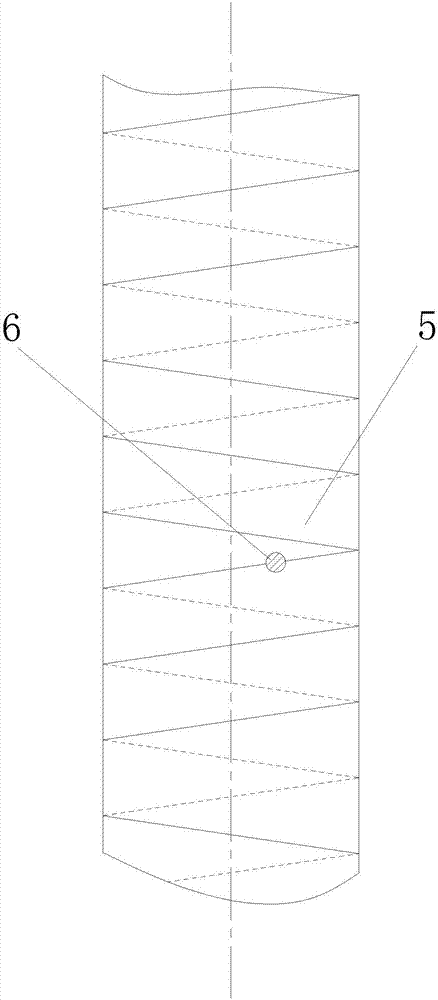

[0017] Such as figure 1 , figure 2 As shown, the present invention includes three cable cores, the flame-retardant glass fiber wrapping tape 8 that wraps each cable core therein, and the first layer of ceramicized fire-proof and refractory polyolefin sheathing that is wrapped outside the flame-retardant glass fiber wrapping tape 8. Sleeve 9; each cable core includes a conductor 1 and an inner screen 2, an insulating layer 3 and an outer screen 4 that are sequentially coated on the conductor 1 from the inside to the outside. The outer screen 4 is covered with a high-temperature-resistant buffer semi-conductive tape 5, and the high-temperature-resistant buffer semi-conductive tape 5 is wound with an SZ-shaped twisted copper wire 6; in addition, the first layer of ceramic fireproof and refractory polyole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com