Synchronous ejector pin mechanism of injection mold

A technology of injection molds and thimbles, which is applied in the field of synchronous thimble mechanisms, can solve the problems of plastic products with marks, damage, and uneven force on plastic products, and achieve the effect of avoiding marks or damage and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

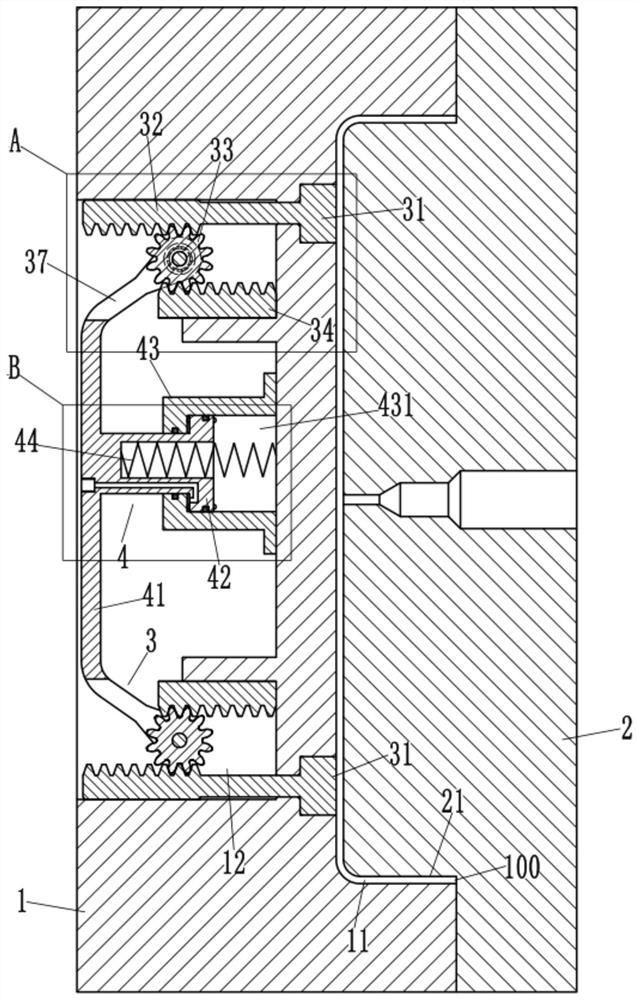

[0019] Examples such as Figure 1-3 As shown, a synchronous thimble mechanism of an injection mold includes a fixed mold 1 and a movable mold 2 arranged on the left and right. The convex module 21, the plastic product is molded in the cavity 100 formed by the convex module 21 and the concave mold cavity 11;

[0020] A drive cavity 12, a plurality of thimble holes 13 connecting the drive cavity 12 and the die cavity 11 are formed in the fixed mold 1;

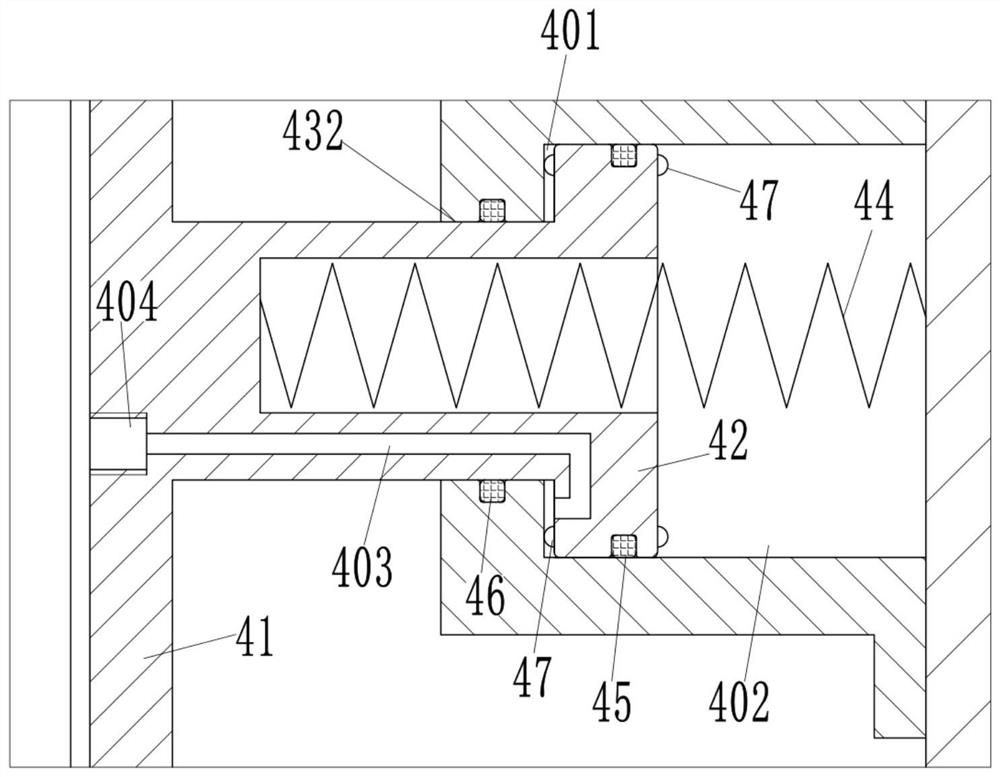

[0021] The drive cavity 12 is provided with a plurality of thimble mechanisms 3 and a drive mechanism 4 that drives the plurality of thimble mechanisms 3 to work simultaneously;

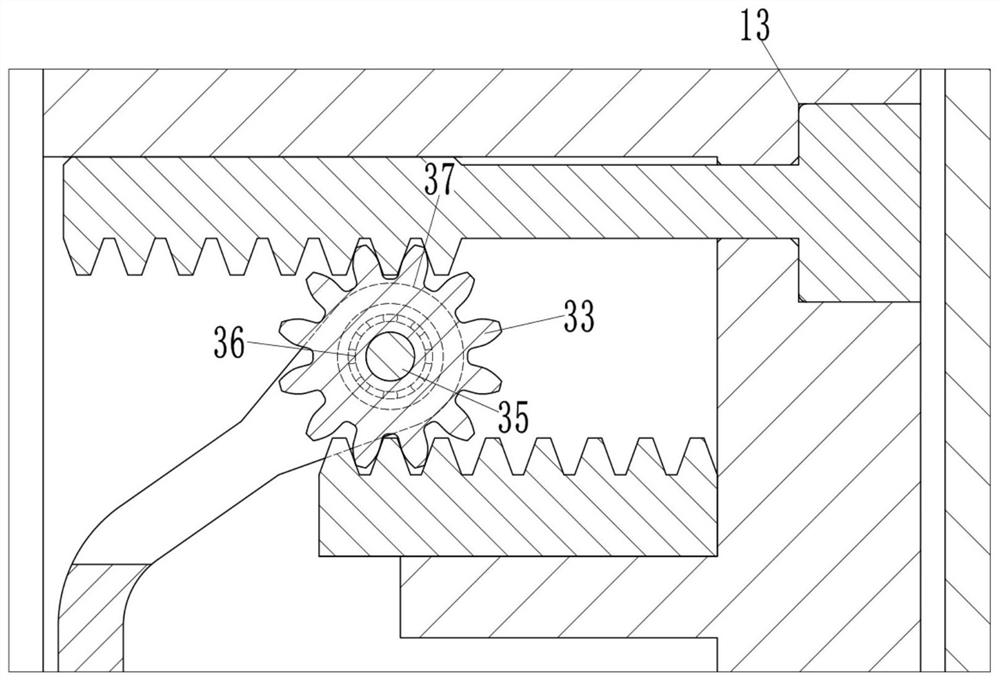

[0022] The thimble mechanism 3 includes a thimble 31 inserted in the thimble hole 13, the left end of the thimble 31 is fixedly connected with a movable rack 32, the movable rack 32 is meshed with a gear 33, the gear 33 is meshed with a fixed rack 34, and the fixed tooth The bar 34 is fixedly connected with the driving cavity 12; the gear 33 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com