Warehouse bottom bulk loader

A bulk machine and hoisting mechanism technology, applied in the field of machinery, can solve the problems of inconvenient operation, easy dust pollution, low degree of automation, etc., and achieve the effects of easy operation, stable and reliable working performance, and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

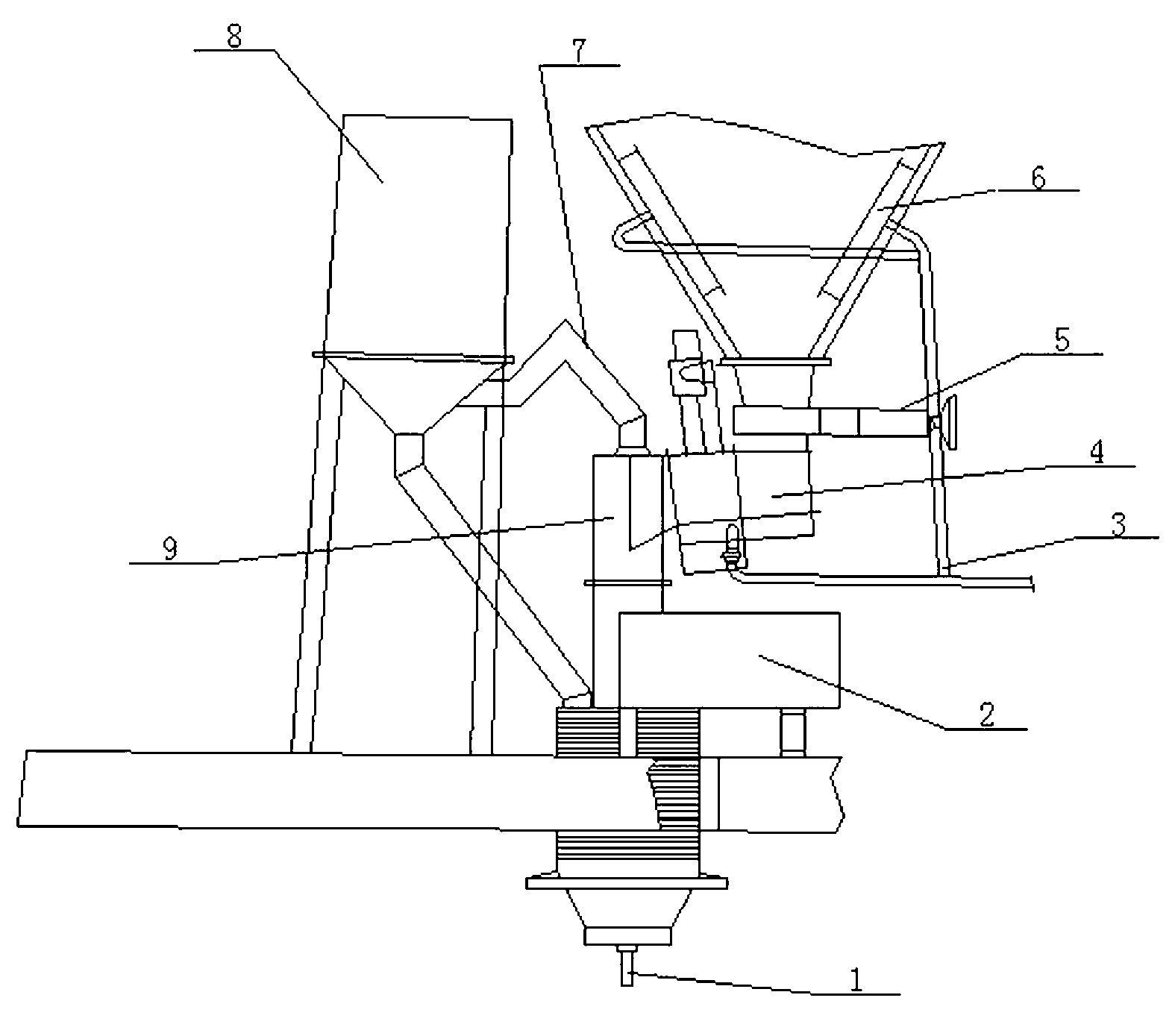

[0008] refer to figure 1 , the specific implementation method adopts the following technical solutions: a warehouse bottom bulk machine, which includes a material level probe 1, a winch mechanism assembly 2, a pipeline system 3, a curved groove 4, a spiral gate 5 and a fluidization device 6, the The top of the material level probe 1 is connected with a hoisting mechanism assembly 2, the fluidization device 6 is arranged above the hoisting mechanism assembly 2, the bottom of the fluidization device 6 is provided with a spiral gate 5, and the spiral gate 5 A curved groove 4 is connected, and a pipeline system 3 is connected to one side of the fluidization device 6. The curved groove 4 is connected to a discharge chute 9, and the discharge chute 9 is connected to a dust collector through a dust collection pipe 7. 8.

[0009] The material level probe 1 is a retractable material level probe, which effectively improves the automation of loading, avoids excessive discharge or insuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com