Garlic sectioning and grading mechanized device and control method thereof

A grading device, a technology of dividing the petals, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc. It can avoid problems such as poor performance and cumbersome transportation process, and achieve the effect of avoiding insufficient feeding amount, strong integrity, and improving the efficiency of valve splitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

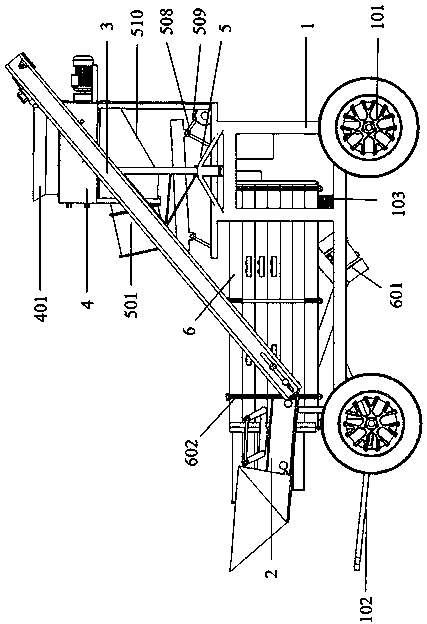

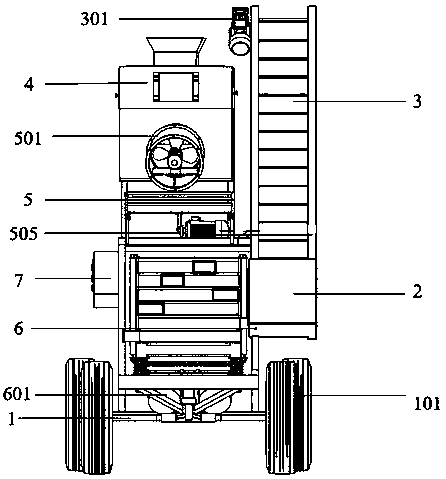

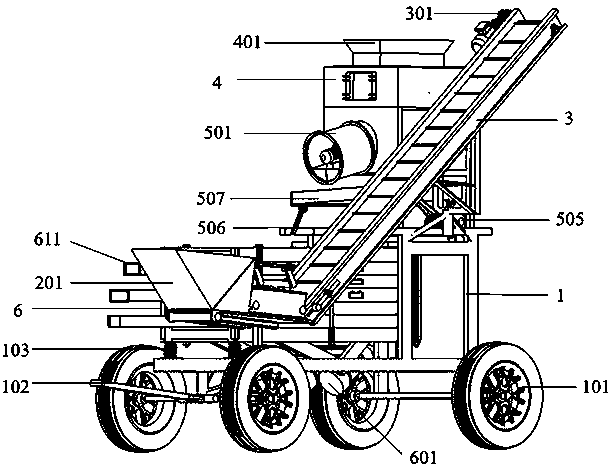

[0042] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0043] Such as Figure 1~3 A mechanized device for garlic splitting and grading is shown, including a chassis 1, and an initial splitting rubbing device 2, a conveying device 3, a splitting device 4, a cleaning device 5, a grading device 6, and a set of intelligent control devices installed on the chassis. device7. Chassis 1 is a wheeled chassis equipped with walking wheels 101 and walking drive, and the wheeled chassis is the support and installation platform of the whole machine; the first splitting and kneading device 2 is located at the leftmost front end of the whole machine, and is used to collect the dumped garlic. And carry out the preliminary garlic splitting; the conveying device 3 is installed on the left front side of the whole machine, the rear side of the first splitting rubbing device 2, the feeding end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com