Automatic auxiliary feeding system

An automatic feeding and auxiliary technology, applied in the field of textile printing and dyeing, can solve the problems of inconvenient archiving of weighing data, difficulty in equipment manufacturing and maintenance, and low efficiency, so as to avoid taking too much or too little material and improve the accuracy of extraction , The effect of reducing the cost of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

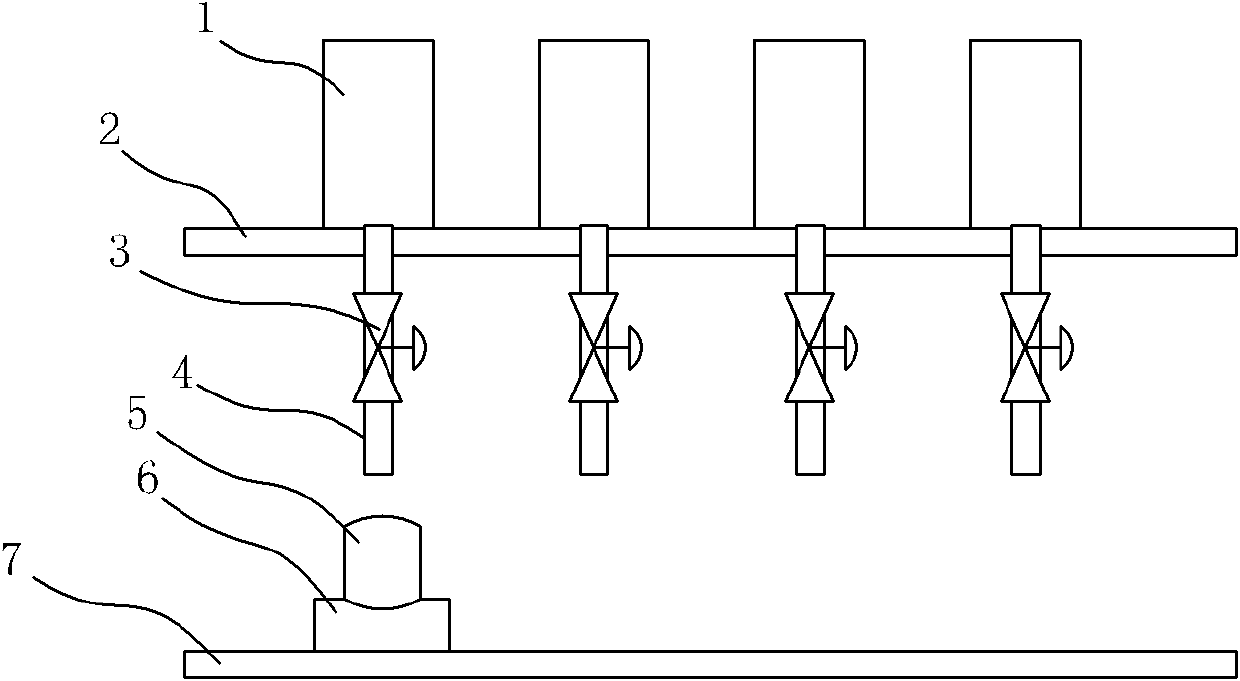

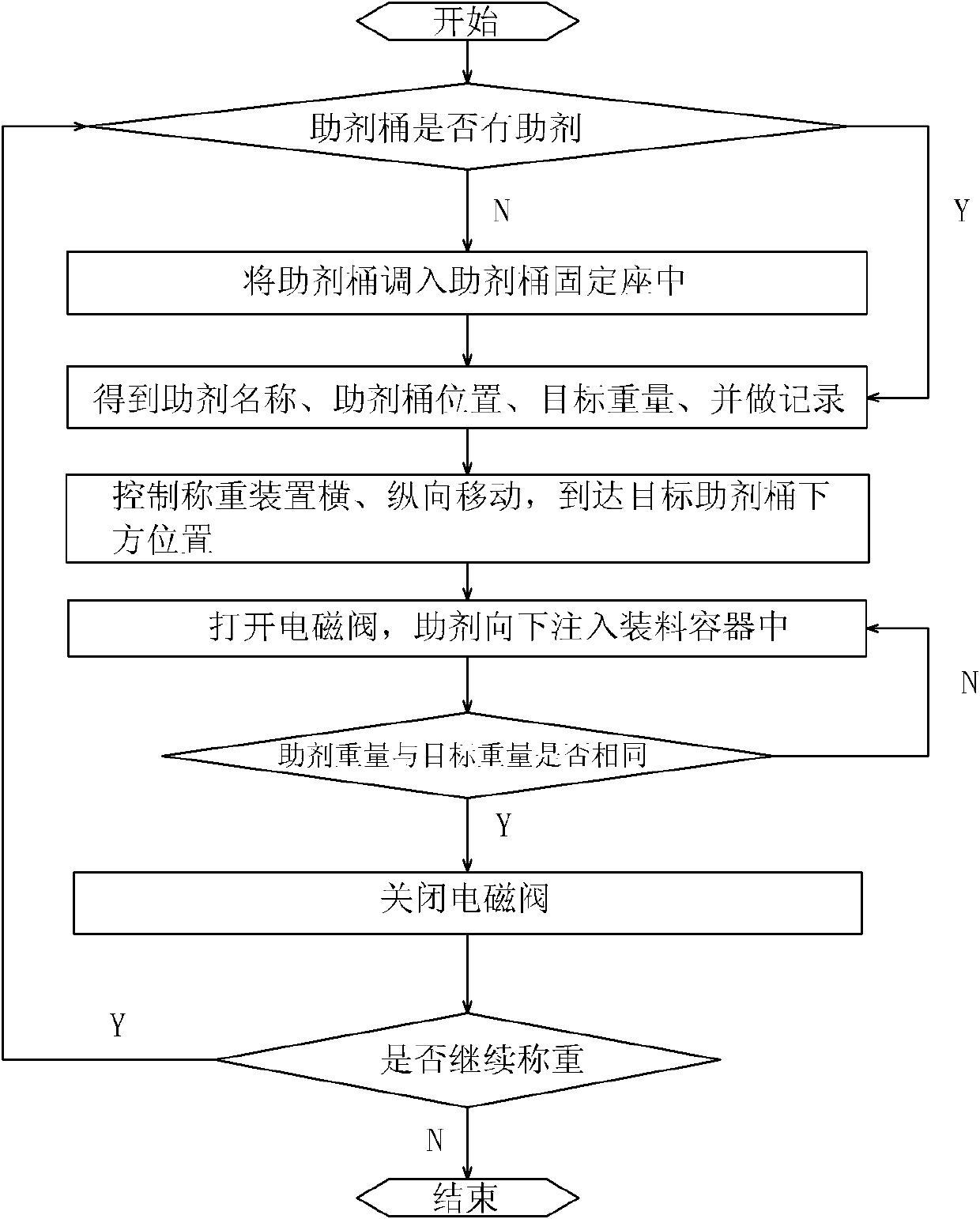

[0021] refer to figure 1 , figure 2 and image 3 As shown, an automatic additive feeding system includes a bracket, several additive barrels 1, a weighing device and a driving device.

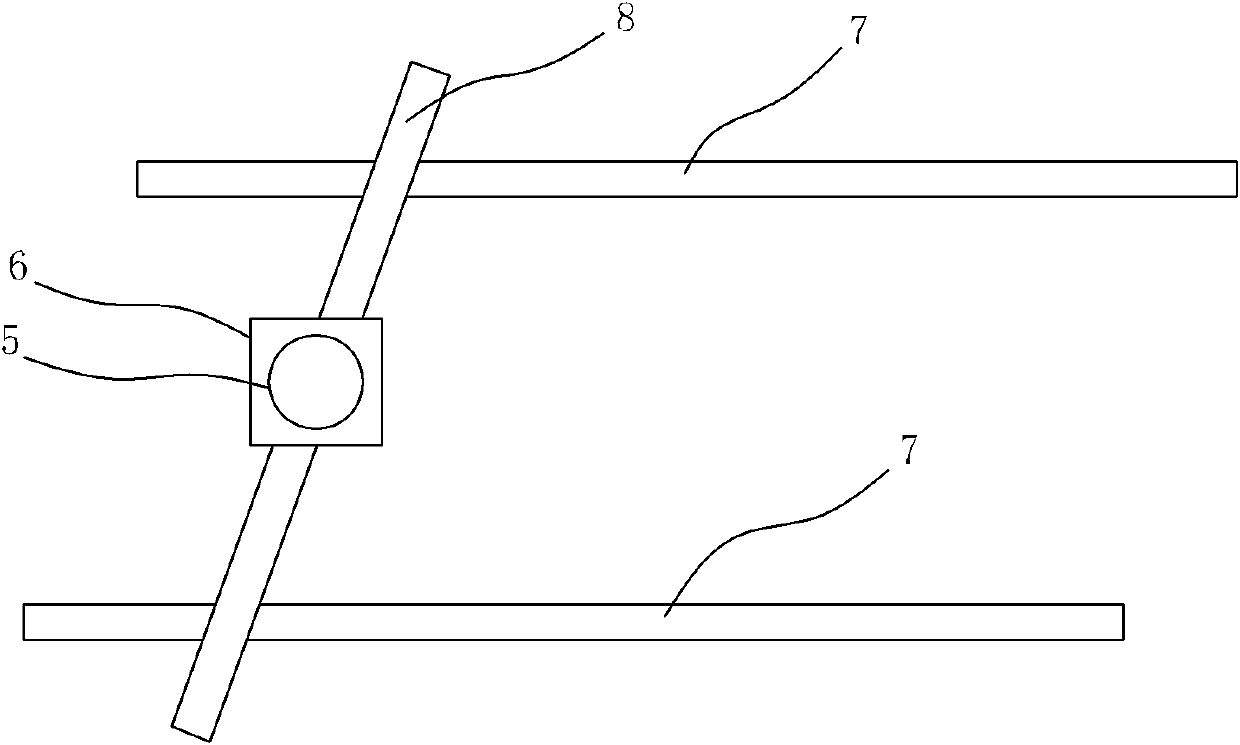

[0022] The bracket is used to support the auxiliary bucket 1 at a high position, on which there are fixed seats 2 for placing the auxiliary bucket 1; There is a discharge pipe 4 communicating with its interior, and a solenoid valve 3 for controlling the on / off of the discharge pipe 4 is arranged on the discharge pipe 4; the weighing device consists of an electronic scale 6 and a charging device arranged on the electronic scale 6 The container is composed of 5, and the electronic scale 6 is movably arranged on the beam 8 of the driving device; the driving device is used to drive the electronic scale 6 to move between the bottoms of the auxiliary buckets 1. Specifically, the driving device includes two guide rails 7 extending horizontally and horizontally. , a movable crossbeam 8 that is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com