Automatic feedback supplementing method for high-density culture of lactic acid bacteria

A technology for high-density culture and lactic acid bacteria, applied in the field of automatic feedback feeding of high-density cultured lactic acid bacteria, can solve the problems of inapplicability of exponential flow addition, and achieve the effects of ensuring stability, eliminating substrate inhibition, and reducing inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

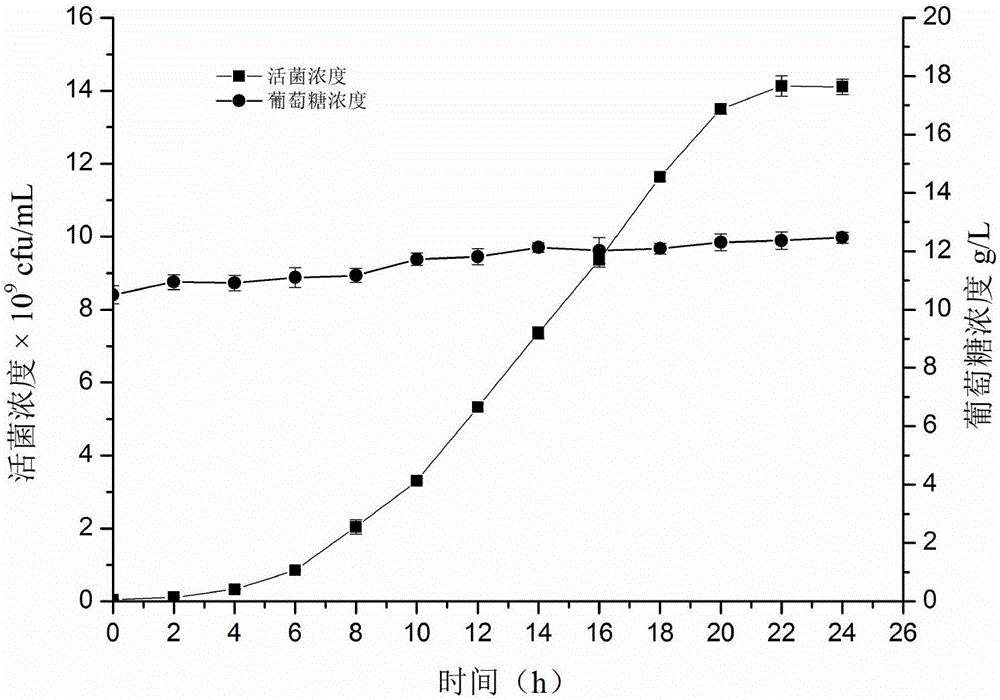

[0035] Embodiment 1 automatic feedback feeding high-density culture Lactobacillus casei

[0036] (1) Preparation of seed solution

[0037] Draw 200μL of Lactobacillus casei from the glycerol storage tube into 10mL MRS liquid medium, incubate at 42°C for 18 hours for activation, and then transfer it to 100mL MRS liquid medium with a 5% (v / v) inoculation amount for the second time After activation, cultivate at 42°C for 12 hours to obtain the seed solution.

[0038] (2) Preparation before vaccination and vaccination process

[0039] Prepare 600 mL of MRS liquid medium with half the concentration of carbon source and nitrogen source and pour it into a 1L fermenter. After the fermenter body is sterilized at 121 °C, it is cooled to 42 °C in a water bath and the temperature is kept constant. When starting the inoculation, above the alcohol flame circle, pour the seed solution into the fermenter with an inoculation amount of 5% (v / v), stir at a speed of 150-200 r / min, and cultivate...

Embodiment 2

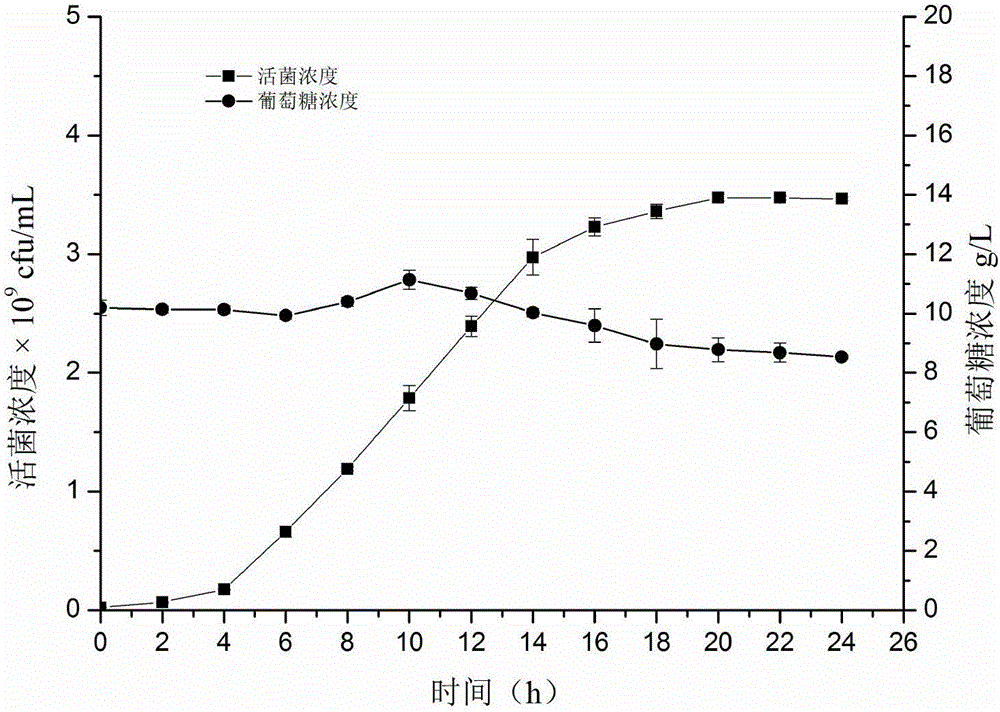

[0048] Example 2 Automatic Feedback Feeding High Density Cultivation of Bifidobacterium adolescentis

[0049] (1) Preparation of seed solution

[0050] Draw 200 μL of Bifidobacterium adolescentis from the glycerol storage tube into 10mL MRS liquid medium (adding 1g / L cysteine hydrochloride), put it into the anaerobic workstation for 24 hours at 37°C, and then add 5% (v The inoculum amount of / v) was transferred to 100 mL of liquid medium for secondary activation, and the seed liquid was obtained by anaerobic cultivation at a constant temperature of 37° C. for 15 hours.

[0051] (2) Preparation before vaccination and vaccination process

[0052] Prepare 600 mL of MRS liquid medium (adding 1 g / L cysteine hydrochloride) with half the concentration of carbon source and nitrogen source and pour it into a 1L fermenter. °C and keep the temperature constant. When starting the inoculation, pour the seed liquid into the fermenter with an inoculum amount of 5% (v / v) above the alco...

Embodiment 3

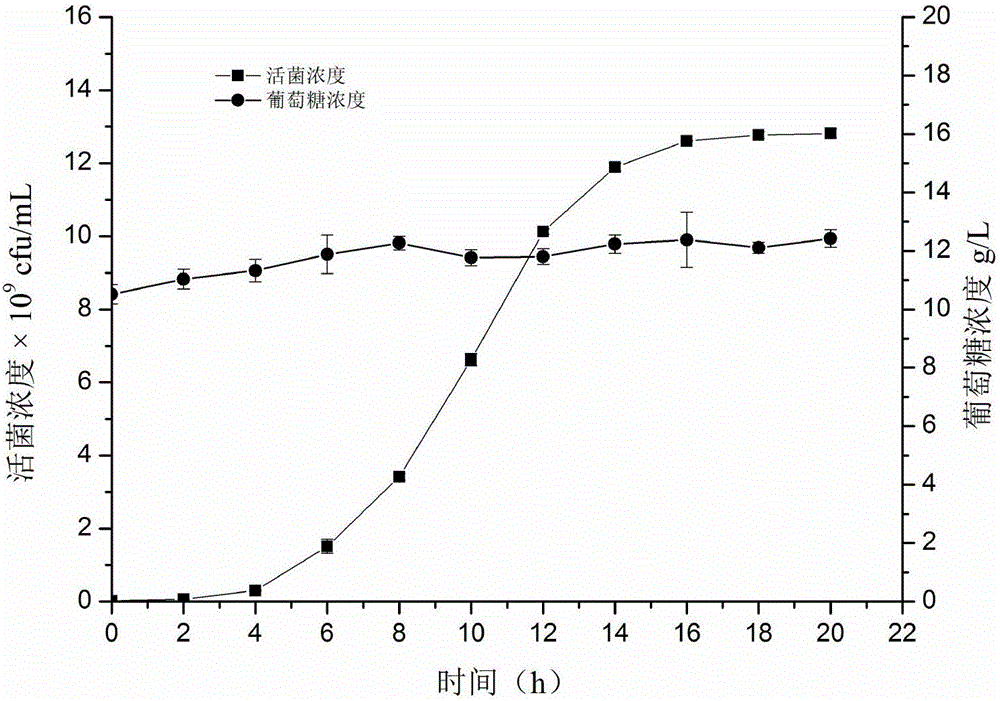

[0061] Example 3 Automatic Feedback Feeding High Density Cultivation of Plant Bacteria

[0062] The automatic feedback feeding culture of Lactobacillus plantarum, Lactobacillus bulgaricus, Lactobacillus helveticus, Lactobacillus rhamnosus, Lactobacillus acidophilus and other homofermentative lactobacilli is the same as in Example 1, and the culture temperature is the optimum growth temperature of each strain. like figure 2 As shown, Lactobacillus plantarum reached a final viable concentration of 1.3±0.1×10 after 16 hours of culture 10 cfu / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com