Method for preparing natural perfume gamma-decanolide by fermentation

A technology of natural spices and decanolactone, applied in the field of bioengineering, can solve the problems of poor substrate dispersion, high toxicity of product bacteria, low yield of γ-decalactone, etc., to reduce inhibition and enhance emulsification effect , the effect of shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

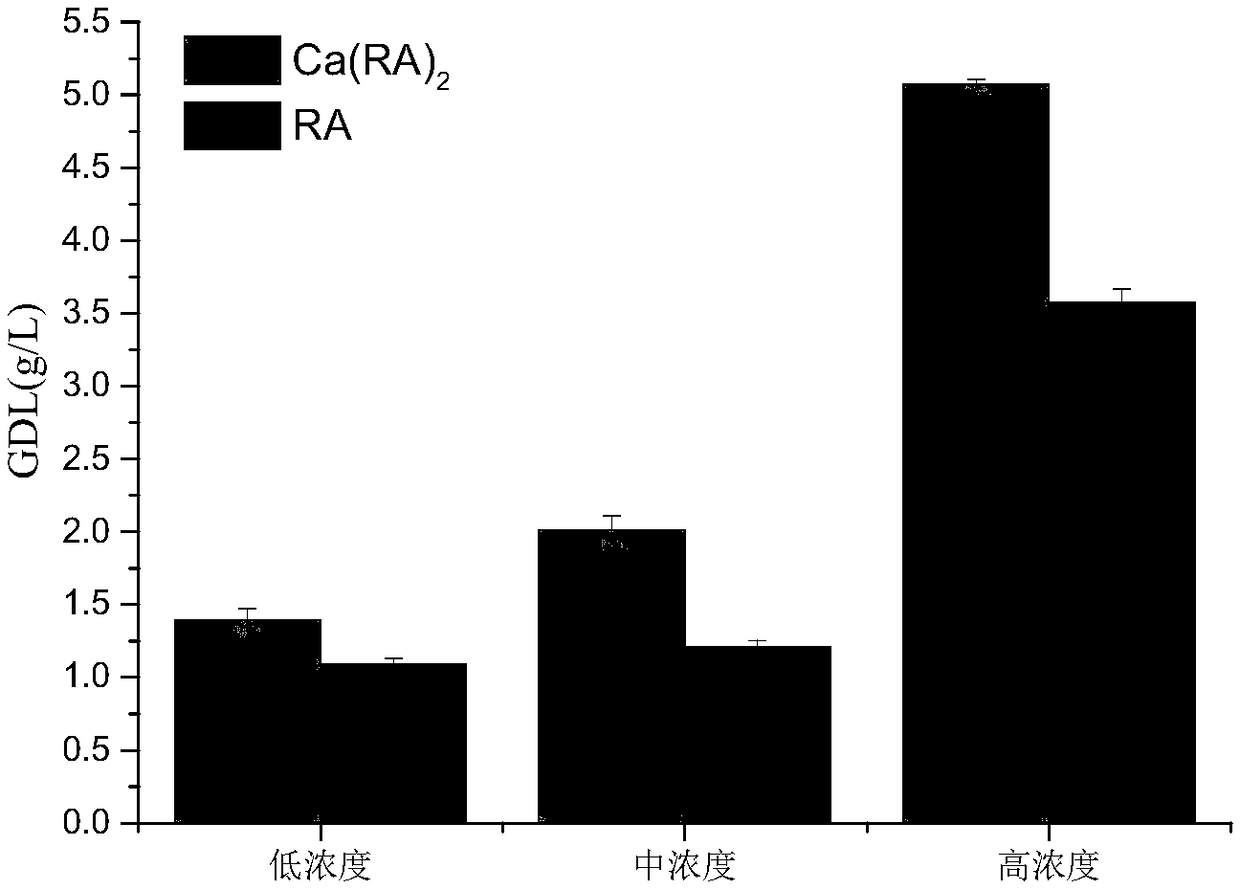

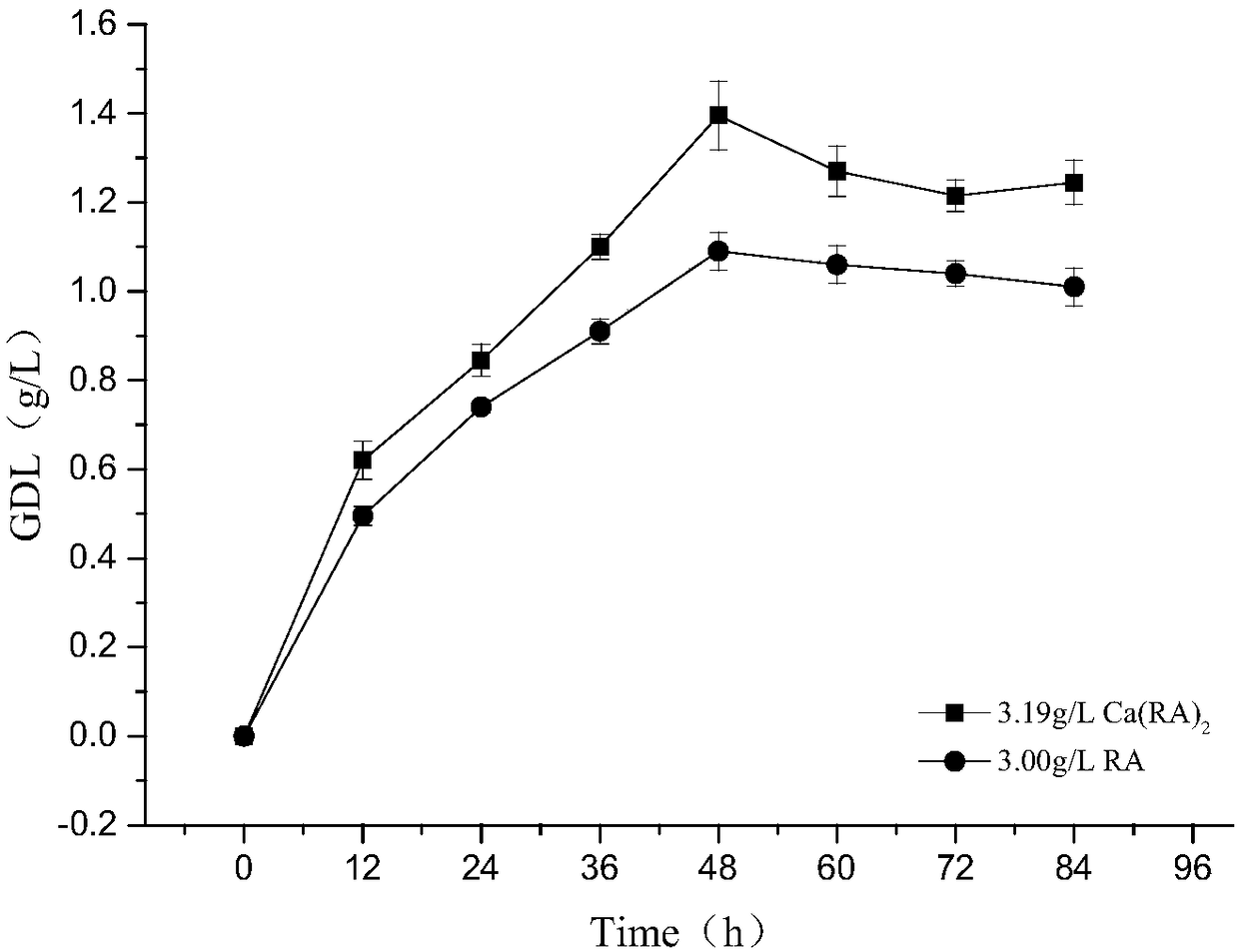

[0030] Embodiment 1 low concentration ricinoleic acid

[0031] A method for preparing natural fragrance gamma-decalactone by microbial fermentation, the specific steps are:

[0032] The used fermentation medium contains ricinoleic acid of 3.00g in every liter of medium, magnesium sulfate heptahydrate of 5.00g, dipotassium hydrogen phosphate of 1.48g, potassium dihydrogen phosphate of 12.45g, 0.10g calcium chloride, 10.00 g of glucose, 0.10 g of L-carnitine, and the pH was adjusted to 5.80; the prepared medium was divided into 250ml shake flasks, and the filling volume of each shake flask was 30mL; Bacteria for 15 minutes, use after cooling.

[0033] Introduced strains: under aseptic conditions, weigh 0.24g of high-activity dry yeast powder, inoculate it into a 250mL Erlenmeyer shaker flask containing 30mL of medium, and mix well.

[0034] Culture conditions: shake the flask into a constant temperature shaker, the shaker speed is 200r / min, the temperature is 28°C, the culture...

Embodiment 2

[0036] Embodiment 2 low concentration calcium ricinoleate

[0037] A method for preparing natural fragrance gamma-decalactone by microbial fermentation, the specific steps are:

[0038] The fermentation medium used contains 5.00g of magnesium sulfate heptahydrate, 1.48g of dipotassium hydrogen phosphate, 12.45g of potassium dihydrogenphosphate, 0.10g of calcium chloride, 10.00g of glucose, 0.10g of L-carnitine, adjust the pH to 5.80; the prepared medium is divided into 250ml shake flasks, and the filling volume of each shake flask is 30mL; the above medium is sterilized at 121°C for 15 minutes, and used after cooling.

[0039] Insert strains: Under sterile operating conditions (in a sterile ultra-clean workbench), weigh 0.24g of high-activity dry yeast powder, inoculate it into a 250mL Erlenmeyer shaker flask containing 30mL of medium, and mix well .

[0040] Adding the substrate: Weigh 0.096 g of calcium ricinoleate (3.19 g / L (equivalent to 3.00 g / L of ricinoleic acid)) und...

Embodiment 3

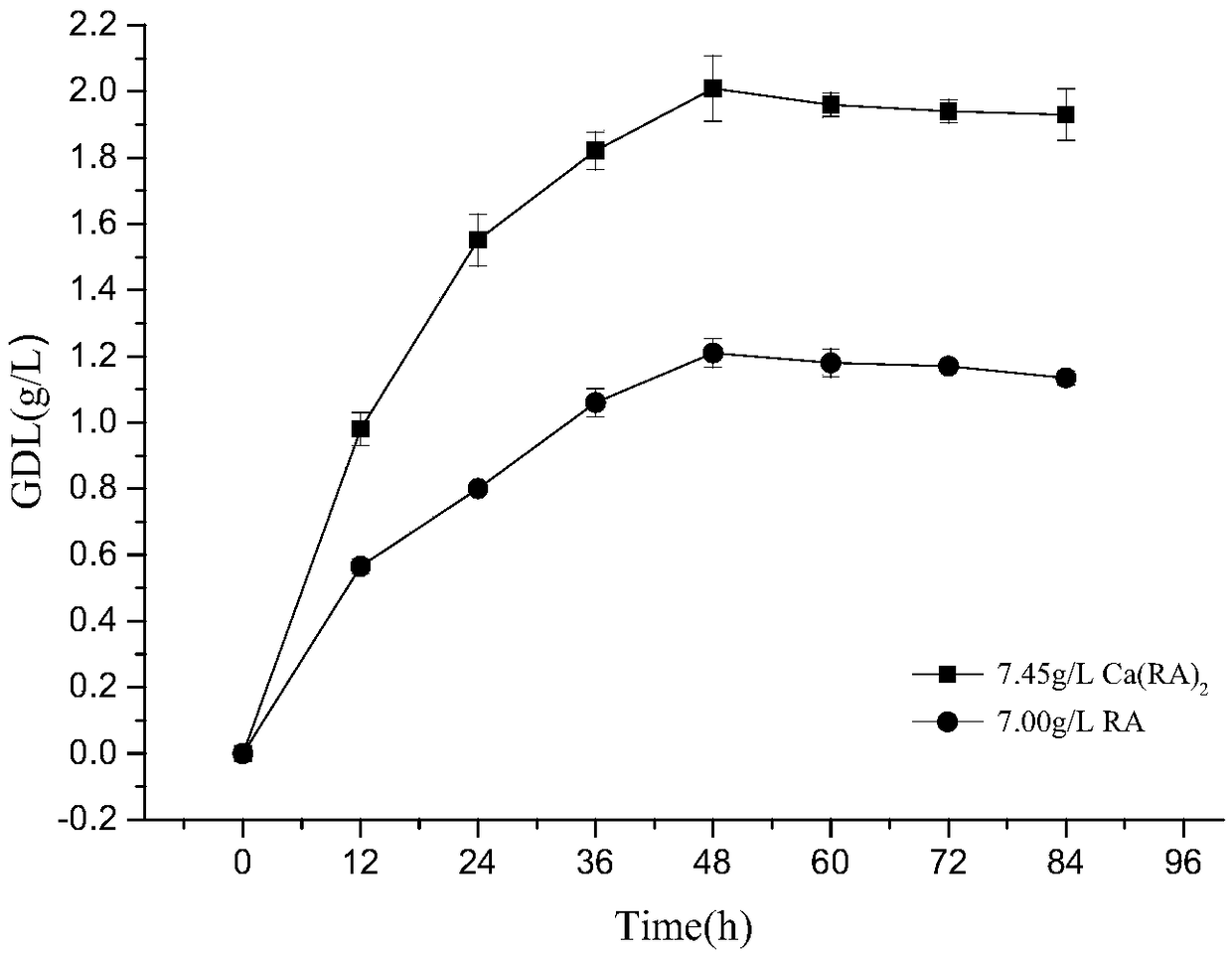

[0043] Concentration ricinoleic acid in embodiment 3

[0044] A method for preparing natural fragrance gamma-decalactone by microbial fermentation, the specific steps are:

[0045] Used fermentation medium, containing the ricinoleic acid of 7.00g in every liter of medium, the magnesium sulfate heptahydrate of 7.50g, the dipotassium hydrogen phosphate of 4.84g, the potassium dihydrogen phosphate of 9.83g, 0.60g calcium chloride, 20.00 g of glucose, 0.15 g of L-carnitine, and the pH was adjusted to 6.20; the prepared medium was divided into 250ml shake flasks, and the filling volume of each shake flask was 30mL; Bacteria for 15 minutes, use after cooling.

[0046] Insert strains: under aseptic conditions, weigh 0.50 g of high-activity dry yeast powder, inoculate it into a 250 mL Erlenmeyer shaker flask containing 30 mL of medium, and mix well.

[0047] Culture conditions: shake the flask into a constant temperature shaker, the shaker speed is 250r / min, the temperature is 32°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com