Chain tightener, chain transmission mechanism with same and tobacco cutting device

A technology of chain tensioner and chain transmission, applied in the direction of transmission, tobacco, application, etc., can solve the problem that the chain transmission mechanism is easily damaged by reverse rotation, and achieve the effect of avoiding over-tensioning and over-feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

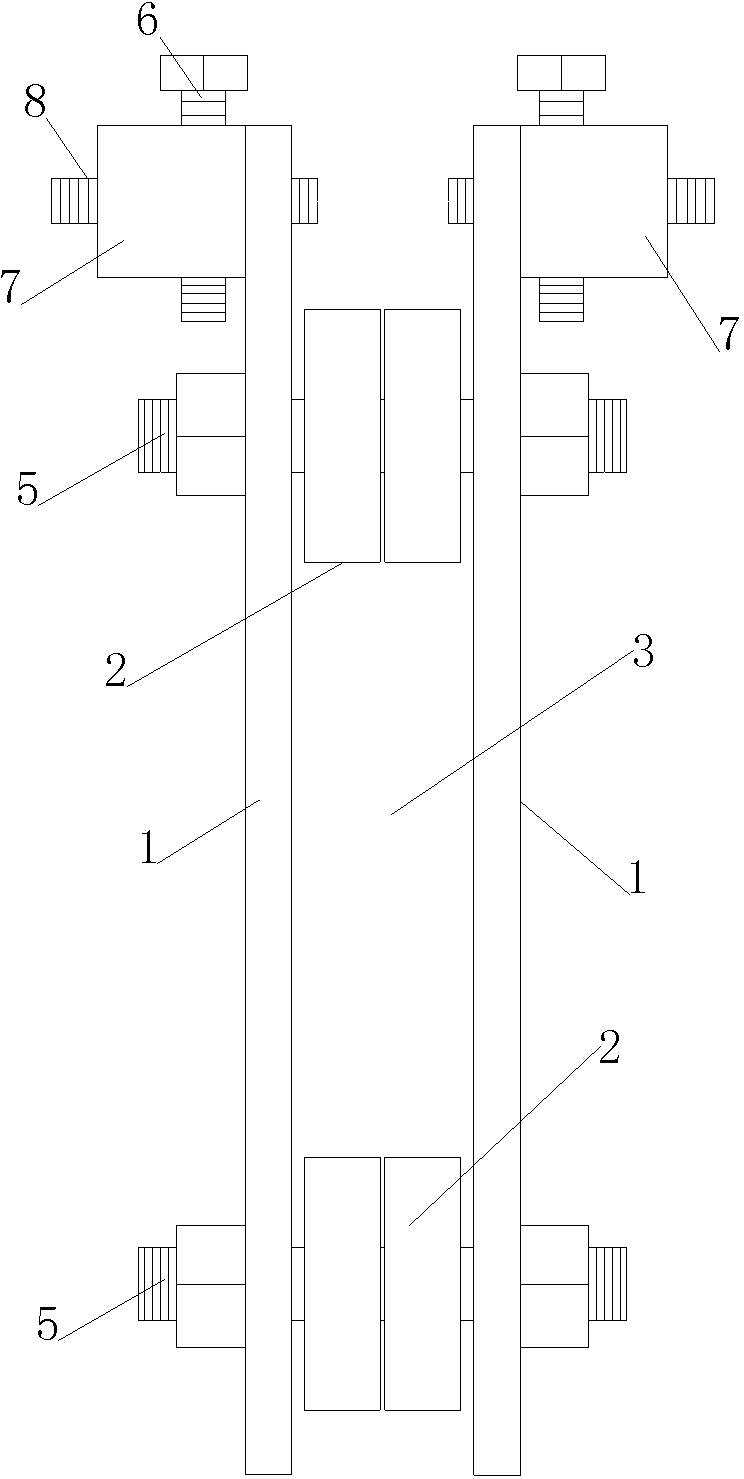

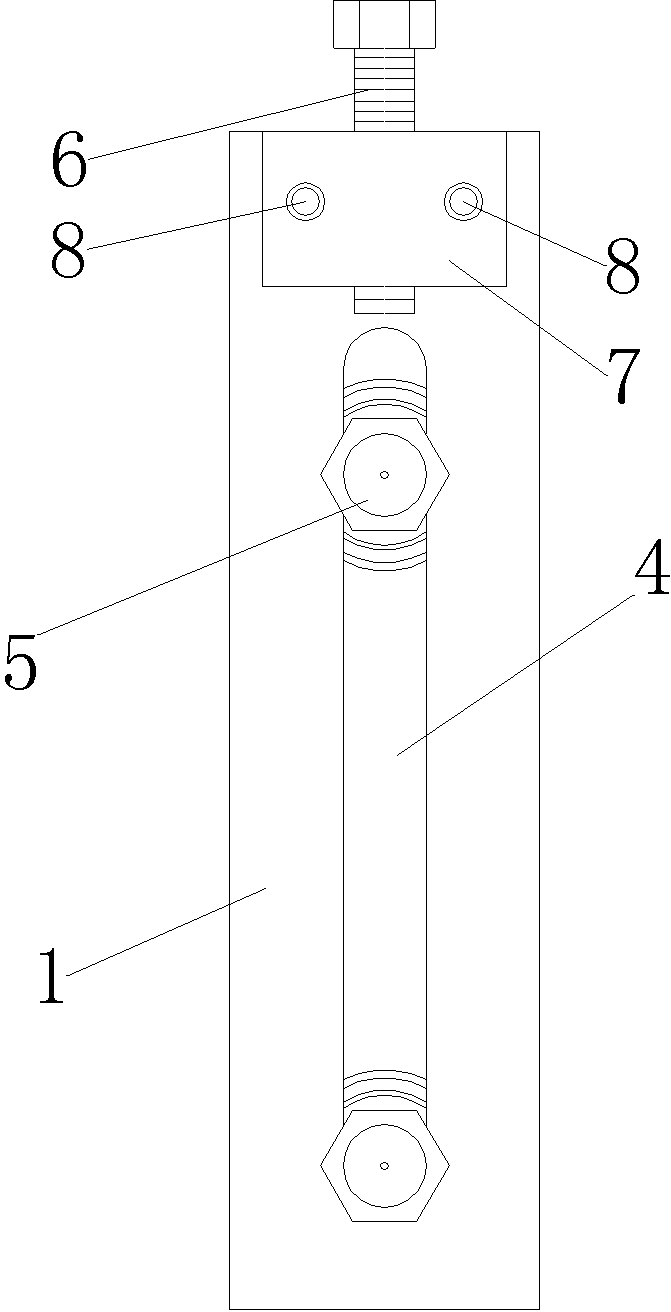

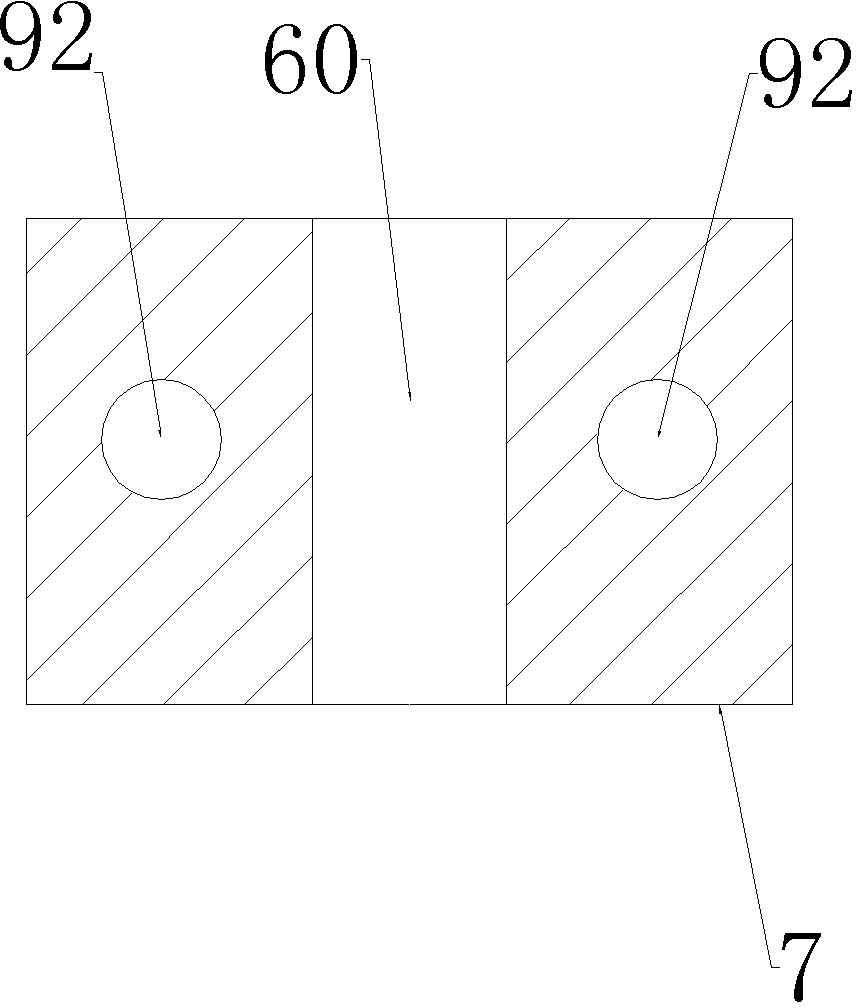

[0020] Embodiment 1 of the chain tensioner of the present invention, such as Figure 1-4 Shown: the chain tensioner includes two splints 1 and two tensioning wheels 2. Two splints 1 are arranged parallel to each other at intervals on the left and right, and each splint 1 is arranged vertically. Two tensioning wheels 2 are arranged between two clamping plates, and the tensioning wheels 2 are rotatably assembled on the clamping plates.

[0021] When in use, the thickness of the transmission chain extends along the up and down direction, and the transmission chain can move along the front and rear directions. Carry out upper and lower tensioning action to transmission chain 1. The two splints 1 and the two tension wheels 2 together form a channel 3 for the transmission chain to pass through.

[0022] Each splint 1 is provided with an adjusting long hole 4 for adjusting the distance between the axles of the two tensioning wheels, and the tensioning wheel 2 is assembled on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com