Vibration sieve

A technology of vibrating screen and screen body, which is applied in the field of color sorter, can solve the problems of uneven cutting, color sorting machine, color sorting, etc., and achieve the effect of ensuring uniformity, improving work efficiency, and uniform cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

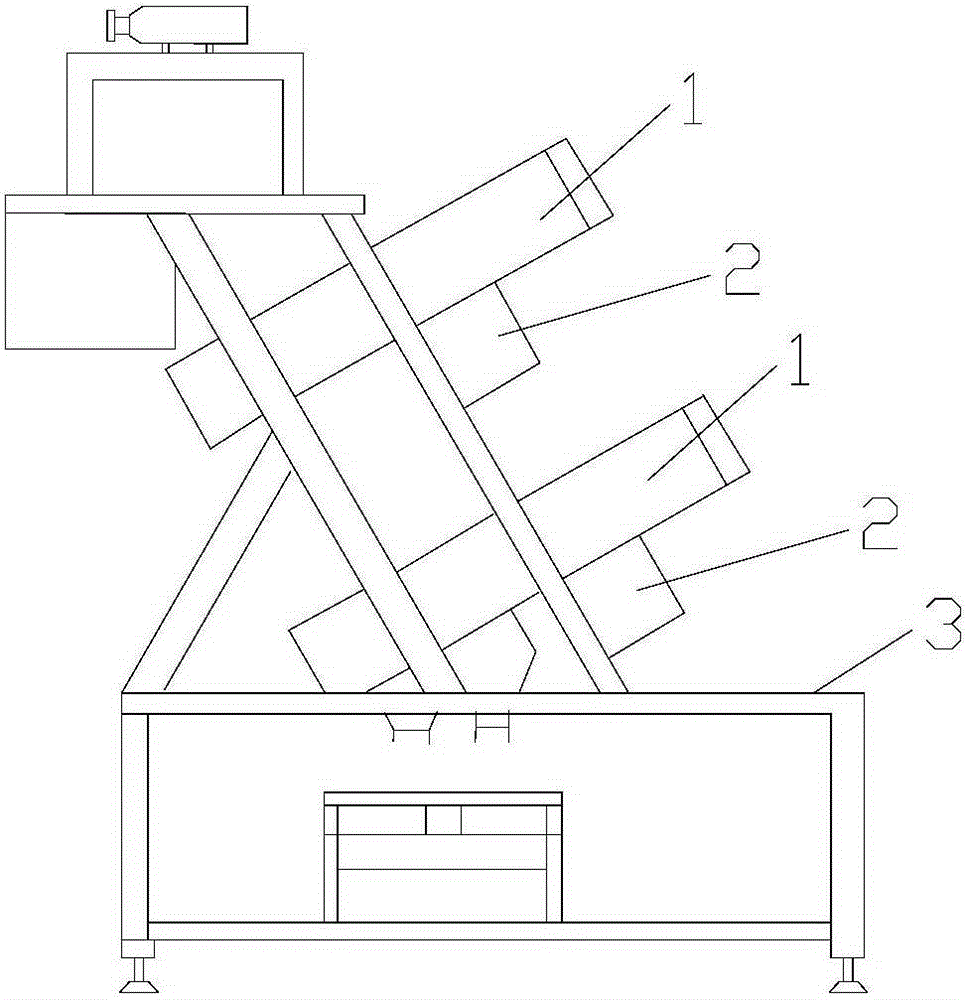

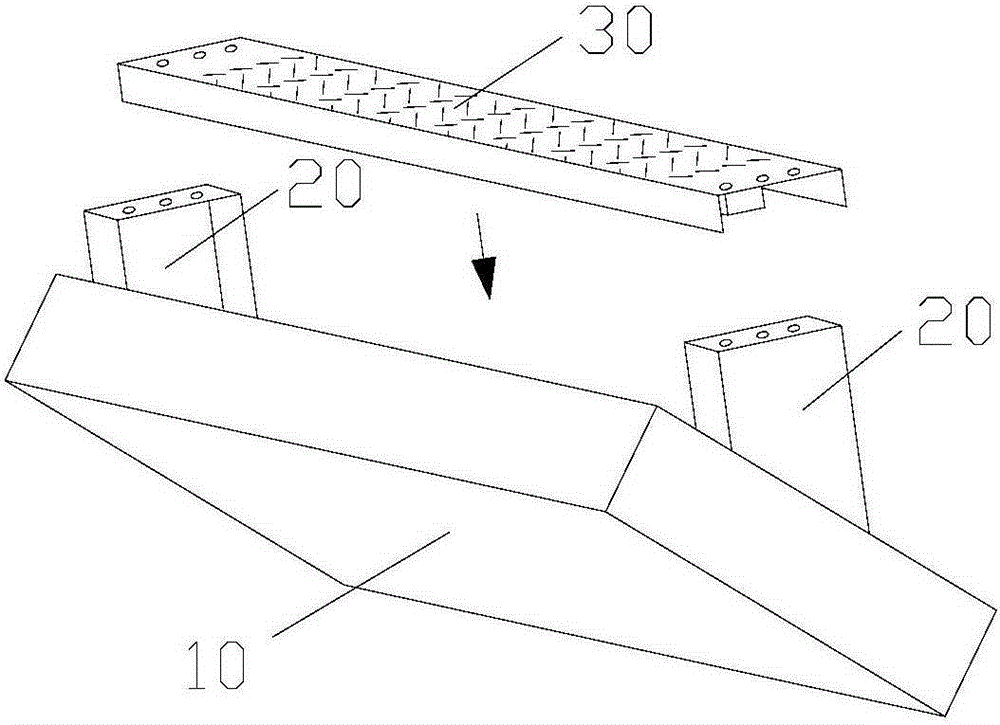

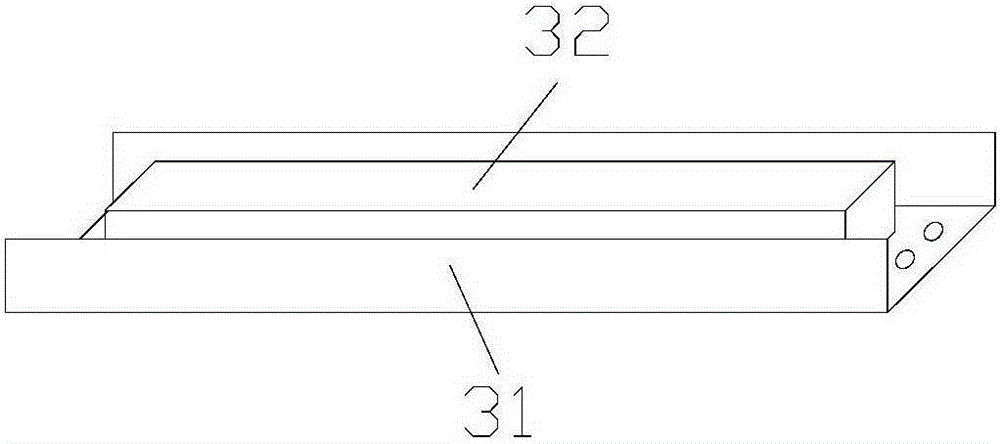

[0011] Such as Figure 1-2 Shown: a vibrating screen, including a square sieve body with a feed section 10 and a discharge section, the sieve body is surrounded by a baffle plate 20, and the discharge section includes 5 discharge ports 30, evenly distributed partitions 40 are arranged between each discharge port 30, the discharge side 31 of the discharge port 30 is arranged obliquely to the flow direction of the material and the discharge side 31 of each discharge port 30 is inclined The angles are consistent, and the connection line 41 between the partition 40 and the discharge side 31 is set parallel to the flow direction of the material. In actual work, the vibrating screen is installed on the vibrating device on the top of the color sorter. The vibrating device vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com