Livestock feed casting device and livestock feed casting method

A livestock and feed technology, used in animal feeding devices, animal husbandry, non-electric variable control, etc., can solve the problems of excessive feeding, deterioration, and waste of feed, and reduce the waste of feed and the possibility of deterioration. , to avoid the effect of overfeeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

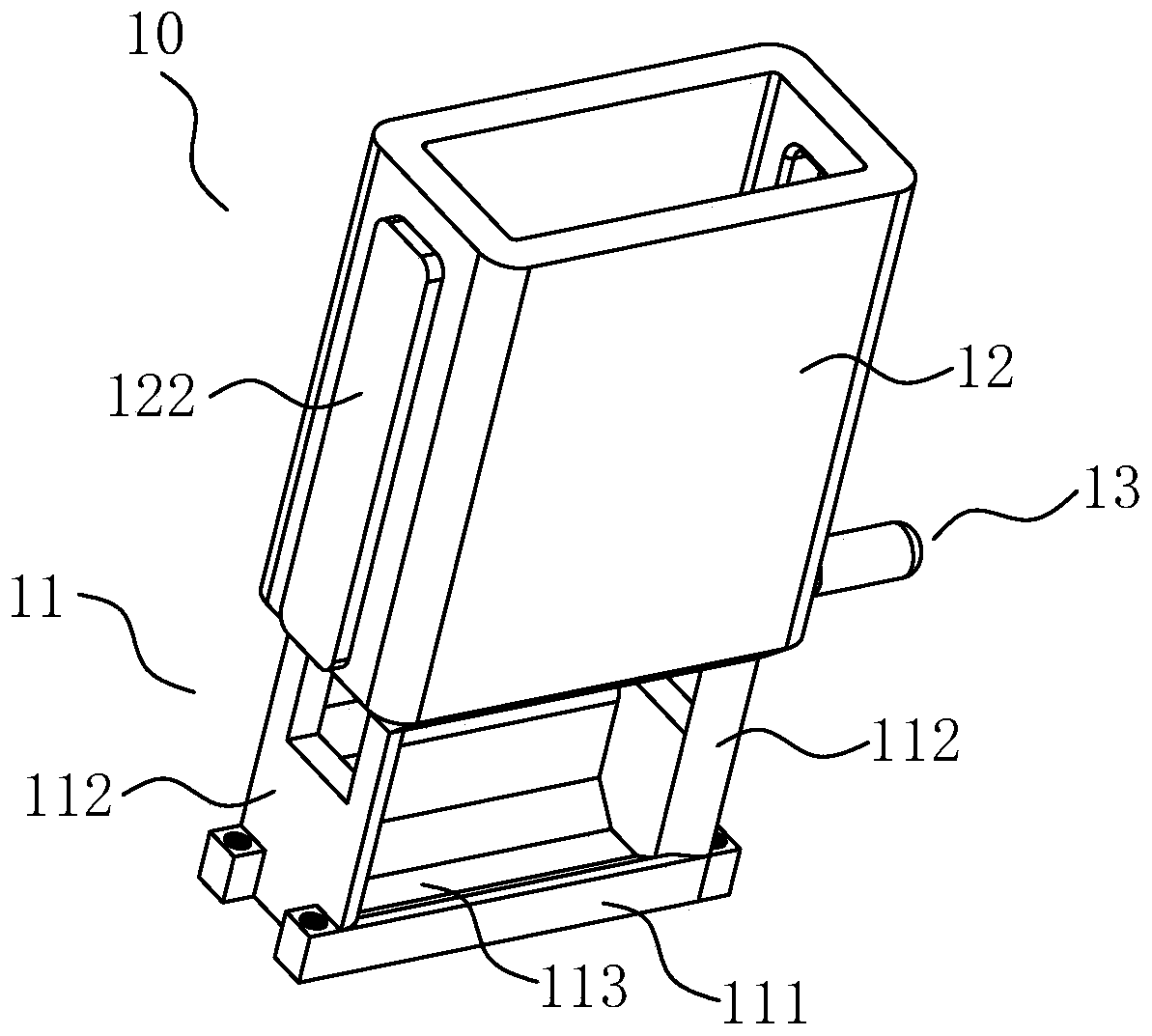

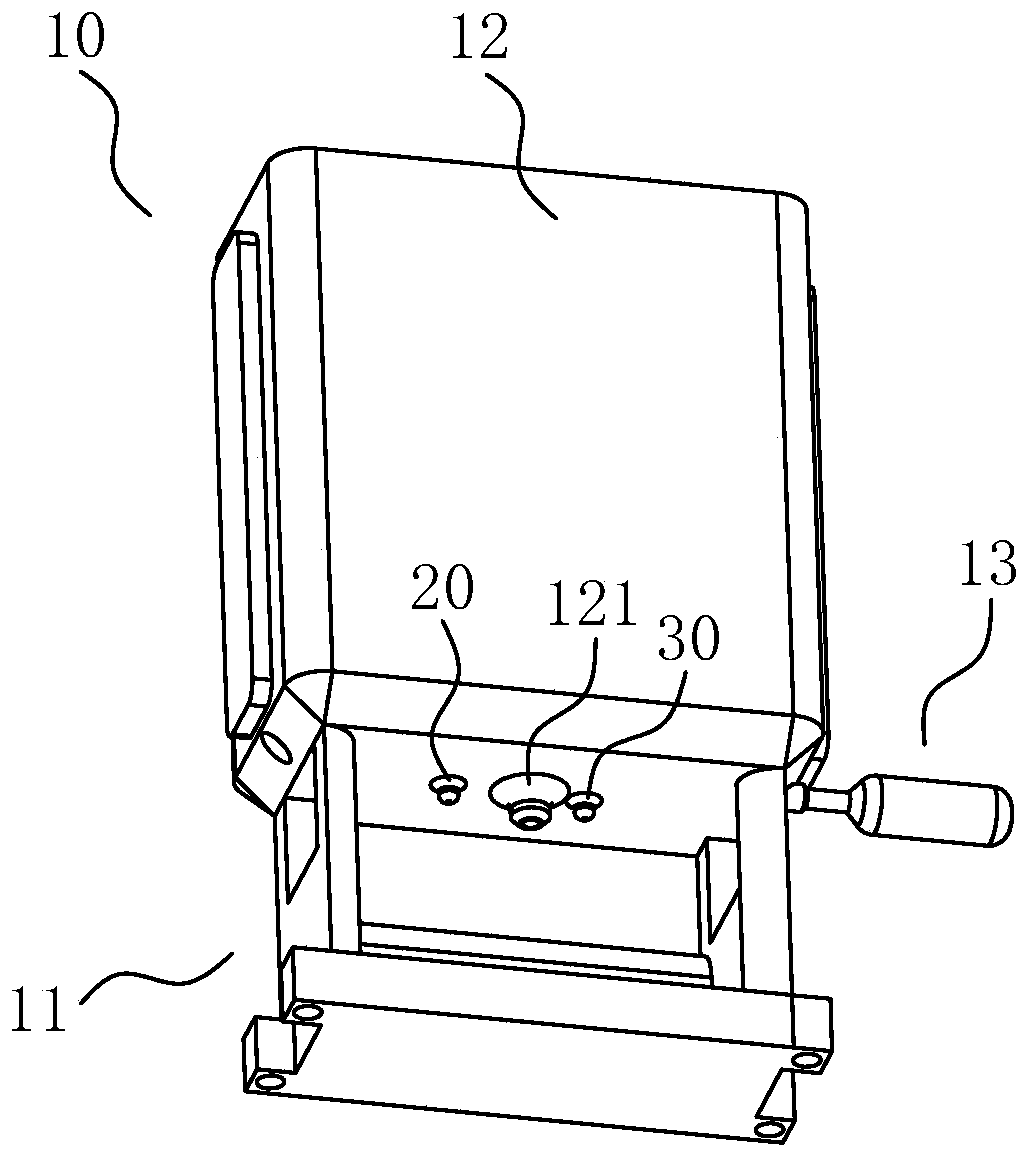

[0047] see figure 1 with figure 2 , figure 1 with figure 2 Schematic diagrams of the structure of the feed feeding device for livestock from different perspectives provided in the embodiments of the present application.

[0048] The livestock feed feeding device of the embodiment of the present application includes a livestock feed feeding mechanism 10, a livestock sensor 20, a trough inventory sensor 30 and a control module (not shown in the figure),

[0049] The livestock feed feeding mechanism 10 includes a trough 113 and a discharge port 121, and the discharge port 121 is provided with a discharge valve (not shown in the figure);

[0050] The livestock sensor 20 is arranged on the livestock feed feeding mechanism 10, and is used to sense whether there are livestock in the target feeding area;

[0051] The trough inventory sensor 30 is located on the livestock feed feeding mechanism 10, and is used to sense the feed inventory of the trough 113;

[0052] The control m...

Embodiment 2

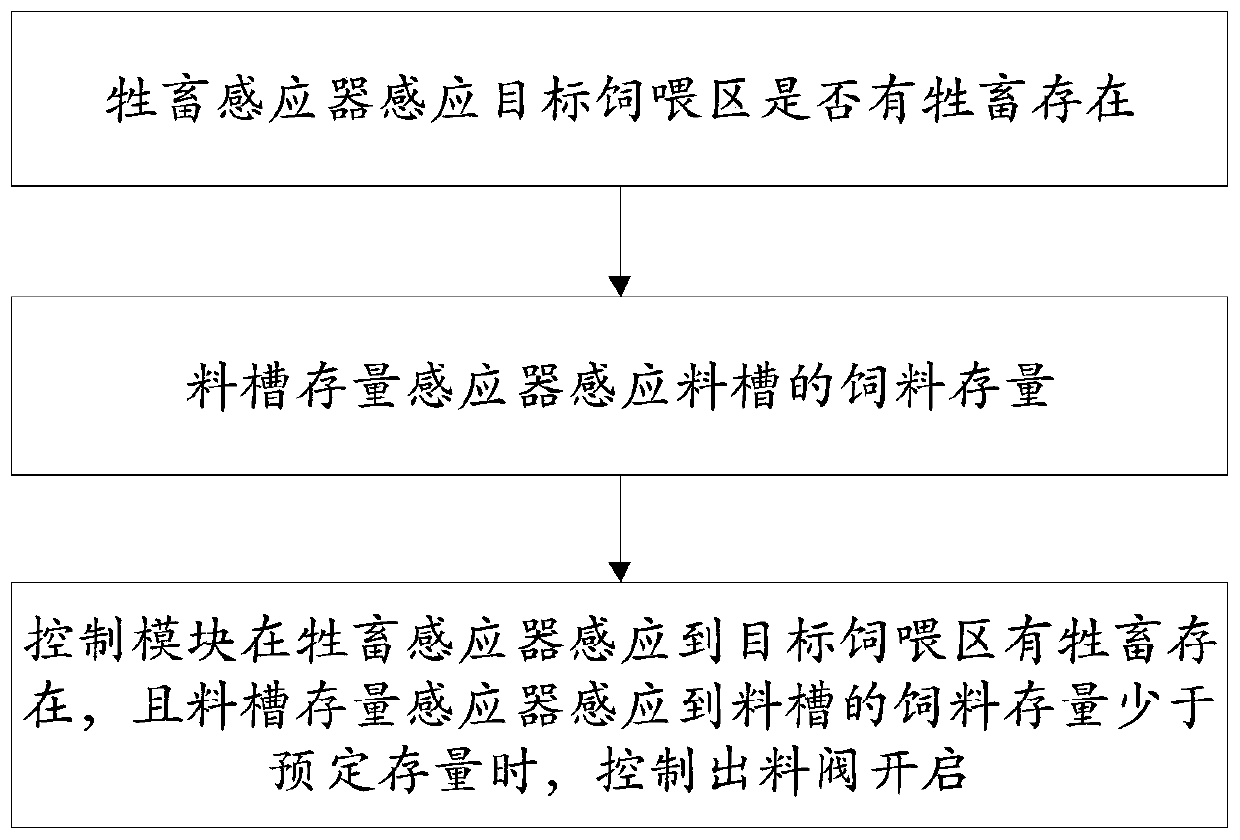

[0078] see Figure 1 to Figure 3 ,in, figure 1 with figure 2 Schematic diagram of the structure of the livestock feed feeding device under different perspectives provided by the embodiment of the present application, image 3 It is a schematic flow chart of the livestock feed feeding method provided in Example 2 of the present application.

[0079] The embodiment of the present application provides a livestock feed feeding method, which is applied to the livestock feed feeding device in the first embodiment above.

[0080] For the content of the feed feeding device for livestock in the embodiment of the present application, reference may be made to the specific content of the first embodiment above, and details are not repeated here.

[0081] The livestock feed feeding method of the embodiment of the present application includes:

[0082] Livestock sensor 20 senses whether there are livestock in the target feeding area;

[0083] Feed tank stock sensor 30 induction feed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com