Cave-type accurate automatic bait feeder

An automatic bait feeding and precise technology, which is applied in the field of bait feeding machine manufacturing and electronic circuit automatic control, can solve the problems of low feeding precision, single bait type, and large bait waste, so as to achieve the optimization of feeding effect and the improvement of bait feeding. Accurate, high feeding precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

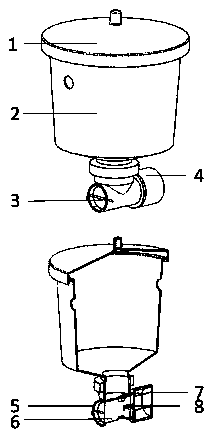

[0024] refer to figure 1 As shown, the structure of a slot-type precision automatic bait feeding machine includes a storage bin part and a feeding feeding part connected to the lower opening of the storage bin.

[0025] refer to figure 1 As shown, the storage bin part of a slot-type precision automatic bait feeding machine includes a bin (2) and a bin cover (1). The volume of the feed bin (2) can be customized according to different breeding sites and different breeding varieties. Since the silo cover (1) has a downwardly bent outer edge, and the diameter of the outer edge of the silo cover (2) is larger than the diameter of the mouth of the silo (1), the silo cover (1) can be easily Good barrier to entry of solid or liquid contaminants into the silo (2).

[0026] refer to figure 1 As shown, the feeding and unloading part of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com