Novel cane harvester

A harvester, sugarcane technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of low efficiency, high sugarcane damage rate and waste rate, and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

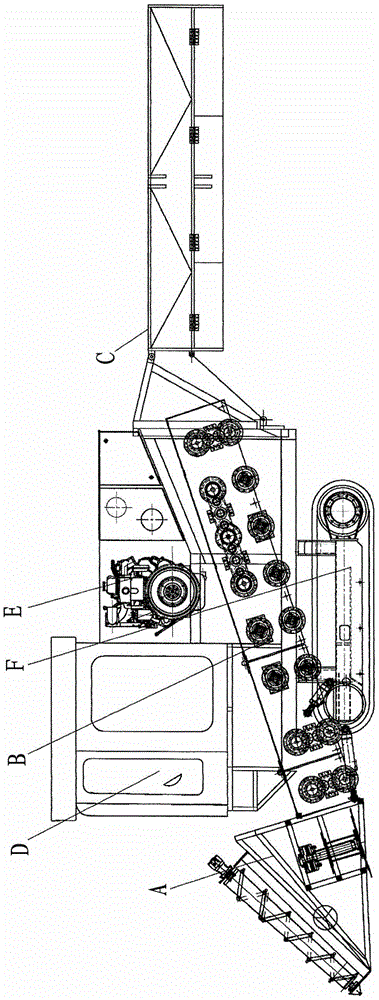

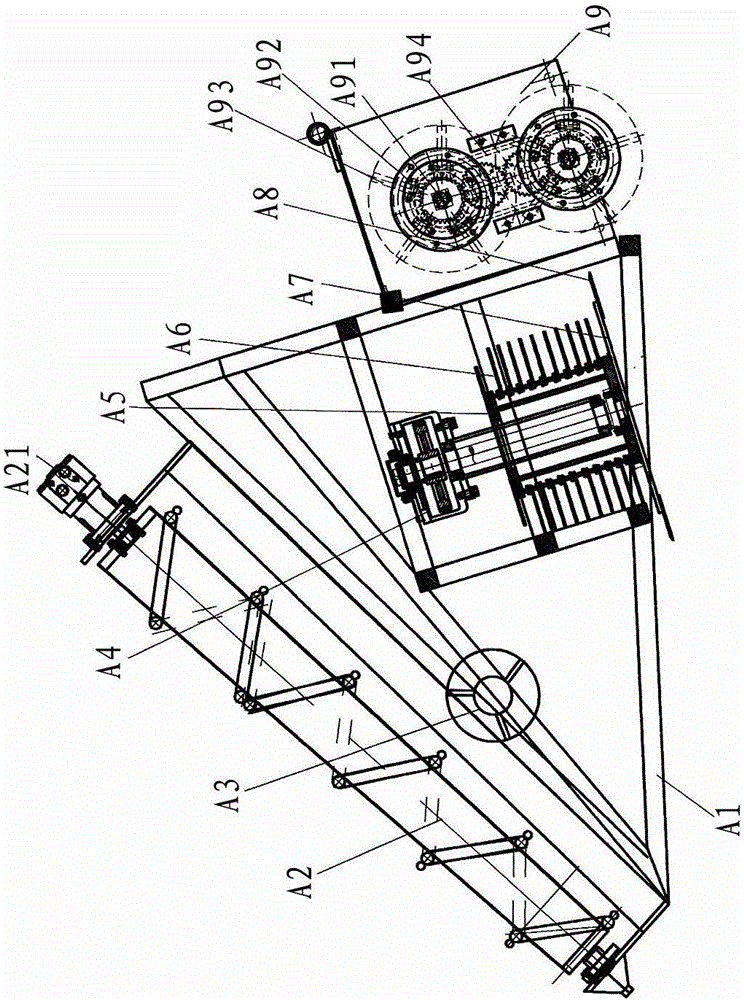

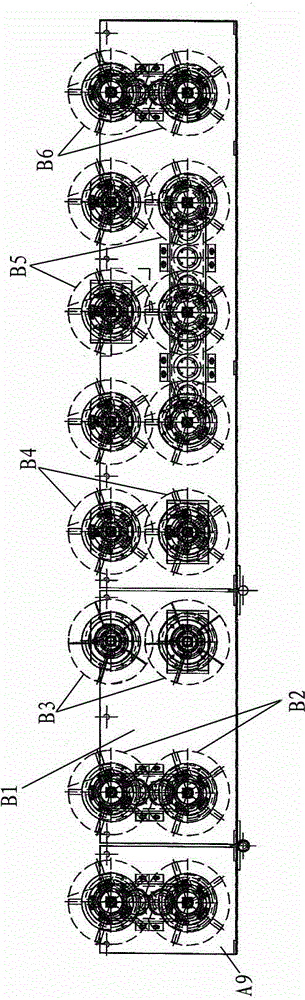

[0061] Such as figure 1 As shown, a new type of sugarcane harvester is composed of a control mechanism, a hydraulic system E, a feeding and conveying mechanism B, a discharge hopper C, and a walking mechanism F. It is characterized in that a walking mechanism F is provided below the chassis, There is a feeding conveying mechanism B on the upper side, and the discharge hopper C is gradually inclined upward from the inside out. The tops of the left and right sides of the inner end of the discharge hopper C are respectively fastened to the rear of the feeding conveying mechanism B by steel plates, and the inner side of the discharge hopper C The waists on the left and right sides of the end support an angle adjustment cylinder. The angle adjustment cylinder can adjust the inclination angle of the unloading hopper C. The header A arranged at the front end of the feeding and conveying mechanism B cuts off the root of the sugar cane rod and sends it into the conveying channel. After t...

Embodiment 2

[0091] In this embodiment, only the structure of the discharge hopper is different from the first embodiment, and the rest is the same as the first embodiment.

[0092] Such as Image 6 As shown, in the single-opening unloading hopper C, only the left side baffle or the bottom of the right side baffle is movably connected with an arc-shaped opening and closing bottom plate C2 through a plurality of loose leaves, and this arc-shaped opening and closing bottom plate C2 passes through the opening and closing cylinder C3 The opening or closing is completed separately, and the bottom of the side baffle C1 that is not connected to the arc-shaped opening and closing bottom plate C2 is bent inward, and the ratio between the bent part and the arc-shaped opening and closing bottom plate C2 is 3:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com