Straddle-type movable-butting track beam and use method thereof

A track beam and straddle technology, applied in tracks, roads, buildings, etc., can solve problems such as affecting the landscape of vehicle bases and increasing engineering investment, and achieve the effect of facilitating crossing of roads, saving engineering investment and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

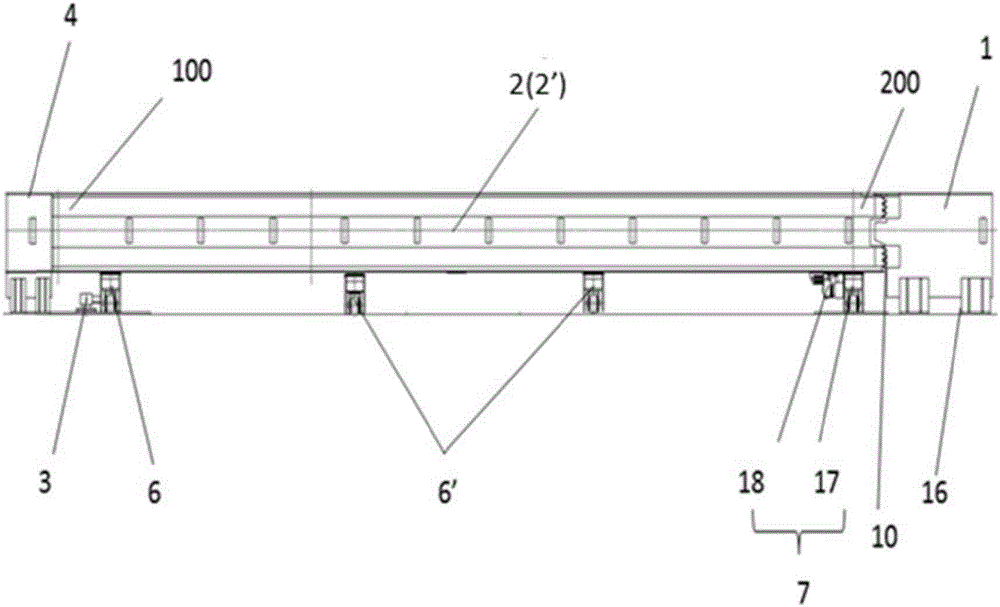

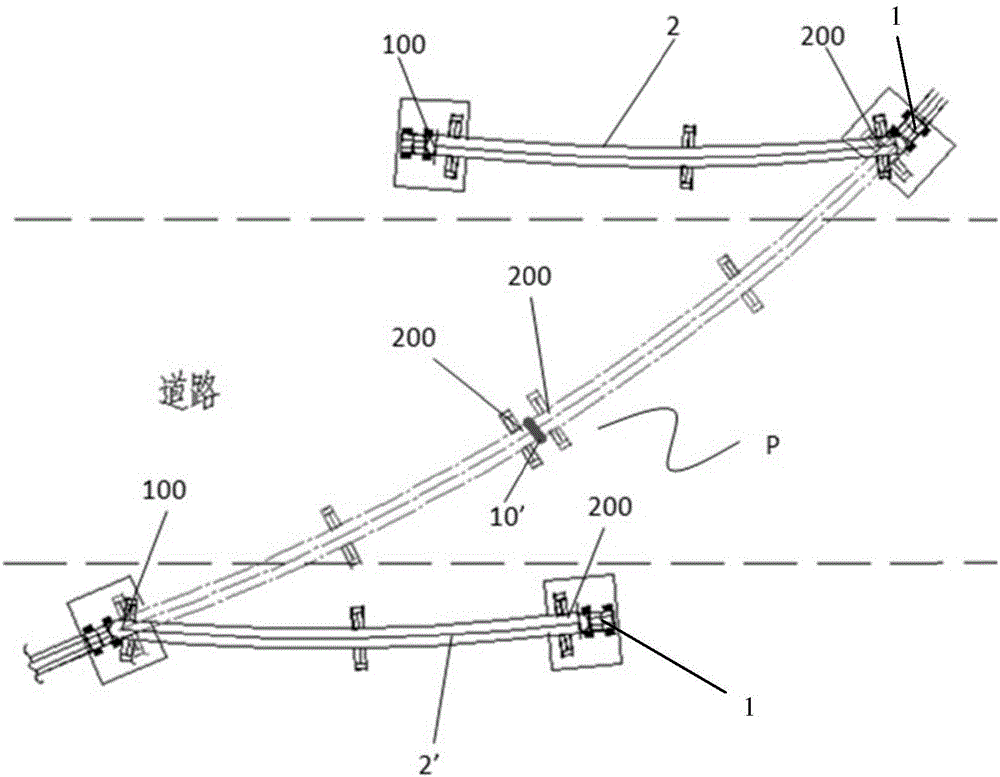

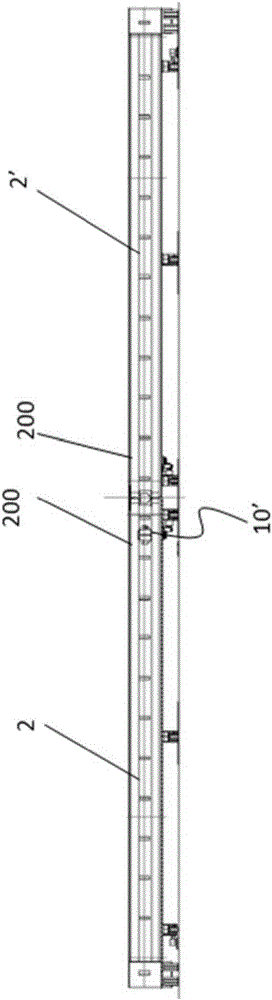

[0037] like Figure 1-3 As shown, the straddle-type movable docking track beam of the present invention includes a first track beam 2, a second track beam 2', a driving device 7 and a rotating device 3, and the first track beam 2 and the second track beam 2 ' have the same structure, both have a pivot end 100 and a movable end 200, and the first track beam 2 and the second track beam 2' are respectively arranged on both sides of the road;

[0038] The two groups of driving devices 7 are respectively connected to each of the movable ends 200 (or positions close to the movable ends 200, as long as it is convenient to push the movable ends 200 to swing), and are used to drive the track beams 2 and 2' Swing with the pivot end 100 as the center of rotation;

[0039] The two groups of rotating devices 3 are connected to the pivot ends 100 respectively, and are used to rotate under the drive of the driving device 7;

[0040] The movable ends 200 of the first track beam 2 and the se...

Embodiment 2

[0053] like Figure 5 As shown, the present invention also provides a method for using the above-mentioned straddle-type movable track beam that can cross the road, which includes the following steps:

[0054] S1, release the locking of the first locking device 10 of the movable end 200 of the first track beam 2 and the second track beam 2' according to the instruction;

[0055] S2. The driving device 7 releases the power to drive the movable ends 200 of the first track beam 2 and the second track beam 2' to swing with the respective pivot ends 100 as the center of rotation;

[0056] S3. The movable ends 200 of the first track beam 2 and the second track beam 2' drive the respective pivot ends 100 to rotate, so that the movable ends 200 of the first track beam 2 and the second track beam 2' Docking is carried out under the drive of the driving device 7 to form a running line P across the road;

[0057] S4. After the movable ends 200 of the first track beam 2 and the second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com