Bridge bottom surface crack width measurement device

A crack width and measuring device technology, which is applied to measuring devices, mechanical measuring devices, and optical devices, etc., can solve problems such as inappropriate use of large bridge inspection vehicles and frequent crack detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

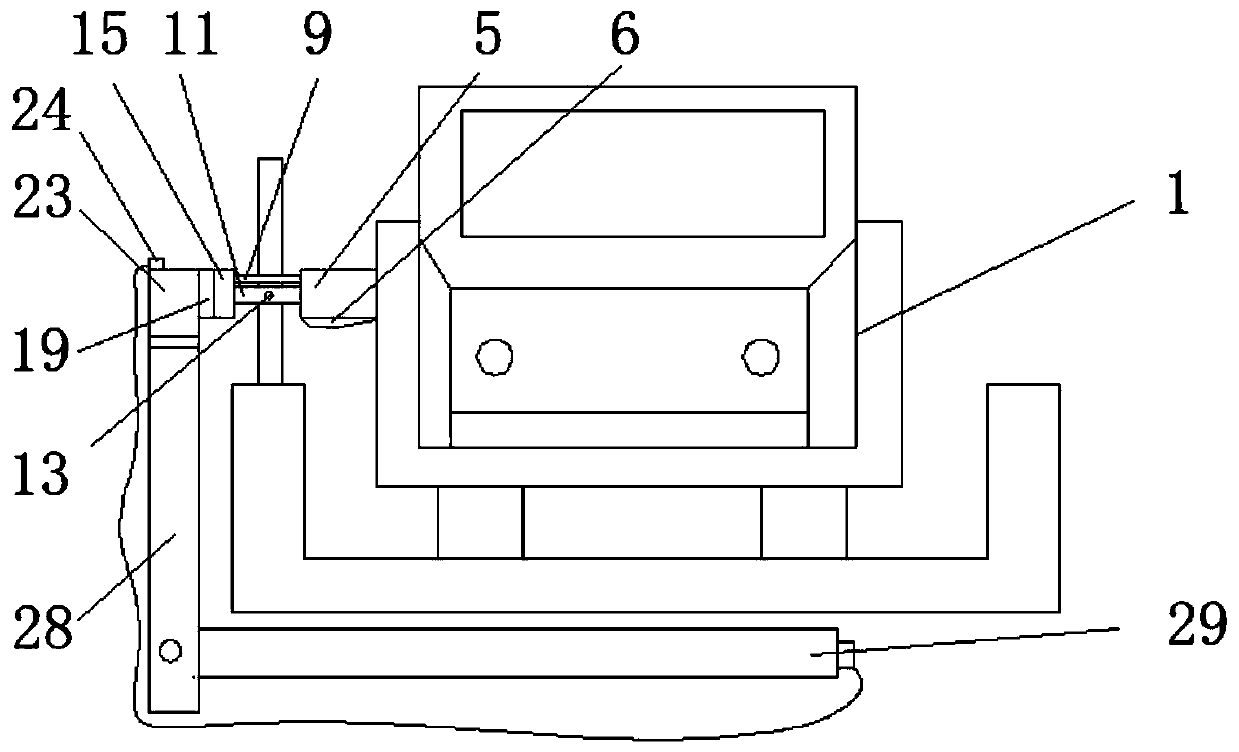

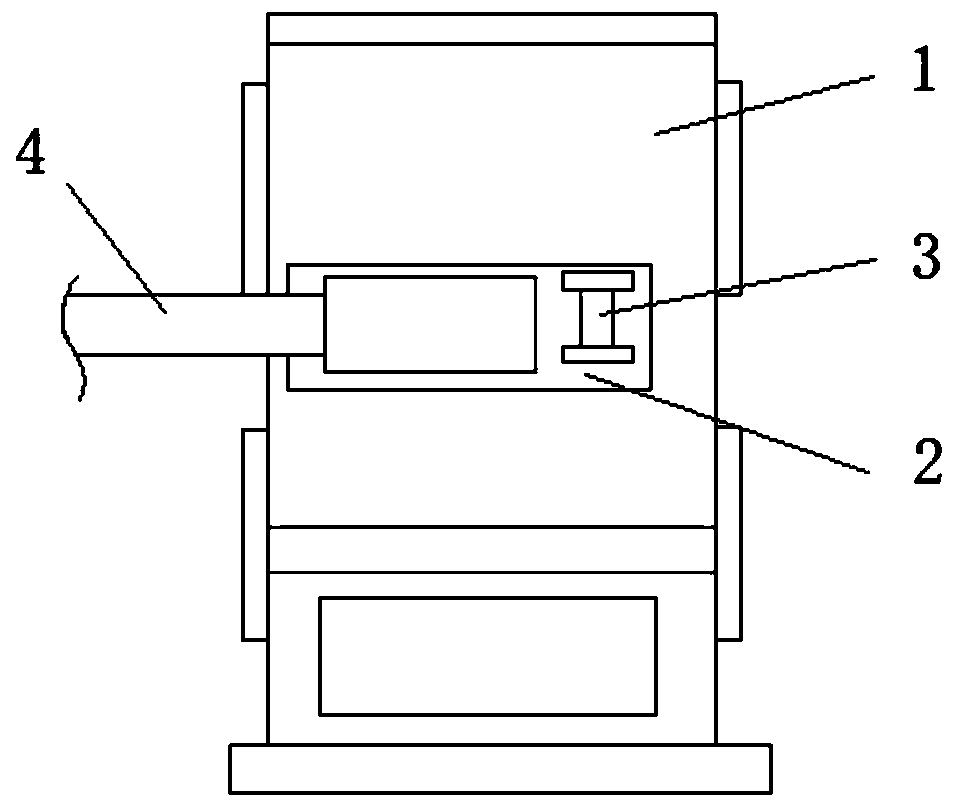

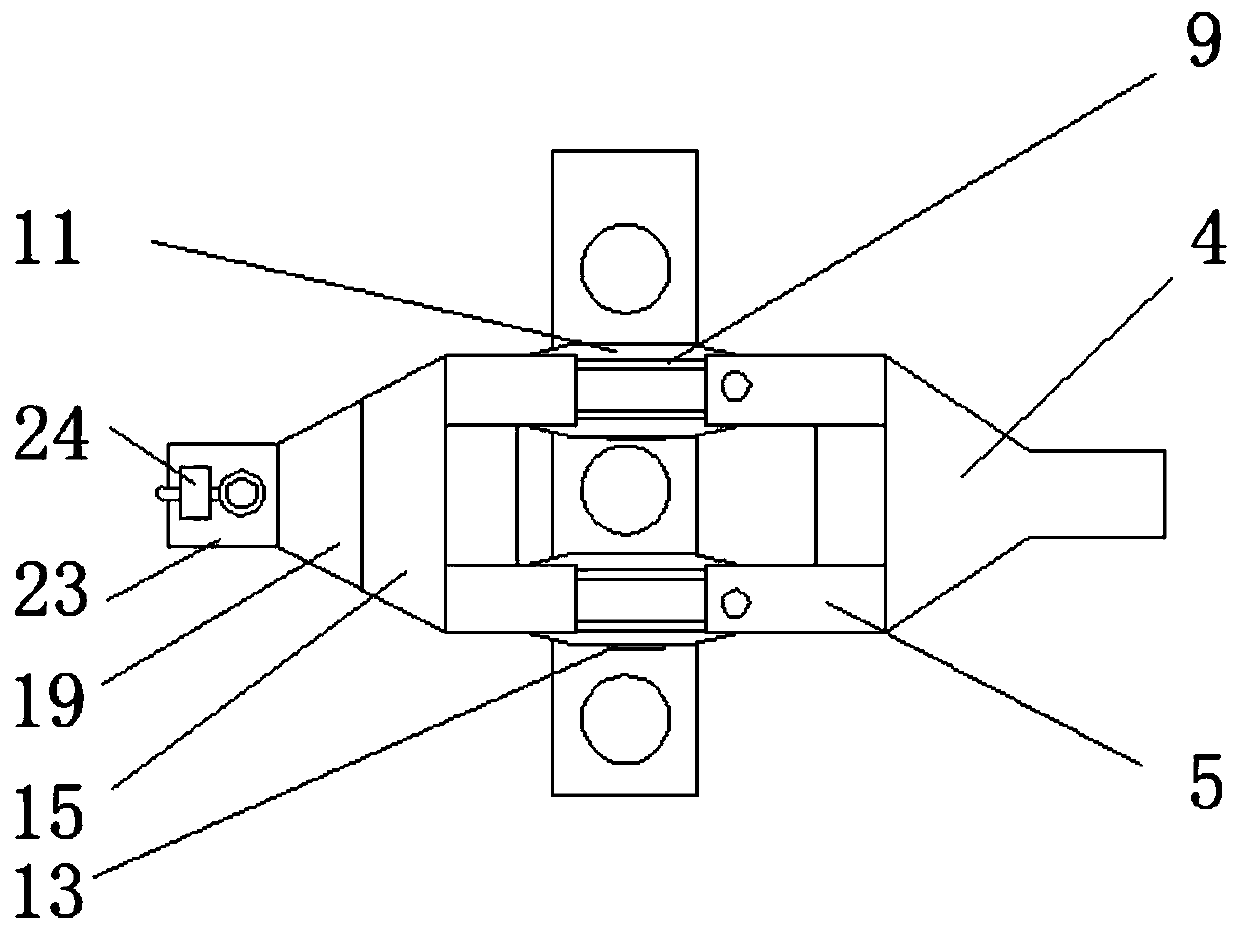

[0030] refer to Figure 5-6, different from Embodiment 1, the side of the second main arm 19 is fixedly connected with a control box 23, the upper surface of the control box 23 is fixedly connected with a fixed cable block 24, and the inside of the control box 23 is fixedly connected with a micro servo motor 25, The lower surface of the control box 23 is provided with an annular groove 26, the interior of the annular groove 26 is fixedly connected with a slider 27, the lower surface of the slider 27 is fixedly connected with a vertical rod 28, and the back of the vertical rod 28 is rotatably connected with a horizontal block 29 , the upper surface of the horizontal block 29 is provided with a movable groove 30, the inside of the movable groove 30 is slidably connected with a distance sensing device 31, and the upper surface of the distance sensing device 31 is fixedly connected with a high-definition camera device 32 and an illuminating lamp 33 respectively, and the distance se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com