One-time reaction extrusion forming production line for acrylic plates

A technology of extrusion molding and secondary reaction, which is applied in the direction of application, flat products, chemical/physical/physicochemical processes, etc. It can solve the problems of increasing production cost, high production cost, production cycle, and cost increase, and achieves an increase in polymerization speed. Good effect with efficiency and molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

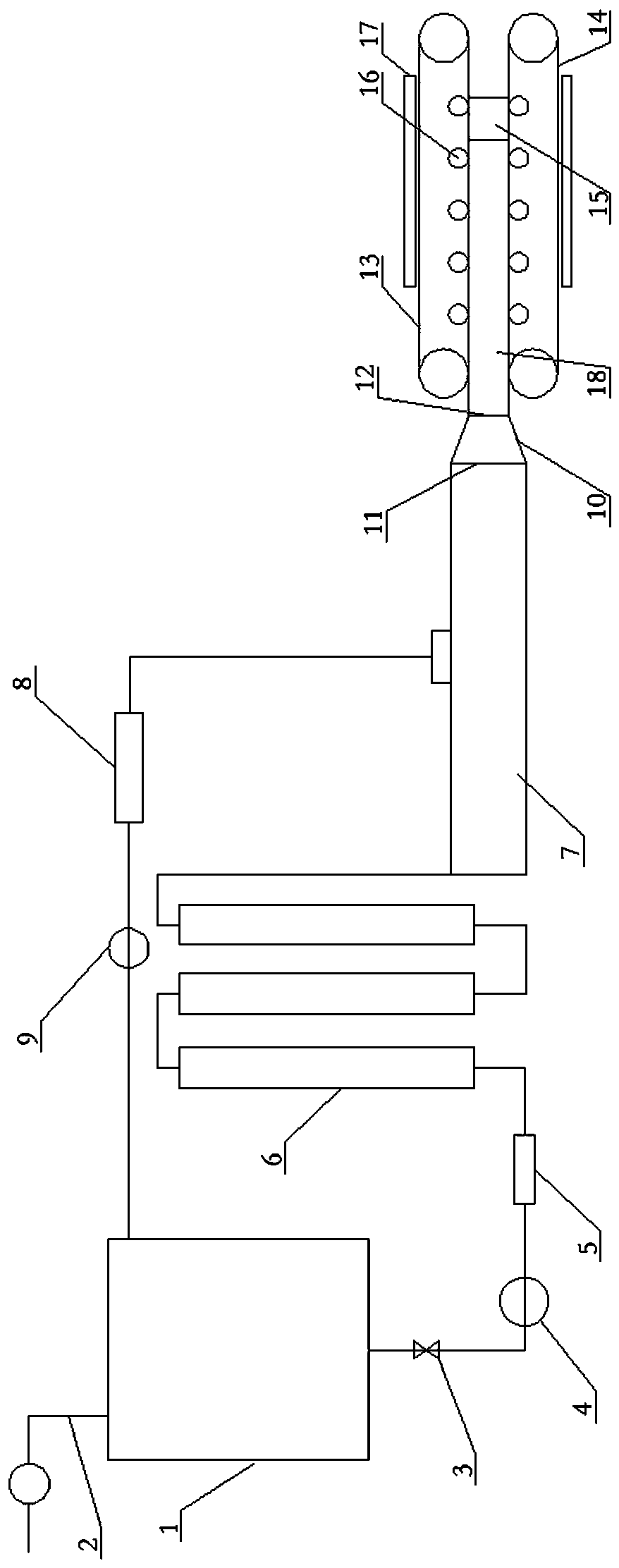

[0027] figure 1 Shown: a one-time reaction extrusion molding production line for acrylic sheets, including a reactor 1, an MMA feed pipe 2, a discharge valve 3, a feed flow meter 4, an initiator additive 5, a tubular reactor 6, a screw Devolatilization device 7, condenser 8, return liquid flow meter 9, even material feeding cylinder 10, upper endless conveyor belt 13, lower endless conveyor belt 14, sealing head baffle 15, roller body 16, heating zone 17, gap space Cavity 18. The upper part of the reaction kettle 1 is connected with the MMA feed pipe 2 with a flowmeter, and the lower part of the reaction kettle 1 is connected in series with the initiator additive 5 and a plurality of tubular reactors 6 through the discharge valve 3 and the feeding flowmeter 4, and then connected with the screw discharger. The inlet of the volatilization device 7, the exhaust port of the screw devolatilization device 7 is connected to the upper part of the reaction kettle 1 through the condens...

Embodiment 2

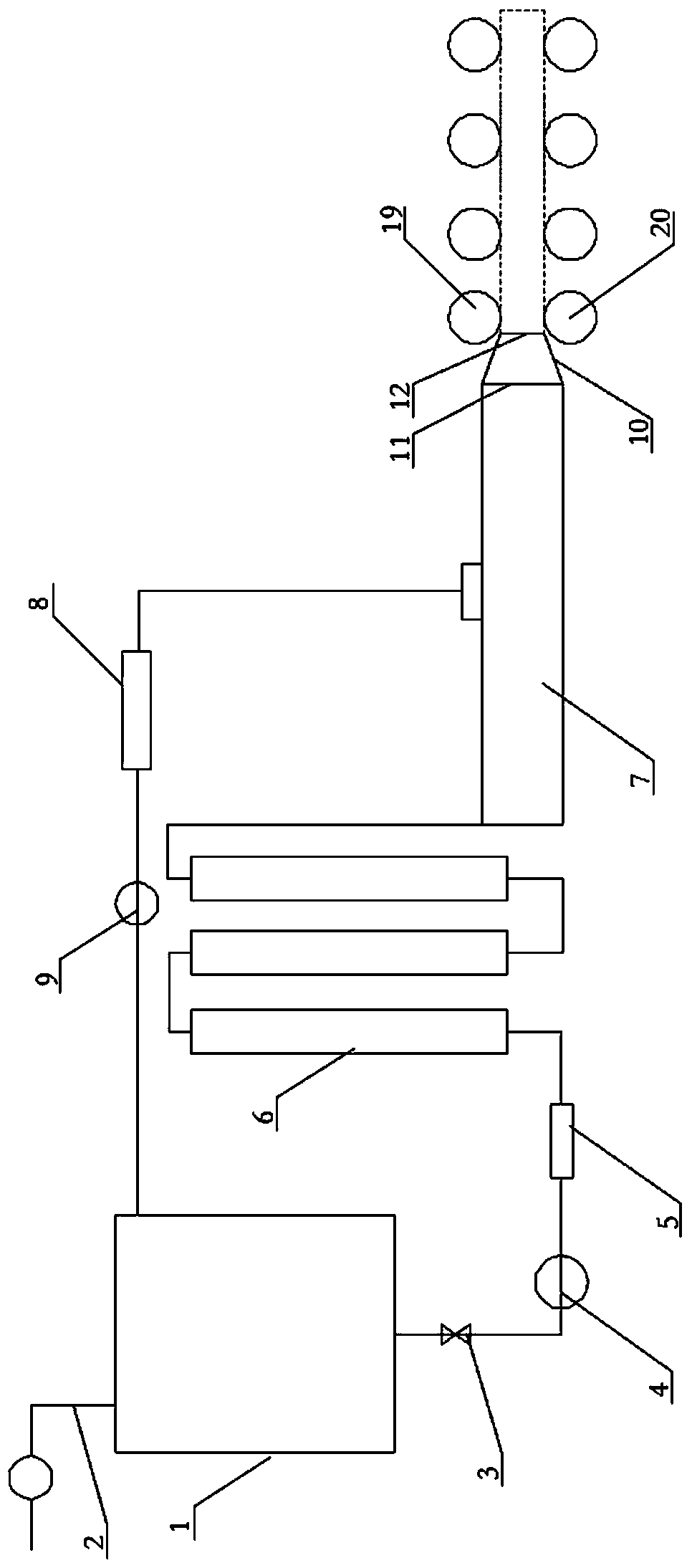

[0029] figure 2 Shown: a one-time reaction extrusion molding production line for acrylic sheets, including a reactor 1, an MMA feed pipe 2, a discharge valve 3, a feed flow meter 4, an initiator additive 5, a tubular reactor 6, a screw Devolatilization device 7, condenser 8, liquid return flow meter 9, leveling feeding cylinder 10, upper forming roller 19, lower forming roller 20. The structure from the reaction kettle 1 to the leveling feeding cylinder 10 is the same as that of the first embodiment. The horizontal square strip-shaped outlet at the other end of the leveling material feeding cylinder is directly discharged. Corresponding to the horizontal square strip-shaped exit, multiple groups of upper and lower gap spaces are set. , lower forming rollers 19,20, multiple groups of upper and lower forming rollers 19,20 are arranged along the plate forming direction of the discharge conveying plate, and the upper and lower forming rollers 19,20 are driven to press and form th...

Embodiment 3

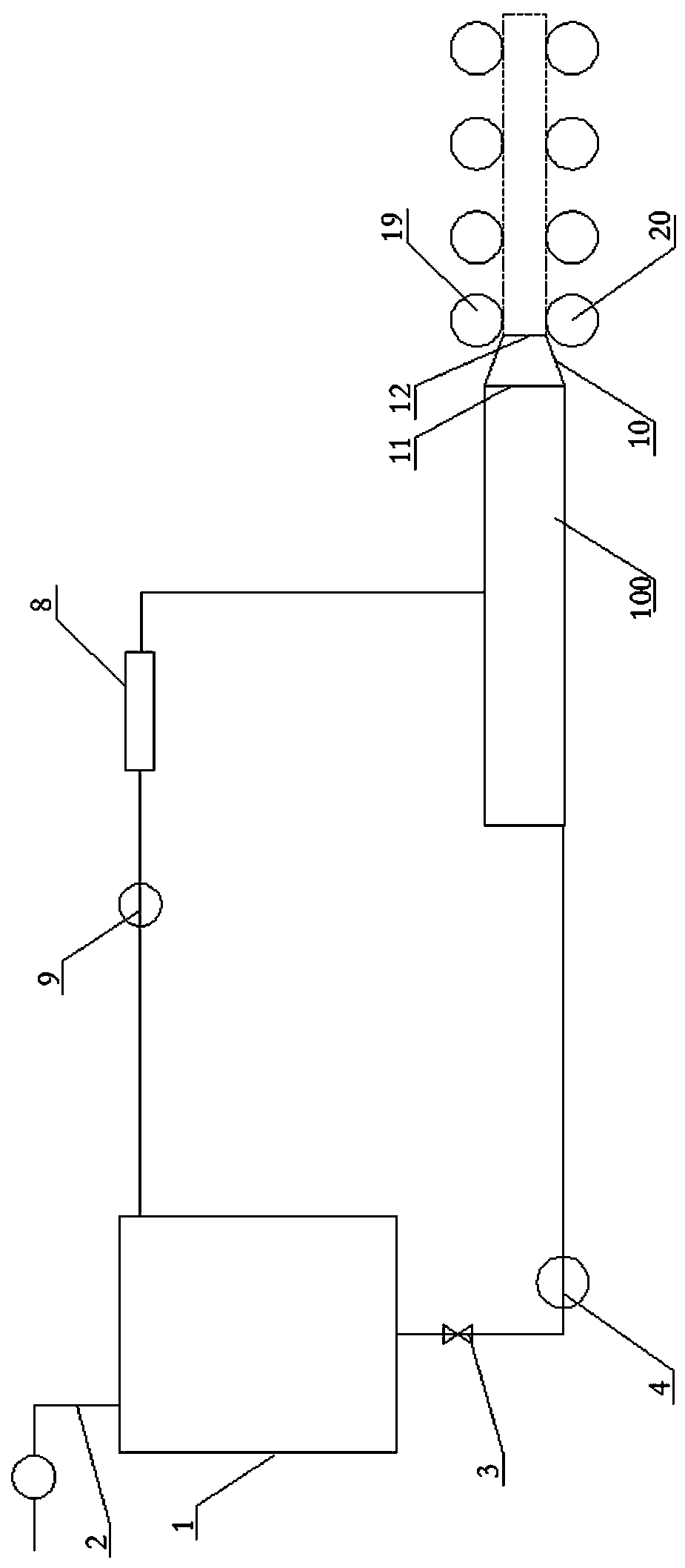

[0032] image 3 , 4 , 5: a production line for one-time reaction extrusion molding of acrylic sheet materials, including a reaction kettle 1 with an MMA feed pipe 2 and a centrifugal mixing reaction extrusion device 100, the centrifugal mixing reaction extrusion device 100 includes an extrusion Out of frame 21, front drive motor 22, outer reactor 23, inner reactor 24, rear drive motor 25, outer leveler 26, inner leveler 27, outer reactor 23 and outer leveler 26 coaxial front, The rear is set and rotatably supported in the extrusion frame 21. The outer ring gear of the outer reactor is driven by the front drive motor 22 through the gear, and the outer ring gear of the outer leveler is driven by the rear drive motor 25 through the gear. The outer reactor 23 On the inner wall of the inner wall, there are many circular arc reaction tanks 28 evenly distributed along its axial direction. The inner reactor is coaxially connected in the outer reactor and supported in the extrusion fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com