Using method for automatic feed tray

An automatic feeding tray and feed technology, which is applied in the field of farming machinery, can solve the problems of reducing feed supply and failing to increase it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

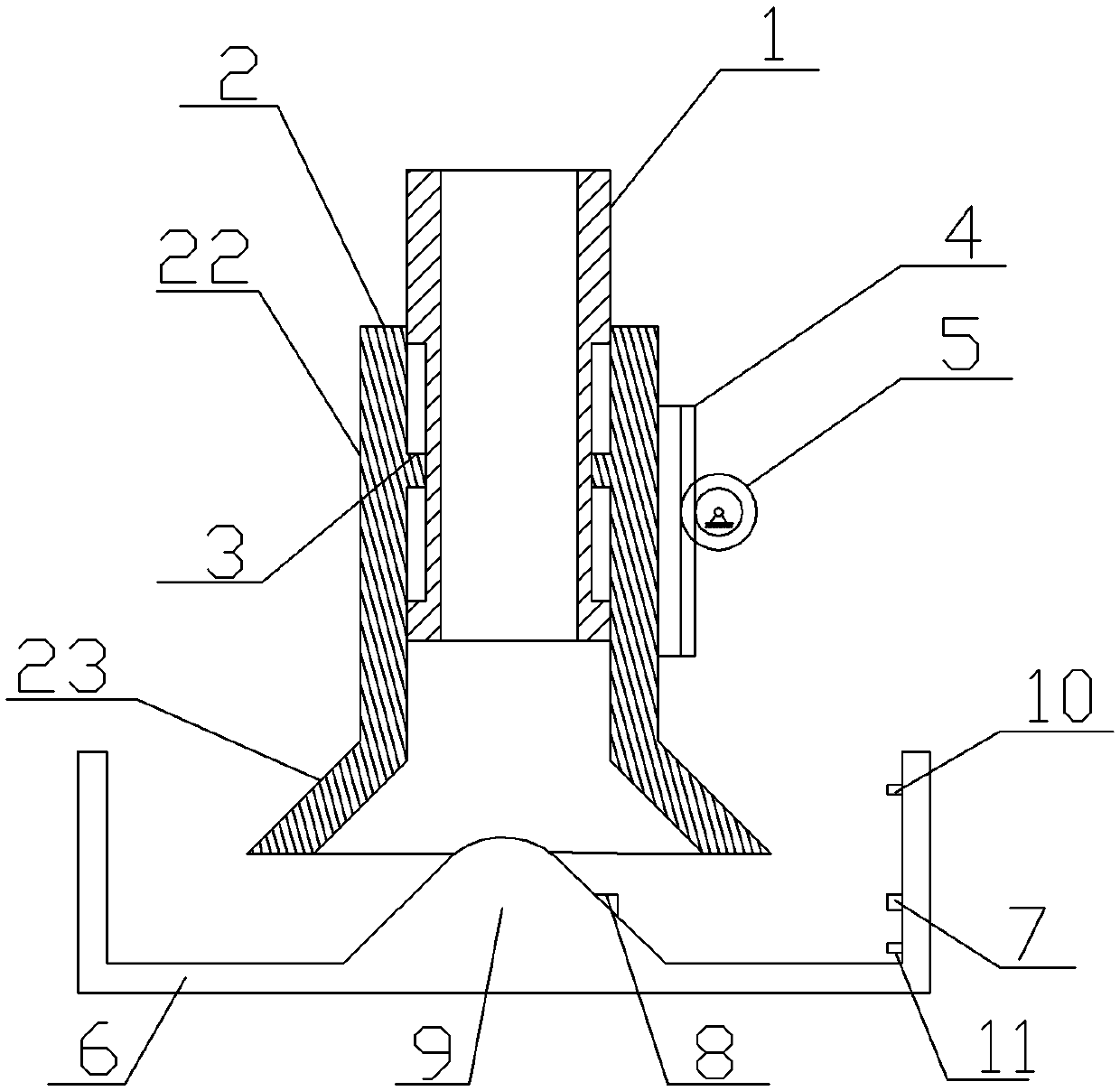

[0018] The reference signs in the accompanying drawings of the specification include: feed pipe 1, height limit cylinder 2, cone cylinder portion 21, straight cylinder portion 22, slider 3, rack 4, driving gear 5, feed trough 6, laser emitter 7 , Laser receiver 8, truncated cone 9, upper travel switch 10, lower travel switch 11.

[0019] This method uses as figure 1 As shown in the automatic feeding tray, if the automatic feeding tray is set on a frame, a screw feeder (not shown in the figure) is arranged on the frame, including a feeding pipe 1, and the upper end of the feeding pipe 1 Connected with the outlet of the screw feeder, the wall of the feed pipe 1 is provided with a vertical guide groove. The outer circle of the feed pipe 1 is covered with a height-limiting cylinder 2, which is divided into a straight cylinder part 22 and a cone cylinder part 21 from top to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com