Method for charging and emptying aluminum powder and control system thereof

A control system and aluminum powder technology, applied in the field of petrochemical equipment, can solve the problems of insufficient optimization of reaction heat removal process and equipment, poor feeding of aluminum powder, and difficulty in feeding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

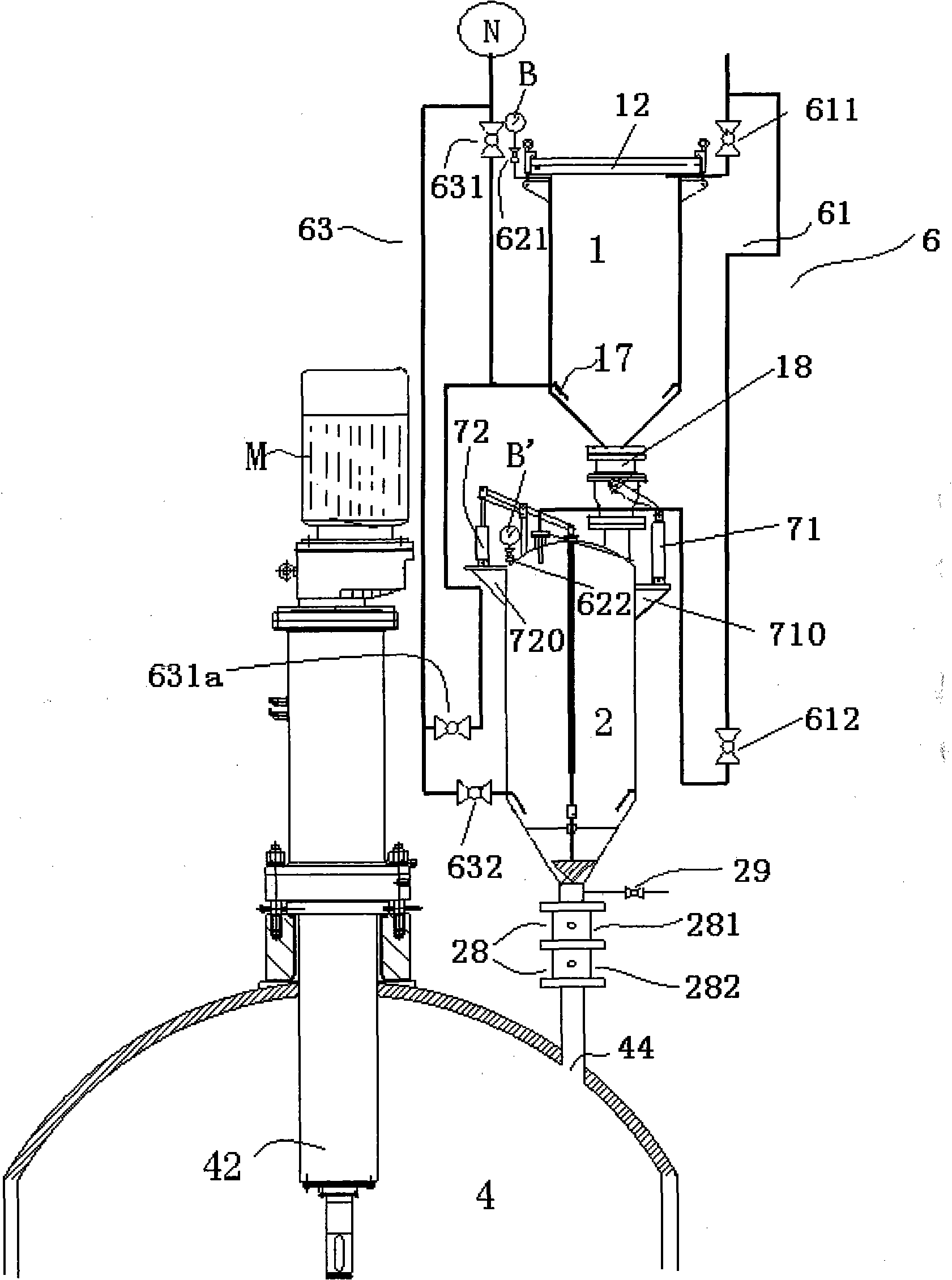

[0108] see Figure 1-6 Shown, a kind of production equipment of triethylaluminum, comprises aluminum powder feeding control system and reactor 4;

[0109] The aluminum powder feeding control system is composed of an aluminum powder feeding device and a control unit 6. The aluminum powder feeding device includes a feeding device 1 and a feeding device 2. The aluminum powder feeding control system passes through the reactor 4. Feed inlet 44 delivers aluminum powder to the reactor;

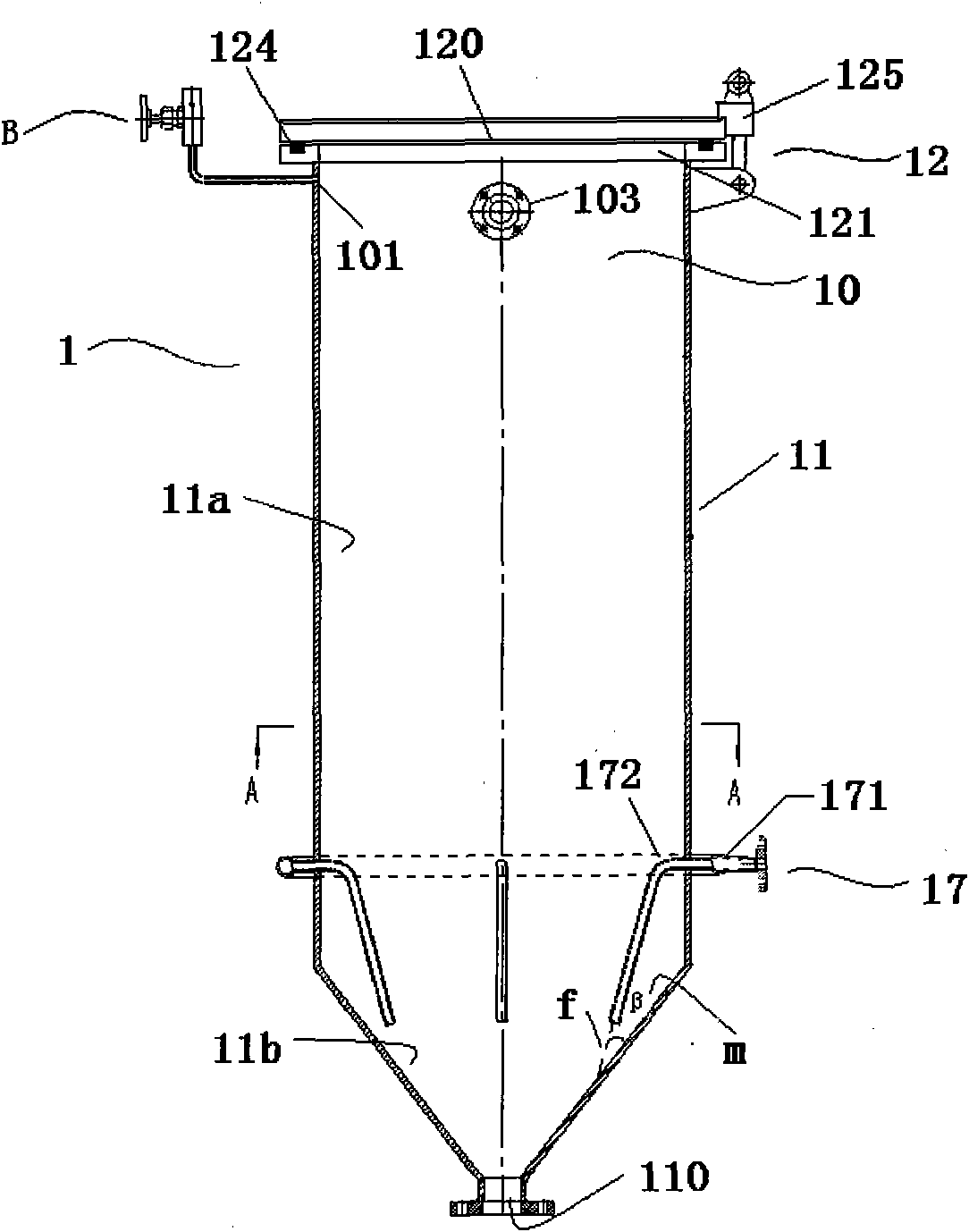

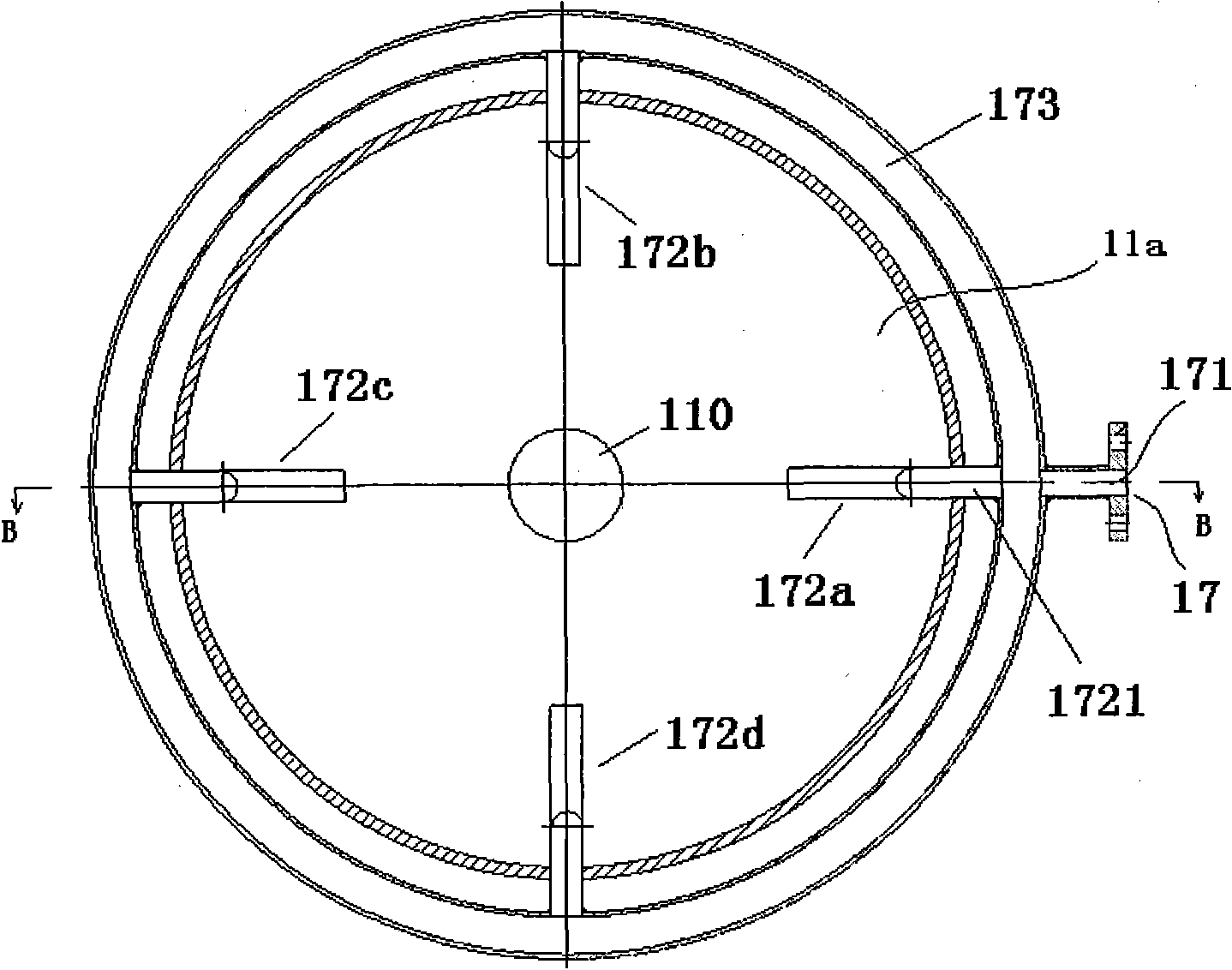

[0110] The feeding device 1 is used for nitrogen replacement of aluminum powder, see figure 2 , Figure 2a , Figure 2b As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com