Tilmicosin premix with fragrance and preparation method of tilmicosin premix

A technology of tilmicosin and premix, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc. It can solve the problem of affecting the use of tilmicosin and causing negative psychodynamic effects , Difficulty in taking animals, etc., to achieve the effect of improving drug efficacy, accelerating absorption, and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

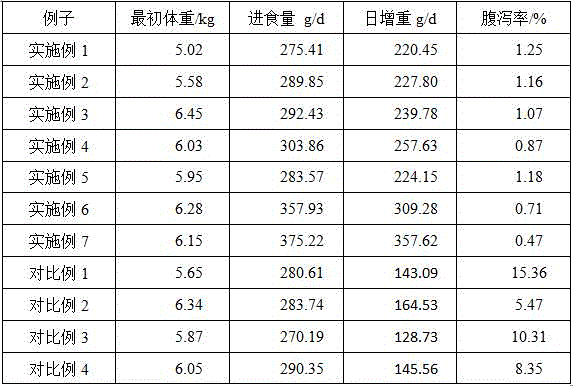

Examples

Embodiment approach

[0055] As a preferred embodiment of the present invention, the molar ratio of polyamino acid to cyclodextrin in the polyamino acid-cyclodextrin complex is 1:1-100, more preferably, the molar ratio of polyamino acid to cyclodextrin is 1 : 10-30.

[0056] As a preferred embodiment of the present invention, the polyamino acid is one or more of polyglutamic acid, polyaspartic acid, poly-L-lysine, polylysine, preferably, the The polyamino acid is polyaspartic acid.

[0057] As a preferred embodiment of the present invention, the cyclodextrin is one or more of α-cyclodextrin, β-cyclodextrin, and γ-cyclodextrin, preferably, the cyclodextrin is beta-cyclodextrin.

[0058] As a preferred embodiment of the present invention, the binder is starch slurry, polyvinyl alcohol, hydroxypropylmethylcellulose, carboxymethylcellulose, hydroxyethylcellulose, hydroxypropylcellulose, etc. One or more mixtures, preferably, the binder is hydroxypropyl methylcellulose.

[0059] As a preferred embod...

Embodiment 1

[0069] (1) In a 100mL three-necked bottle, add 0.1g of polyaspartic acid, 1-2g of β-cyclodextrin and 50mL of hexamethylphosphoric triamide, stir well at room temperature; After reacting for 15-48 hours, settling and filtering in absolute ethanol to obtain polyaspartic acid-β-cyclodextrin complex;

[0070] (2) 5% by weight of hydroxypropyl methylcellulose, 20% by weight of starch and dextrin mixture, and 15% by weight of polyaspartic acid-β-cyclodextrin complex are added to distilled water, Heat at 50-80°C to dissolve; stir evenly and cool to obtain mixture A;

[0071] (3) Add 20% by weight of tilmicosin to the solution mixture A obtained in step (1), stir for 30-40 minutes, make a soft material, granulate, dry, and sieve.

Embodiment 2

[0073] The preparation method of the polyaspartic acid-β-cyclodextrin complex is the same as in Example 1.

[0074] (1) 5% by weight of hydroxypropyl methylcellulose, 20% by weight of starch and dextrin mixture, and 20% by weight of polyaspartic acid-β-cyclodextrin complex are added to distilled water, Heat at 50-80°C to dissolve; stir evenly and cool to obtain mixture A;

[0075] (2) Add 20% by weight of tilmicosin to the solution mixture A obtained in step (1), stir for 30-40 minutes, make a soft material, granulate, dry, and sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com