Agricultural cereal spiral falling and drying device

A drying device and grain technology, which is applied in the agricultural field, can solve the problems of insufficient continuity of the drying device, unfavorable drying efficiency, and the inability to quickly disperse the grain, so as to achieve the effect of smooth falling, improving drying efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

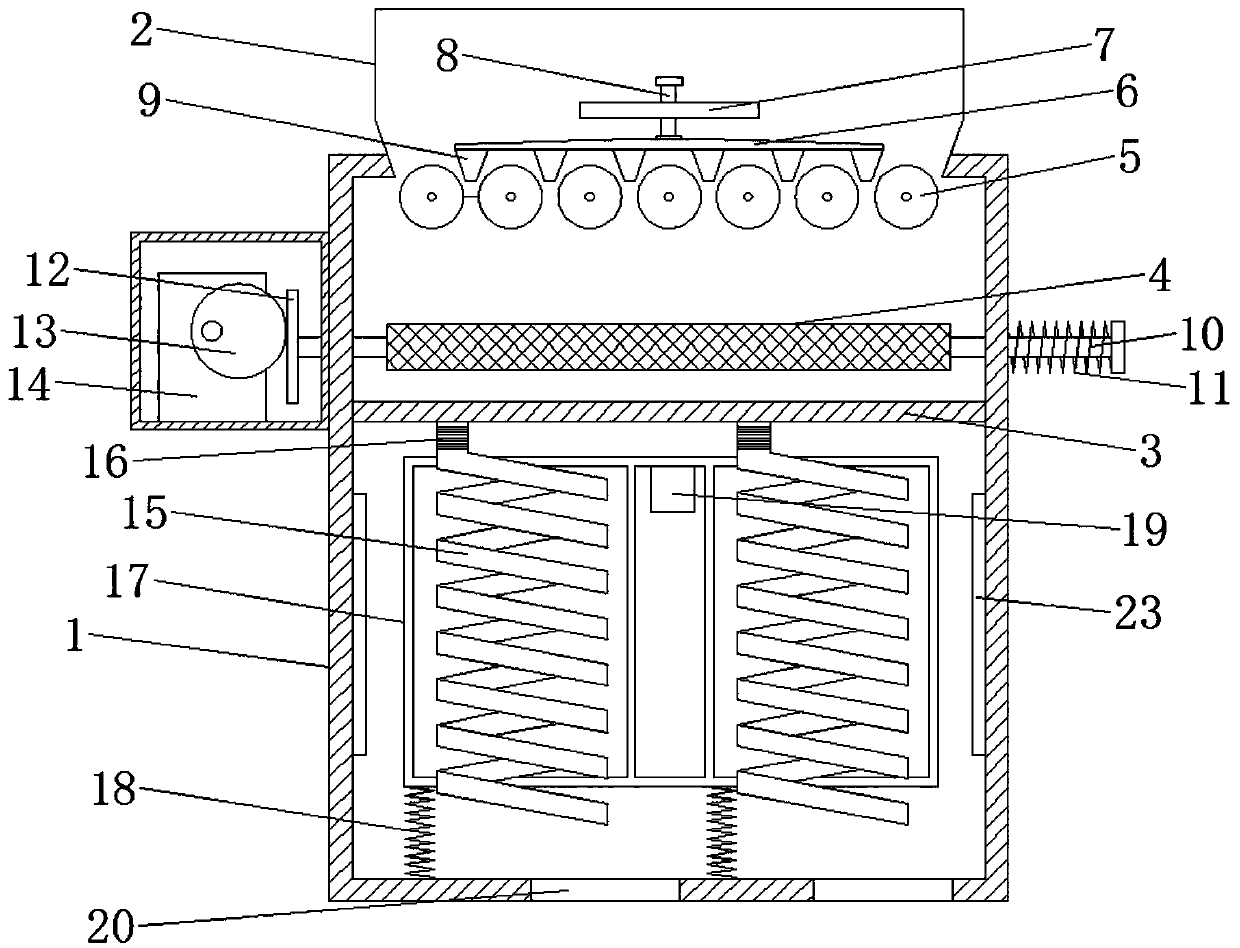

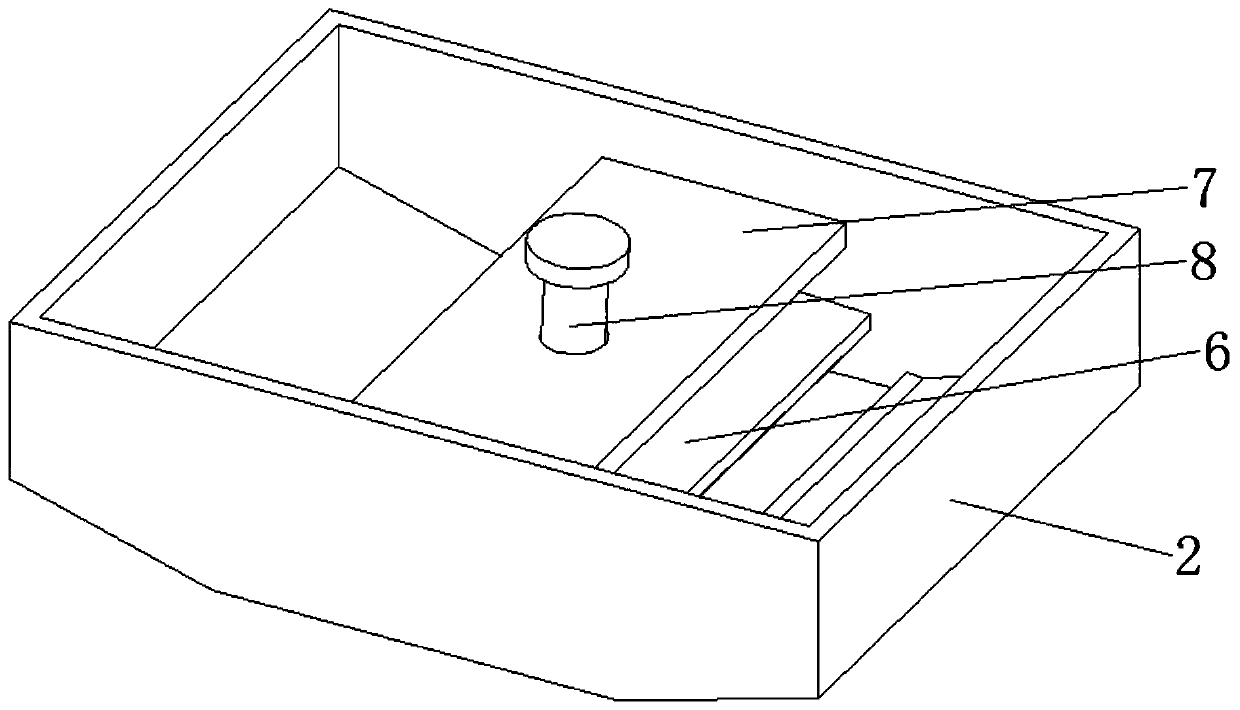

[0018] Please refer to the figure, in the embodiment of the present invention, an agricultural grain spiral falling drying device includes a housing 1, a feed hopper 2, a partition 3 and a hot air pipe 23; the feed hopper 2 is fixedly installed on the housing 1, and communicates with the housing 1, and feeds the incoming grain into the housing 1; the partition 3 is horizontally fixed in the housing 1, and divides the housing 1 into upper and lower parts.

[0019] The connection between the bottom of the feed hopper 2 and the housing 1 is evenly and equidistantly provided with several horizontal retaining rollers 5, and the retaining rollers 5 rotate around the central axis, so that the grains falling from above can pass through the adjacent retaining rollers 5. The gap between them falls to avoid falling more grains at one time; a horizontal liftable baffle 6 is arranged in the feed hopper 2, and the baffle 6 is located above the bottom of the feed hopper 2, and the baffle 6 T...

Embodiment 2

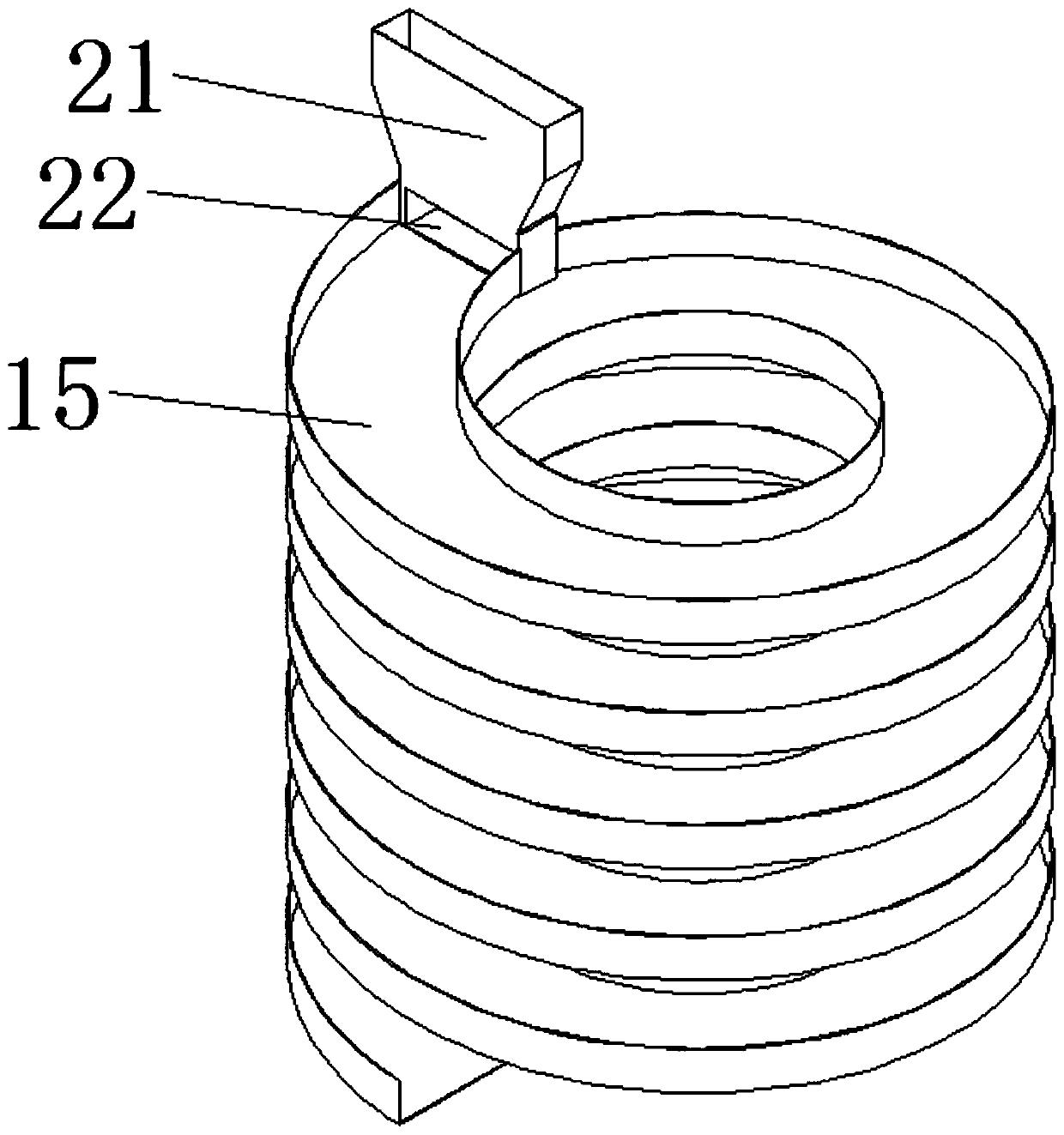

[0023] On the basis of Embodiment 1, a plurality of spiral flow channels 15 are fixedly connected to the same support frame 17, and a plurality of support springs 18 are fixed between the bottom of the support frame 17 and the bottom of the housing 1, and are supported by the support springs 18. Bracing frame 17, vibrating motor 19 is installed on bracing frame 17, drives whole shell supporting frame 17 to shake after vibrating motor 19 starts, is convenient to the whereabouts of the grain in the spiral flow channel 15, improves the fluidity of grain on the spiral flow channel 15.

[0024] When in use, the grain is fed through the feed hopper 2, and under the action of the retaining roller 5 and the retaining block 9, the grain falls between the adjacent retaining rollers 5 to control the feeding speed, and the retaining block 9 can Change the size of the gap to facilitate control and adjustment; the falling grains are dispersed through the horizontal reciprocating deceleration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com