Powdery material spraying pump

A technology of powder materials and jet pump, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of legacy materials, harsh working environment, affecting the use efficiency, etc., to achieve low system cost and operating cost, and improve Material conveying capacity, the effect of improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

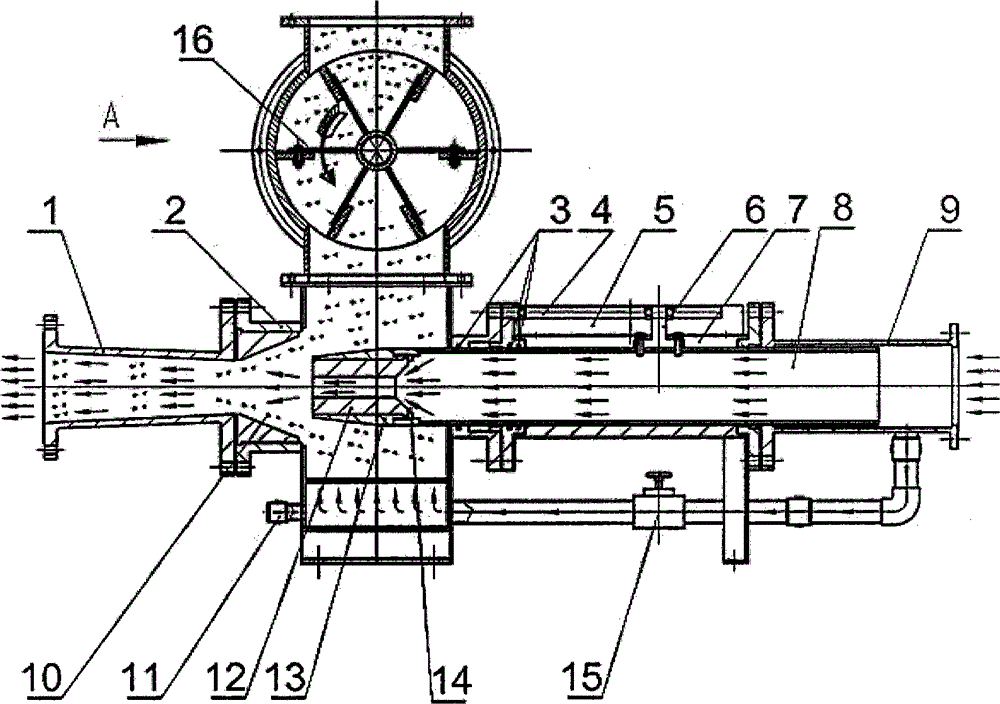

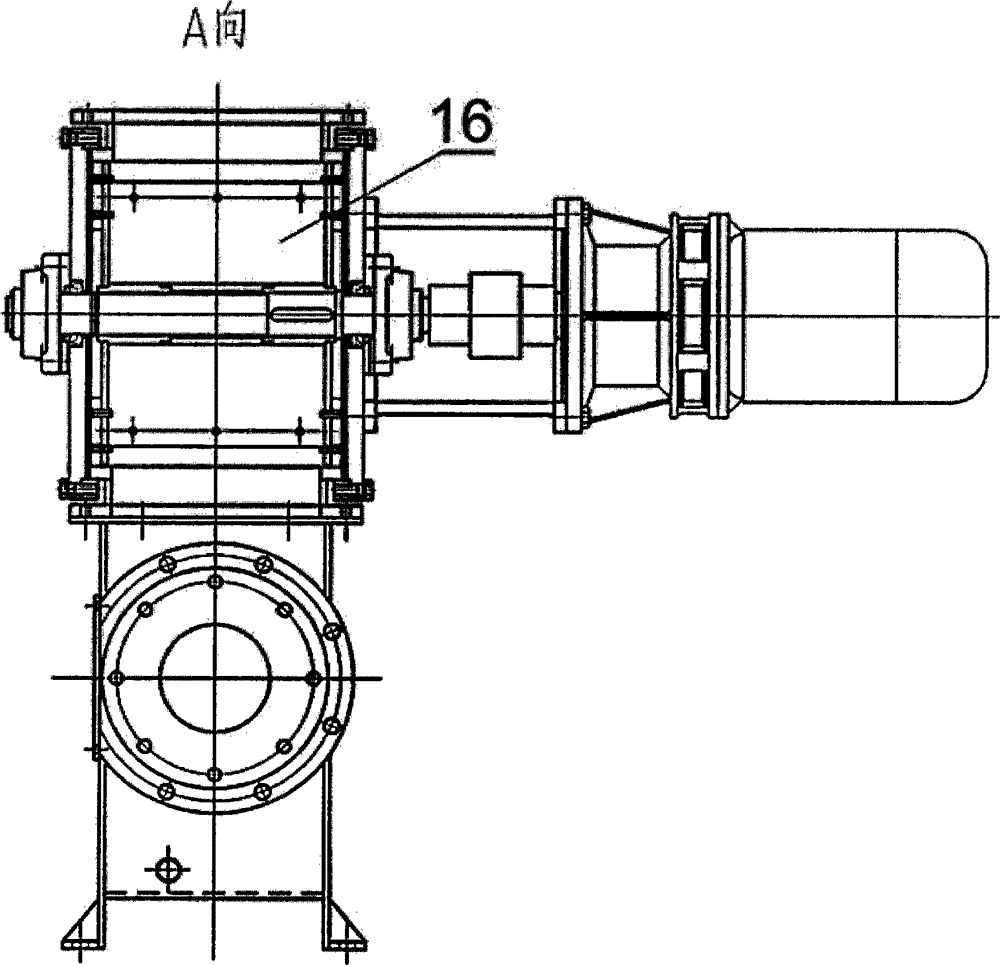

[0021] Such as figure 1 and figure 2 Shown, a kind of powdery material injection pump, it comprises air inlet pipe 9, hollow pipe 8, pump body 2, air locker 16, regulating valve 15, and the output port of described air inlet pipe 9 is communicated with hollow pipe 8, so One end of the hollow tube 8 is connected to the intake pipe 9, the other end of the hollow tube 8 is connected to the nozzle 12, the hollow tube 8 is fixedly provided with a slide iron 6, and one end of the slide iron 6 is fixedly arranged on the On the hollow tube 8, the other end of the sliding iron 6 is sleeved on the screw mandrel 4, and the sliding iron 6 and the screw mandrel 4 are screwed in connection; the described nozzle 12 extends into the inside of the pump body 2 , the air locker 16 is arranged above the pump body 2, one side of the pump body 2 is connected with the nozzle 12, the hollow pipe 8, and the intake pipe 9 in sequence, and the other side of the pump body 2 is connected with The conic...

Embodiment 2

[0026] Such as figure 1 and figure 2 Shown, a kind of powdery material injection pump, it comprises air inlet pipe 9, hollow pipe 8, pump body 2, air locker 16, regulating valve 15, and the output port of described air inlet pipe 9 is communicated with hollow pipe 8, so One end of the hollow tube 8 is connected to the intake pipe 9, the other end of the hollow tube 8 is connected to the nozzle 12, the hollow tube 8 is fixedly provided with a slide iron 6, and one end of the slide iron 6 is fixedly arranged on the On the hollow tube 8, the other end of the sliding iron 6 is sleeved on the screw mandrel 4, and the sliding iron 6 and the screw mandrel 4 are screwed in connection; the described nozzle 12 extends into the inside of the pump body 2 , the air locker 16 is arranged above the pump body 2, one side of the pump body 2 is connected with the nozzle 12, the hollow pipe 8, and the intake pipe 9 in sequence, and the other side of the pump body 2 is connected with The conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com