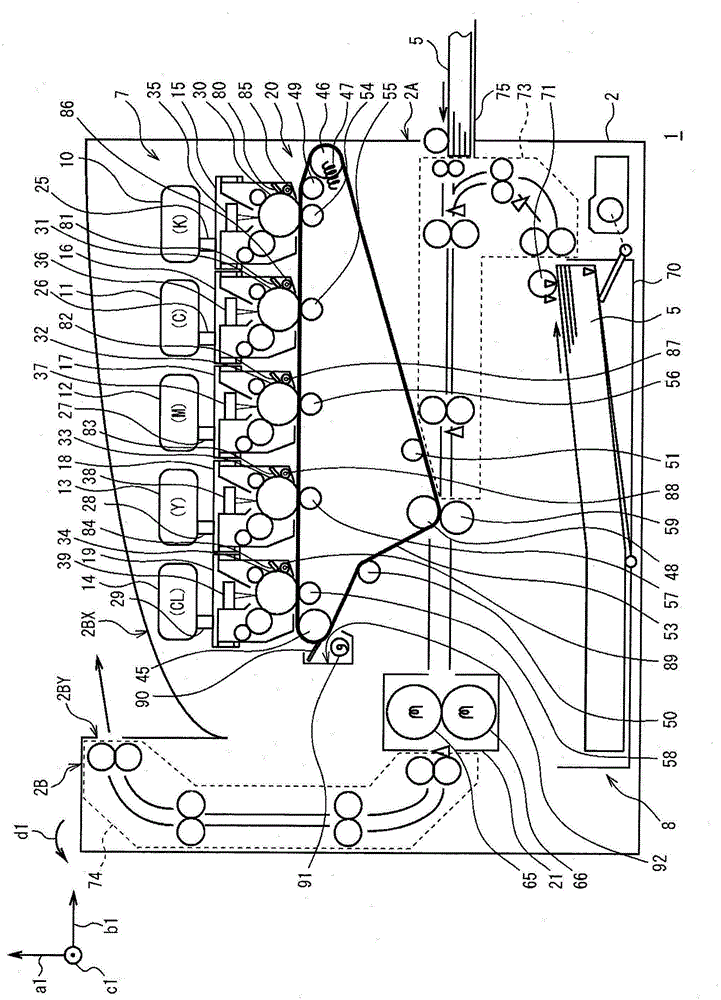

Developer conveying device and image forming apparatus

A technology for conveying device and developer, applied in the direction of electric recording process using charge pattern, equipment for electric recording process using charge pattern, electrography, etc., can solve the problems such as the reduction of toner conveying capacity, and achieve the prevention of conveying The effect of capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

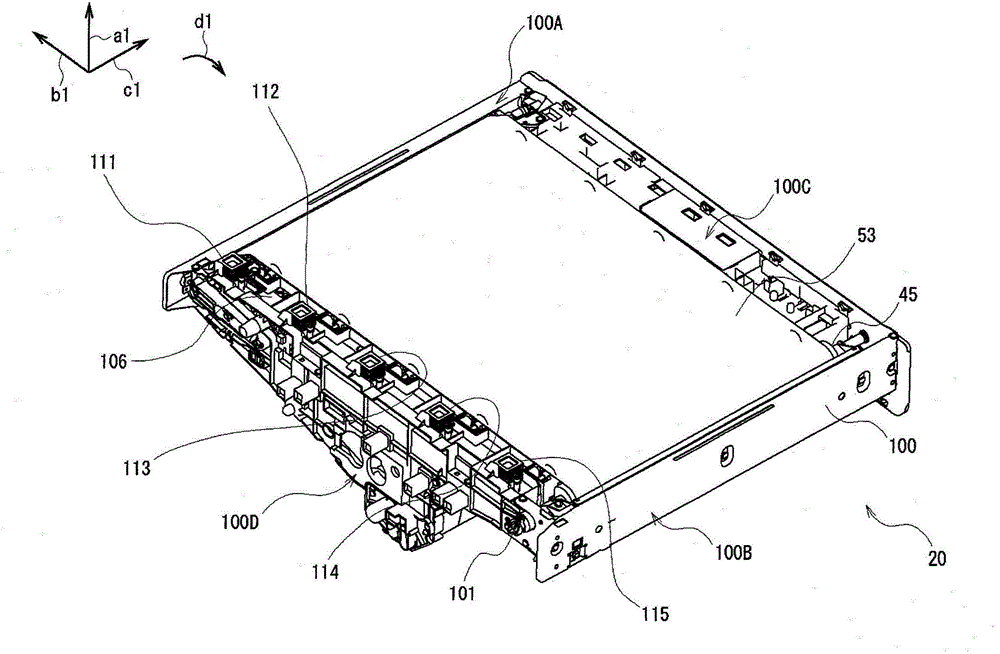

Examples

Embodiment approach 2

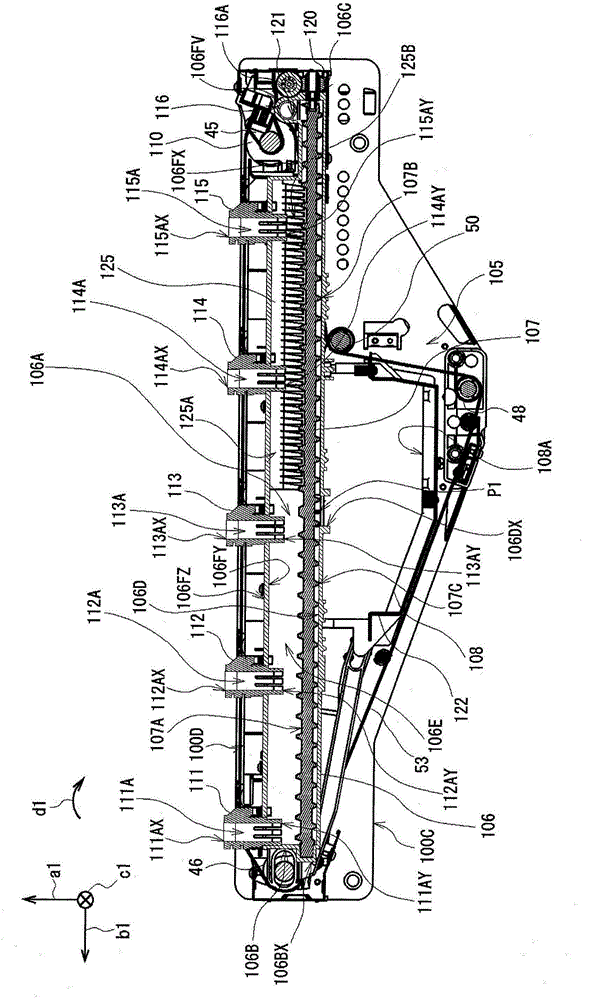

[0102] In addition, in the above-mentioned embodiment, the case where the plurality of toner removing fins 125B are formed in a flat plate shape in the toner removing portion 125 has been described, but the present invention is not limited thereto. Figure 13 As shown in (A), in the toner removing portion 133, the front ends of the plurality of toner removing fins 133A may be curved in an arc shape, and the back surface of the front ends may be pressed against the toner transport body 107. on the surface of the shaft portion 107A. and, if Figure 13 As shown in (B), in the toner removing portion 134 , the front ends of the plurality of toner removing fins 134A may be bent at a predetermined angle, and the front ends may be pressed against the shaft portion 107A of the toner conveying body 107 . on the surface.

[0103] In the present invention, with these configurations, as in the case of the above-mentioned embodiment, the tip ends of the plurality of toner removing fins 13...

Embodiment approach 3

[0105] Furthermore, in the above-mentioned embodiment, a case has been described in which the toner removing portion is provided in the range from the front of the concave portion 106FX to the vicinity immediately above the toner discharge port 106DX in the toner recovery conveyance path 106A. 125, but it is not limited thereto. For example, it is also possible to lower the arrangement position of the transport path forming part 106 in the right side frame 100D so that it does not interfere with the bearing part 110 for the drive roller 45, so that the transport path forming part 106 The height of the internal space (that is, the height of the toner recovery conveyance path 106A) is uniform from the front end to the rear end, and the toner removing unit 125 is provided in the entire first conveyance range.

[0106] In addition, the present invention may be configured such that not only the toner removing unit 125 is provided in the toner recovery conveyance path 106A, but also ...

Embodiment approach 5

[0112] Furthermore, in the above-mentioned embodiments, it has been described that the image forming apparatus of the present invention is applied to Figure 1 to Figure 13 The color printer 1 described above is not limited thereto, and can be widely applied to image forming apparatuses of various configurations such as monochrome electrophotographic printers, multifunction printers, facsimile machines, multifunction machines, copiers, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com