Corn crankshaft threshing machine

A threshing machine and crankshaft technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as machine jamming and incomplete corn threshing, and achieve the effect of easy promotion and application and strong structural continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

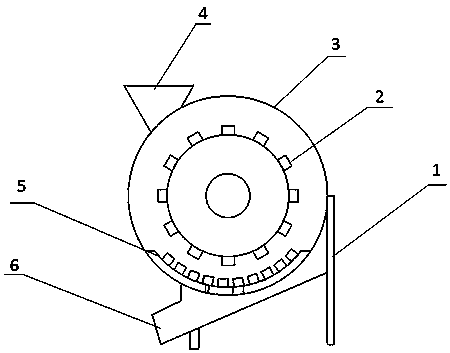

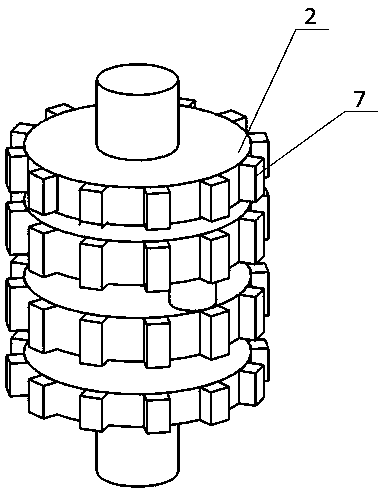

[0018] Such as Figure 1-2 As shown, a corn crankshaft threshing machine includes a frame 1, an off-line bin 3 is arranged on the frame 1, and a threshing roller is arranged in the threshing bin 3; a material inlet 4 and a discharge port at the bottom are arranged outside the threshing bin 3 7; the described threshing roller is a crankshaft threshing roller 2, and the outside of the crank of the crankshaft threshing roller 2 is provided with a threshing tooth 7; below the crankshaft threshing roller 2, a threshing arc 5 corresponding to the crankcase is provided; the described The number of the cranks of the threshing crank roller 2 matches the feed opening 4 and the discharge opening. There are at least five threshing teeth on each crank.

[0019] When in use: Put the corn into the material inlet 4 of the corresponding crank, and the corn will be threshed quickly through the threshing teeth 7 on the threshing roller 2 of the crankshaft and the threshing arc 5 at the bottom, ...

Embodiment 2

[0021] Such as Figure 1-2 As shown, a corn crankshaft threshing machine includes a frame 1, an off-line bin 3 is arranged on the frame 1, and a threshing roller is arranged in the threshing bin 3; a material inlet 4 and a discharge port at the bottom are arranged outside the threshing bin 3 7; the described threshing roller is a crankshaft threshing roller 2, and the outside of the crank of the crankshaft threshing roller 2 is provided with a threshing tooth 7; below the crankshaft threshing roller 2, a threshing arc 5 corresponding to the crankcase is provided; the described The number of the cranks of the threshing crank roller 2 matches the feed opening 4 and the discharge opening. Each crank is provided with six threshing teeth.

[0022] The working principle is consistent with that of Example 1.

Embodiment 3

[0024] Such as Figure 1-2 As shown, a corn crankshaft threshing machine includes a frame 1, an off-line bin 3 is arranged on the frame 1, and a threshing roller is arranged in the threshing bin 3; a material inlet 4 and a discharge port at the bottom are arranged outside the threshing bin 3 7; the described threshing roller is a crankshaft threshing roller 2, and the outside of the crank of the crankshaft threshing roller 2 is provided with a threshing tooth 7; below the crankshaft threshing roller 2, a threshing arc 5 corresponding to the crankcase is provided; the described The number of the cranks of the threshing crank roller 2 matches the feed opening 4 and the discharge opening. There are at least five threshing teeth on each crank.

[0025] The crankshaft threshing roller can be placed vertically to achieve the threshing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com