Corn threshing method

A corn threshing and corn technology, which is applied in threshing equipment, metal processing, agricultural machinery and implements, etc., can solve the problems of many corn residues, easy to damage the integrity of corn kernels, and large corn friction, so as to achieve convenient threshing and reduce threshing Fragmentation rate, the effect of reducing mutual support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Corn threshing method, comprises the following steps:

[0026] a. material selection, select corn with neatly arranged corn kernels;

[0027] b. cutting for the first time, cutting off the upper and lower parts of the corn, taking the cut corn cob 27, and threshing the cut corn upper part and the lower part of the corn separately;

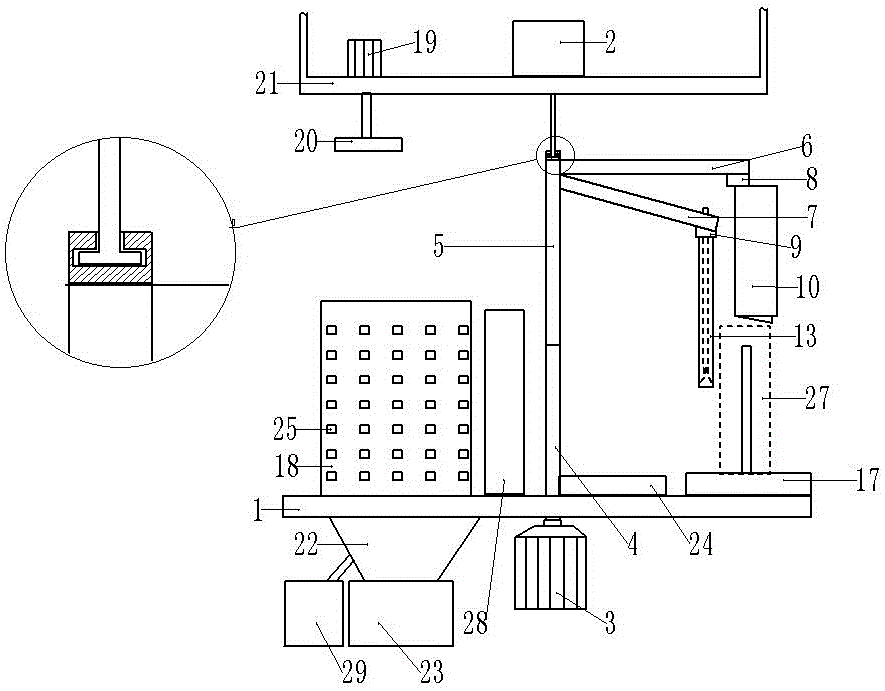

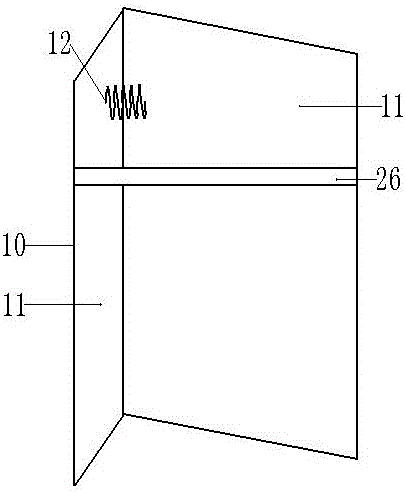

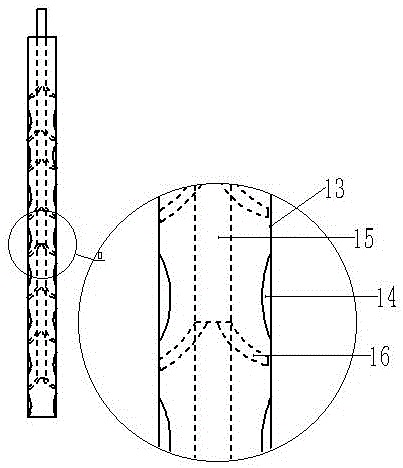

[0028] c. Set the cutting device, such as figure 1 As shown, including the workbench 1, the top of the workbench 1 is provided with a suspension 21, the suspension 21 is provided with a cylinder 2 and a second reduction motor 19, the cylinder 2 includes a piston rod, and the bottom of the workbench 1 is provided with a first reduction motor 3 , the upper end of the workbench 1 is rotatably connected to a spline shaft 4, the spline shaft 4 is connected to the first reduction motor 3, the lower end of the spline shaft 4 is welded with a scraper 24, the upper part of the spline shaft 4 is keyed to a shaft sleeve 5, and the shaft The sleeve 5 ...

Embodiment 2

[0034] The difference between this example and Example 1 is that the drying temperature of the small corn sticks is 45° C., and the drying time is 13 minutes; the drying temperature of the large corn sticks is 55° C., and the drying time is 15 minutes.

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that: the drying temperature of the small corn sticks is 50° C., and the drying time is 15 minutes; the drying temperature of the large corn sticks is 60° C., and the drying time is 18 minutes.

[0037] The corn kernels removed by the method of the invention can maintain more than 90% integrity, have a relatively complete shape, and the processing efficiency of the corn is also improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com