Thrashing drum

A technology for threshing drums and threshing parts, which is applied in threshing equipment, applications, agricultural machinery and implements, etc. It can solve the problems of low grain threshing efficiency, cumbersome disassembly, and large driving load, so as to maximize threshing efficiency, improve threshing efficiency, Meticulous effect of the threshing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

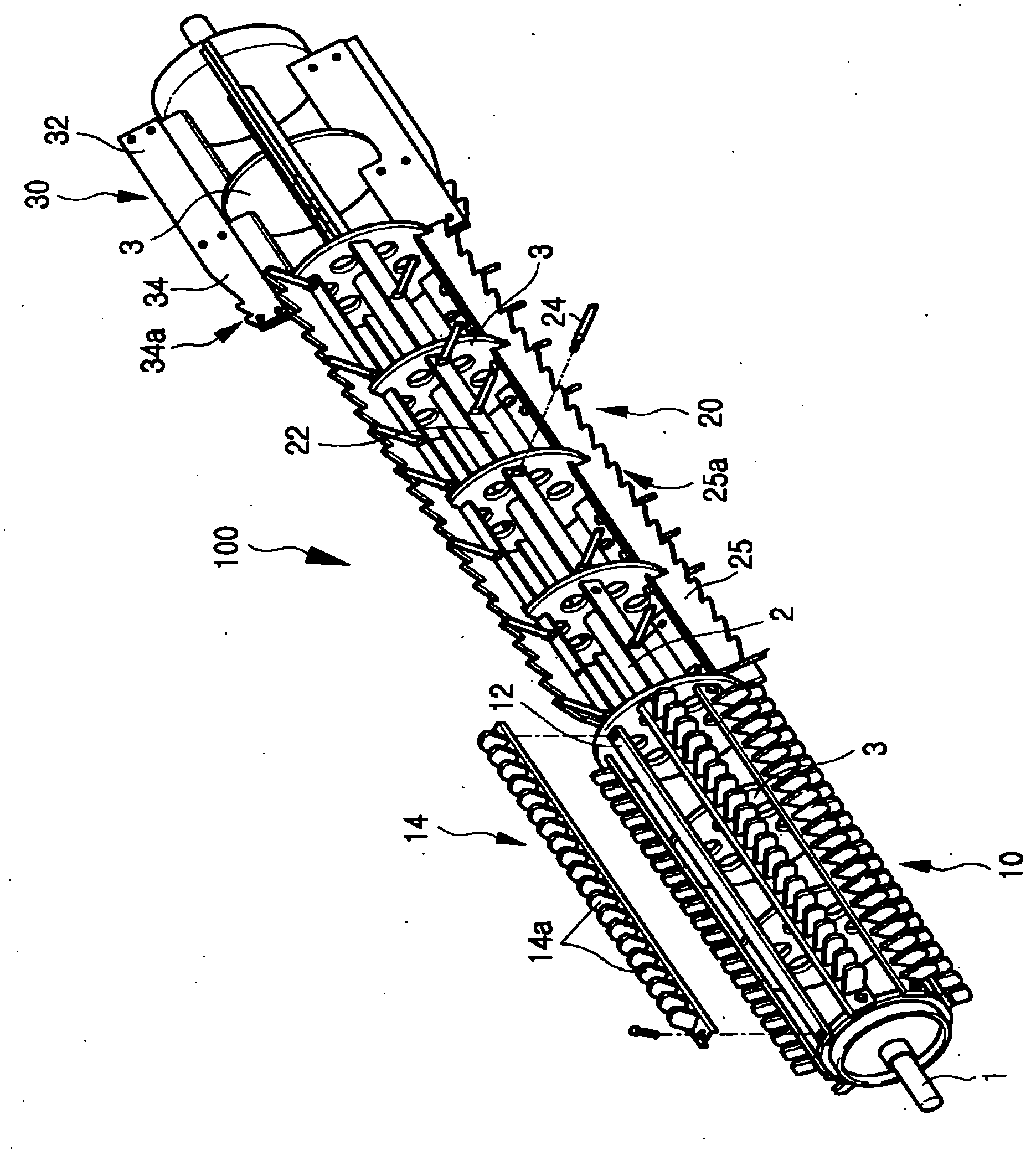

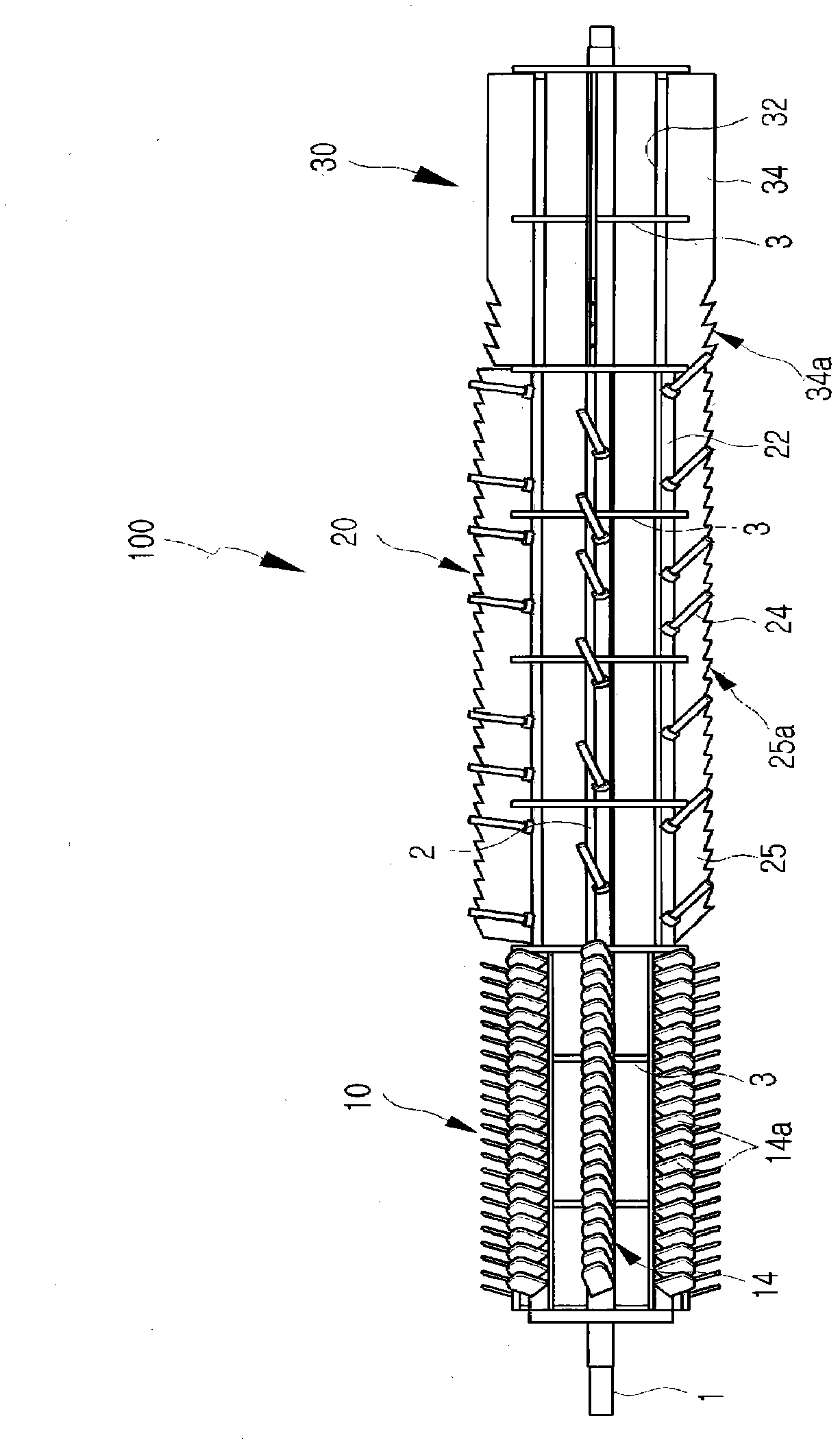

[0032] Hereinafter, preferred embodiments of the threshing cylinder according to the present invention will be described in detail with reference to the accompanying drawings.

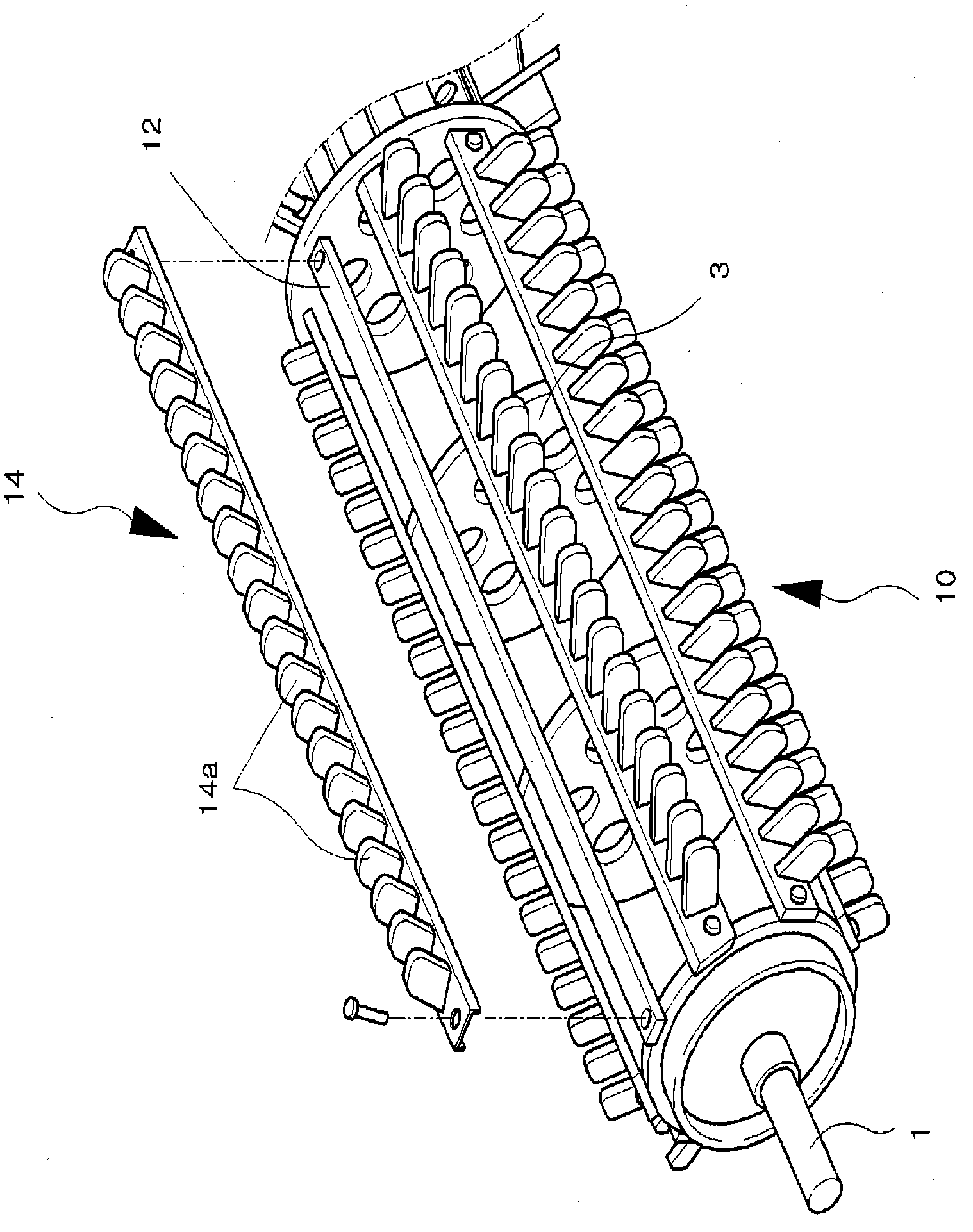

[0033] figure 2 is a perspective view schematically showing a main part of a threshing drum according to an embodiment of the present invention, image 3 It is a main part front view which schematically shows the threshing drum which concerns on one Embodiment of this invention.

[0034] Such as figure 2 and image 3 As shown, the threshing cylinder according to an embodiment of the present invention includes: a shaft rod 2 , a plurality of support plates 3 , a primary threshing part 10 , a secondary threshing part 20 , and a discharge part 30 .

[0035] Although not shown, a threshing drum according to an embodiment of the invention is installed on a conventional threshing machine for threshing grain.

[0036] Mounting shafts 1 for receiving rotational force are formed on both sides of the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com