Plot seed threshing machine

A thresher and seed technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of complex and time-consuming cleaning, failure to ensure that varieties are not mixed, and grains cannot be sieved by concave plates in time, etc., to achieve a crushing rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

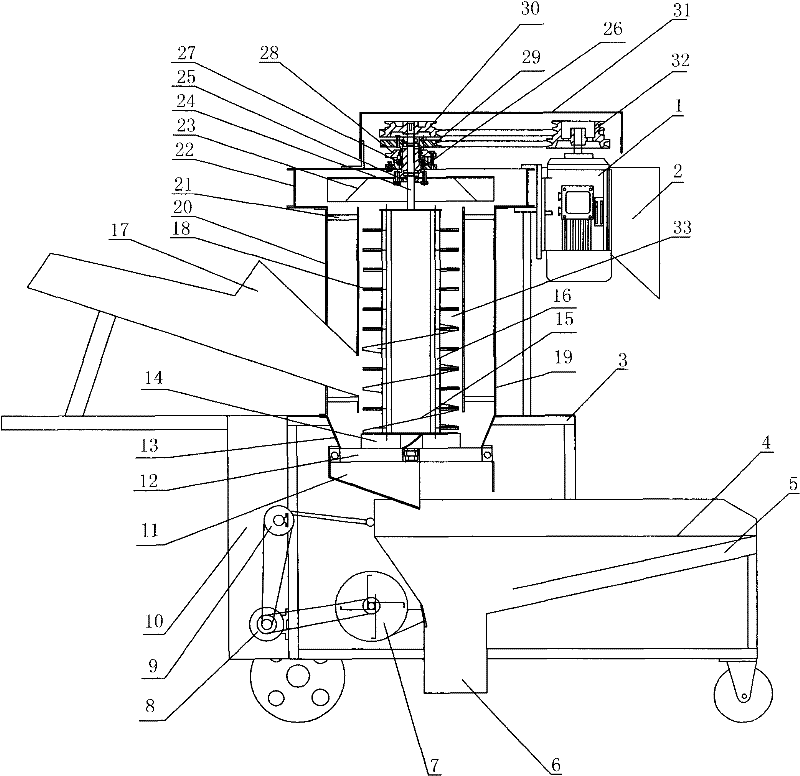

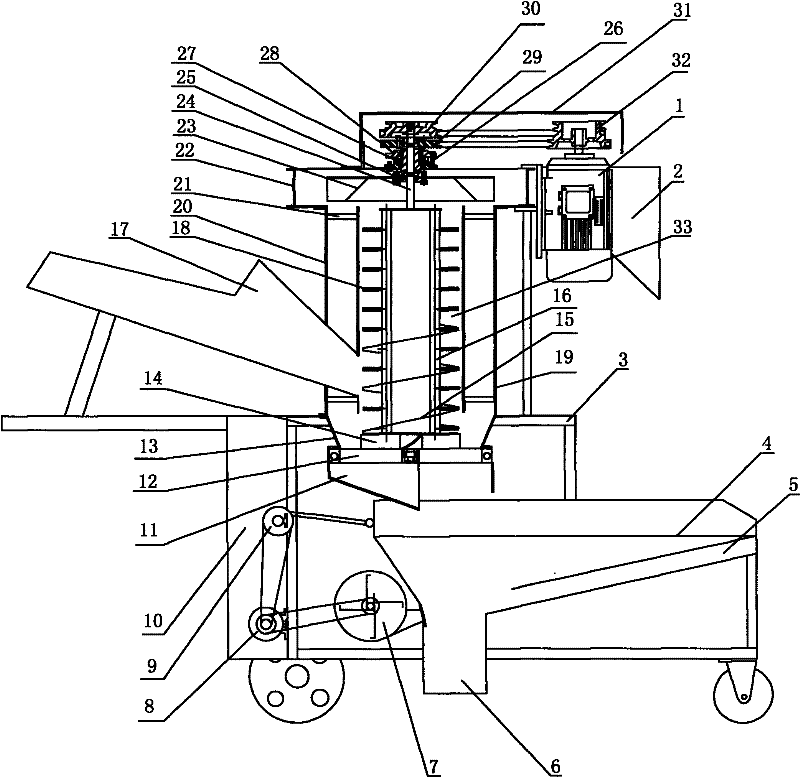

[0037] Such as figure 1 As shown, the present invention discloses a small area seed thresher, comprising a feeding port 17, a threshing chamber 33 arranged in the drum casing 20, and a cleaning system. A cylindrical concave plate 19 is vertically arranged in the threshing chamber 33, The circular punching holes for separating grains are distributed on the concave plate 19; a rotatable main shaft 24 is erected in the center of the threshing chamber 33, and a threshing tooth 18 is arranged on the upper part of the main shaft 24, and a threshing tooth 18 is arranged on the lower part of the main shaft 24. A helical blade 15 is provided, a high-speed rotatable miscellaneous suction fan 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com