A corn grain combine harvester under high moisture content

A combine harvester, high moisture content technology, used in harvesters, threshing equipment, agricultural machinery and implements, etc., can solve problems such as grain damage, scratches, extrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

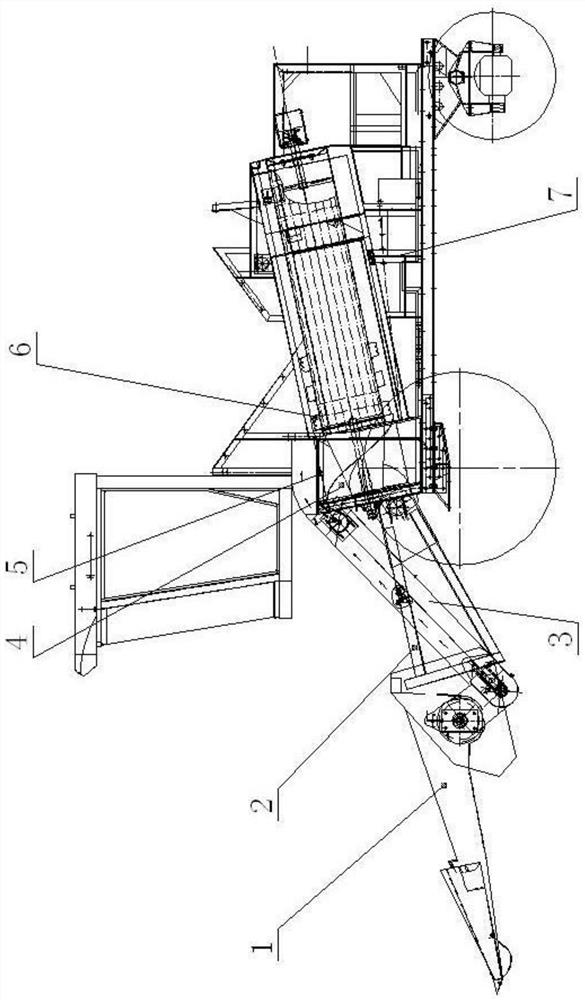

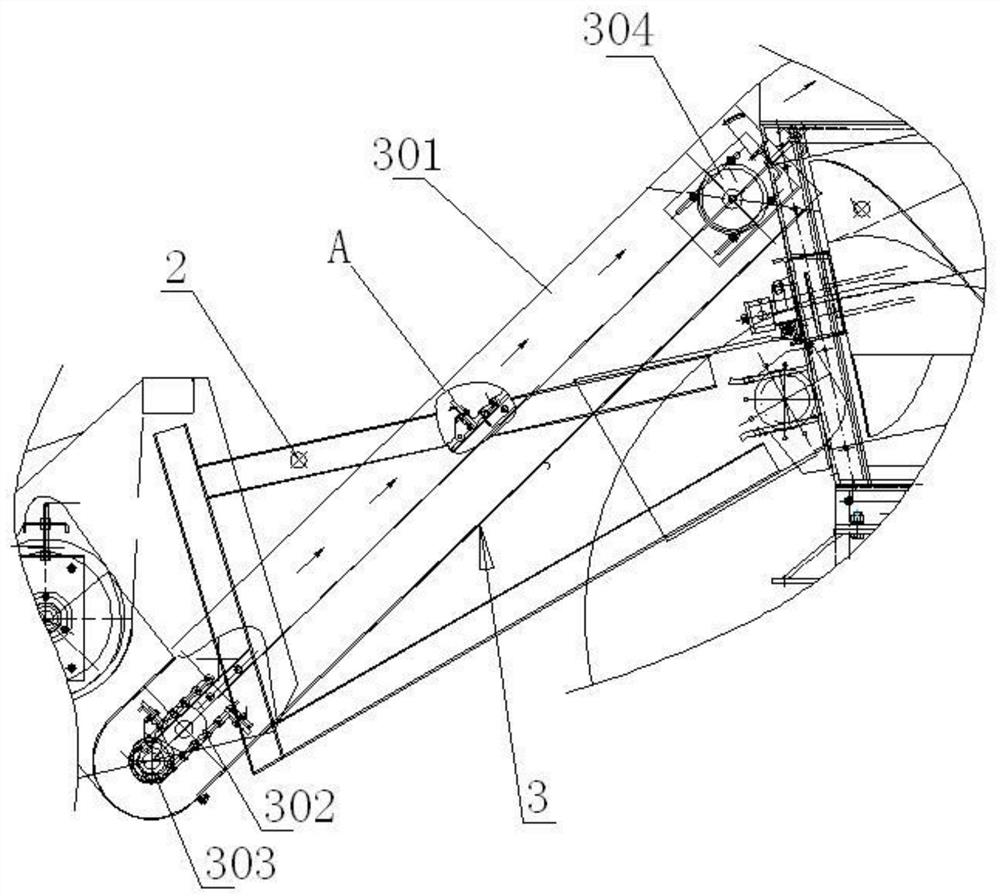

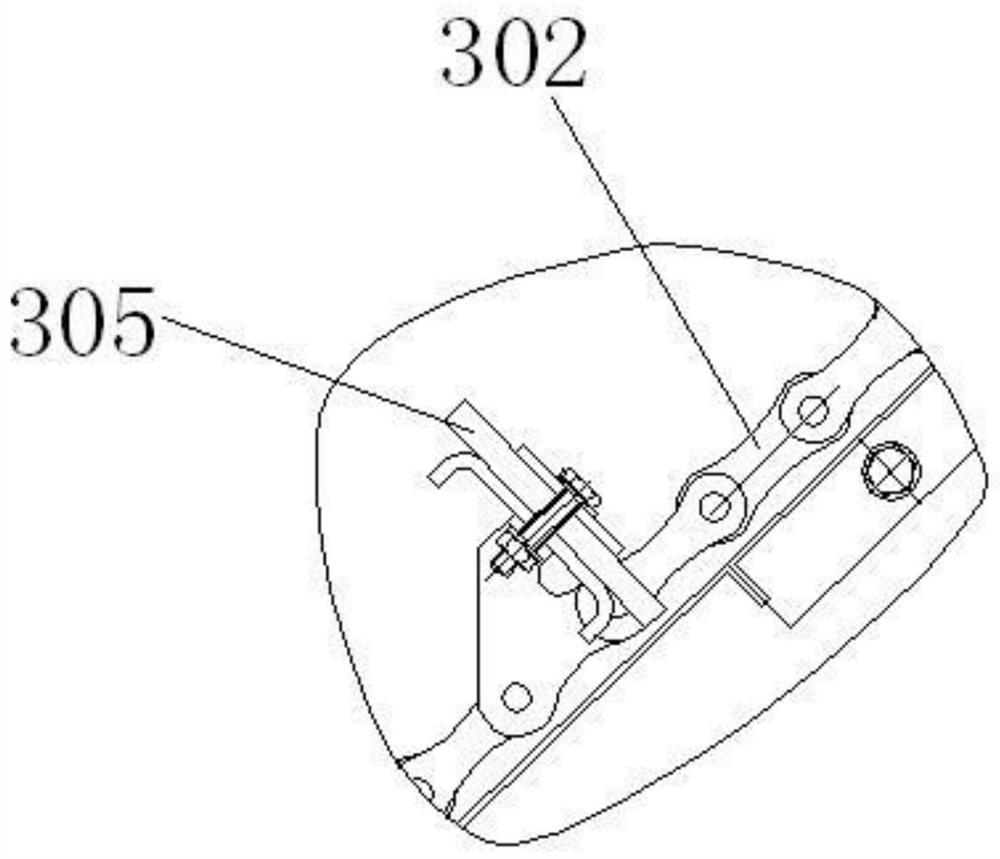

[0027]As shown in the accompanying drawings, a corn grain combine harvester with high moisture content includes a header 1, an elevator 3, a feeding cylinder 5, a plate-type axial flow threshing drum 6, and a threshing concave plate 8. Described cutting platform 1 is prior art, can harvest corn ear, and header is provided with auger and can convey the corn ear that picks off, and for example: publication number is 109392436A, and name is a kind of China of corn harvester harvesting platform Invention patent application. The header 1 is fixed on one end of the support arm 2, and the other end of the support arm 1 is fixed on the frame 7 of the harvester. The support arm 1 is a support welded by section steel. The elevator 3 is a conveyor chain structure, and the conveyor chain 302 of the elevator 3 is connected with a plurality of ear scrapers 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com