Self-pressure relief bolt

A technology of self-relieving pressure and bolts, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of not using pressure relief protection devices, and achieve the effect of reducing direct collision and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

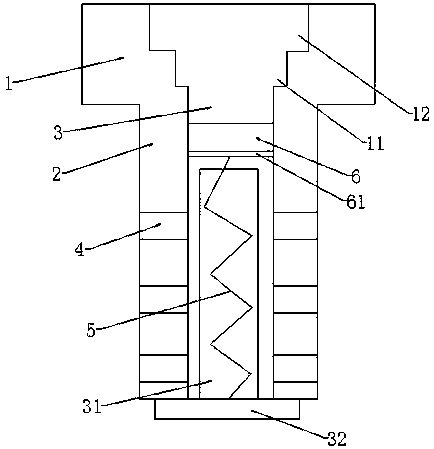

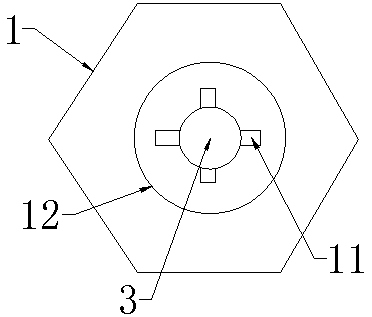

[0022] Such as Figure 1-2 As shown: this embodiment is a self-relieving bolt, including a bolt head 1 and a screw rod 2, a screwdriver groove 11 is provided at the upper center of the bolt head 1, threads are formed on the outer ring surface of the screw rod 2, and the screw rod 2 is arranged on At the center of the lower part of the bolt head 1, a pressure relief channel 3 is provided at the central position of the bolt head 1 and the screw rod 2 along the vertical axis, and six corresponding pressure relief ports 4 are arranged on the screw rod 2 from top to bottom. 3. A guide pipe 31 is provided, and the lower end of the guide pipe 31 is welded with a fixed plate 32, the fixed plate 32 is welded and fixed to the bottom of the screw rod 2, a spring 5 is arranged in the guide pipe 31, and one end of the spring 5 is connected with the fixed plate 32,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com