A kind of fiber cage for loose fiber dyeing machine

A dyeing machine and fiber cage technology, applied in the direction of processing textile material carriers, etc., can solve the problems of easy extrusion damage to the cylinder, damage to the dye vat, bumps, etc., to achieve convenient maintenance and repair, reduce direct collisions, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

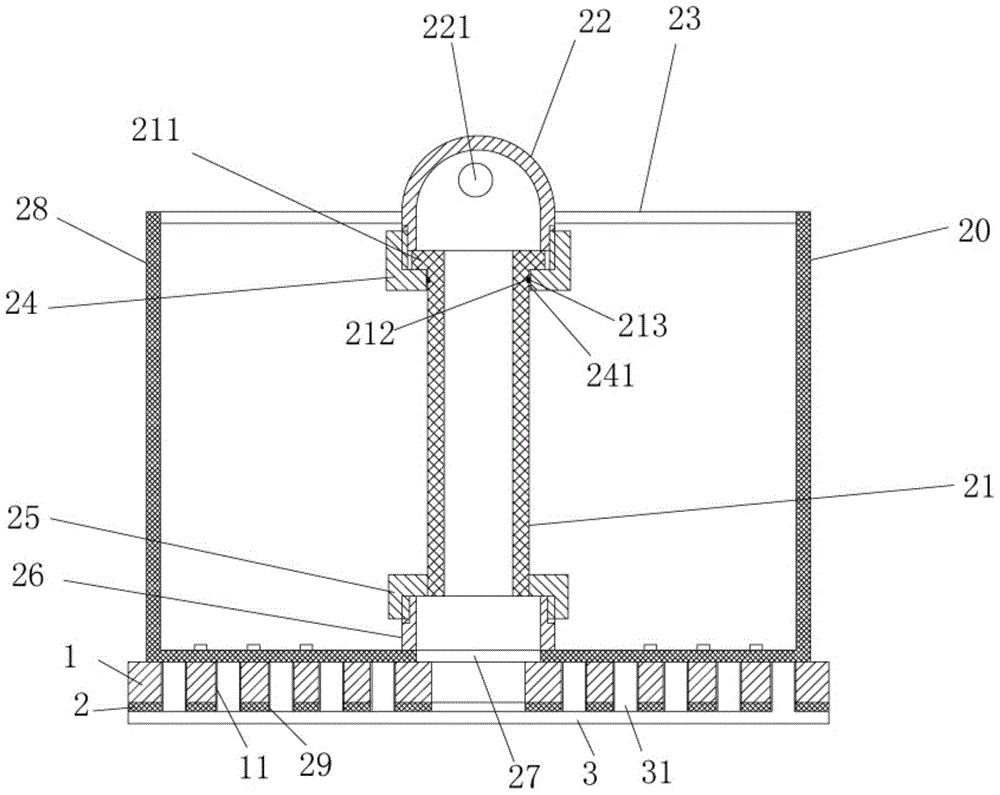

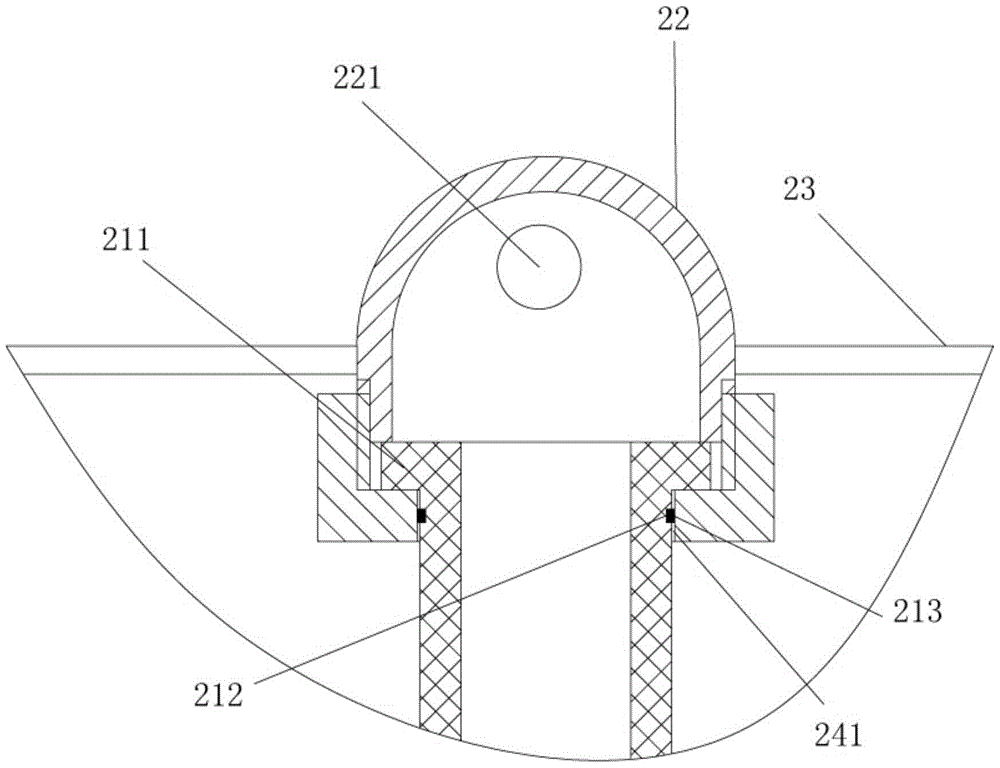

[0015] Examples, see e.g. Figures 1 to 2 Shown, a fiber cage for a loose fiber dyeing machine, comprising a frame 28, the top of the frame 28 has a connecting sleeve 22, the outer side wall of the connecting sleeve 22 is fixed with a plurality of support rods 23, the other end of the support rod 23 It is welded and fixed on the inner wall of the frame body 28, the bottom end of the connecting sleeve 22 is screwed with a fixed sleeve 24, the middle vertical pipe body 21 is inserted in the fixed sleeve 24, and the lower end of the middle vertical pipe body 21 is fixed with a lower connection. Cover 25, the lower connection sleeve 25 is screwed on the raised cover 26 that the bottom plate middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com