Patents

Literature

49results about How to "Adjust delivery speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

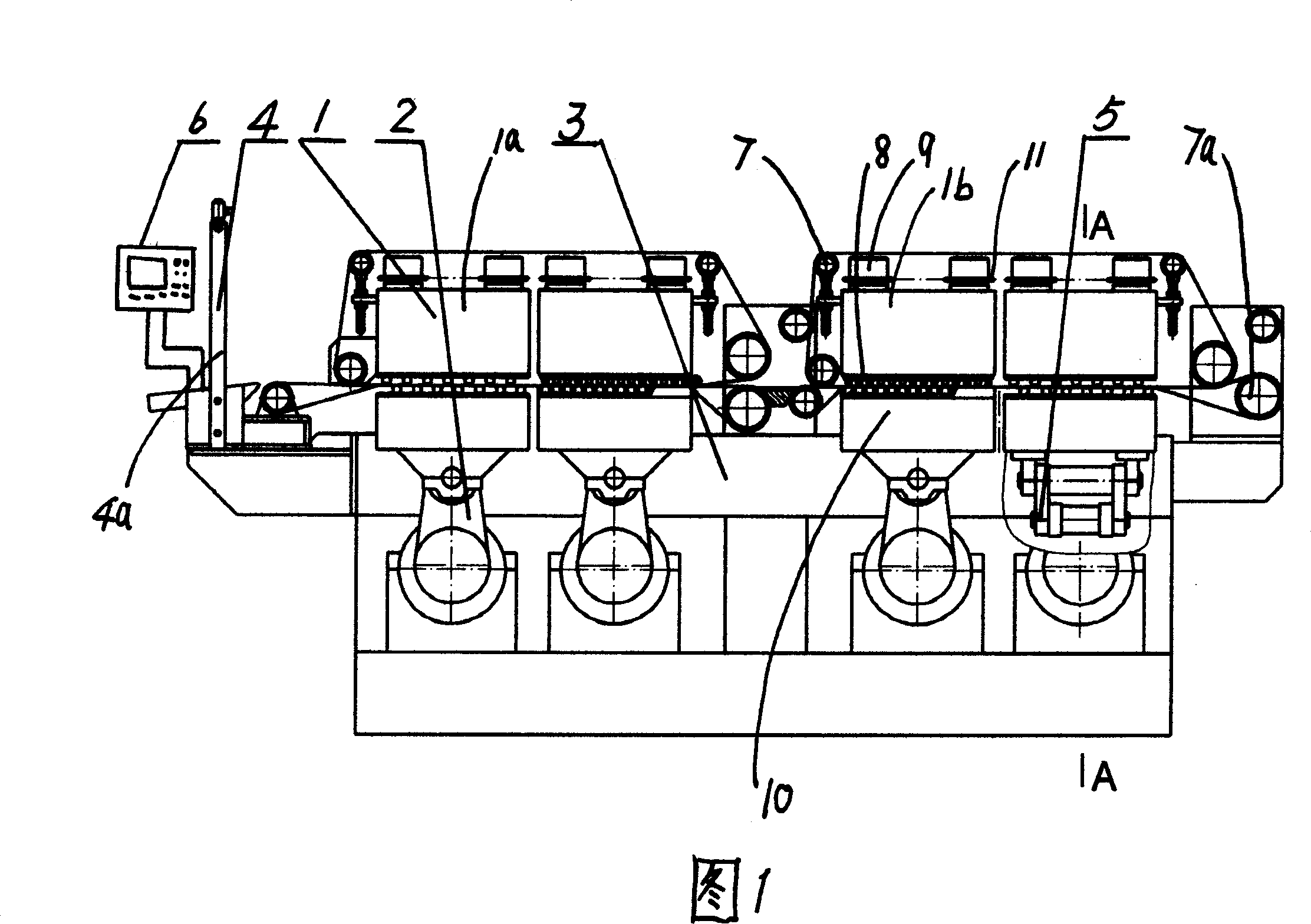

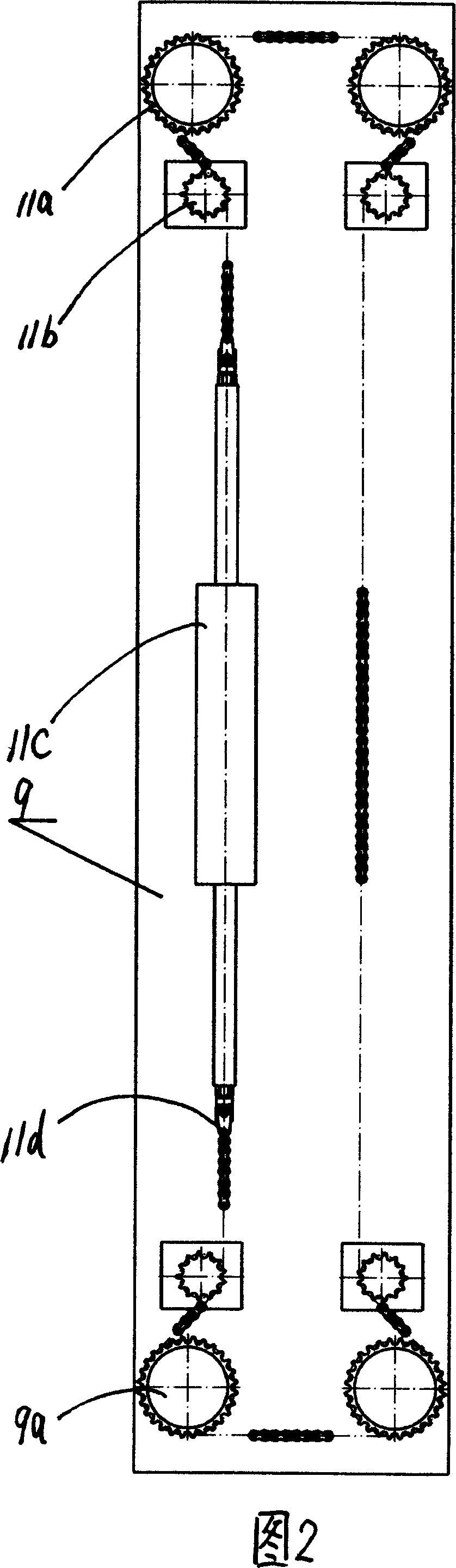

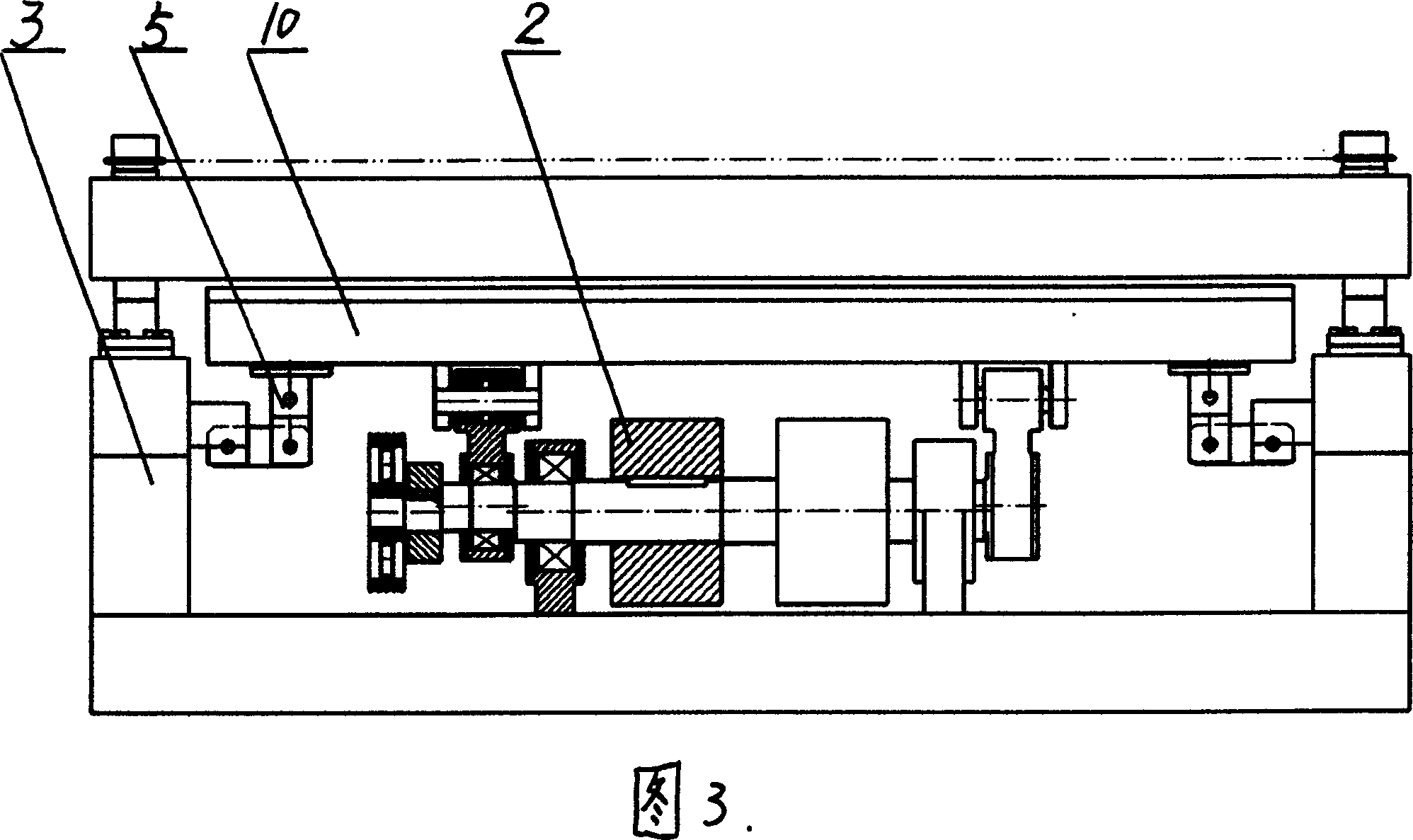

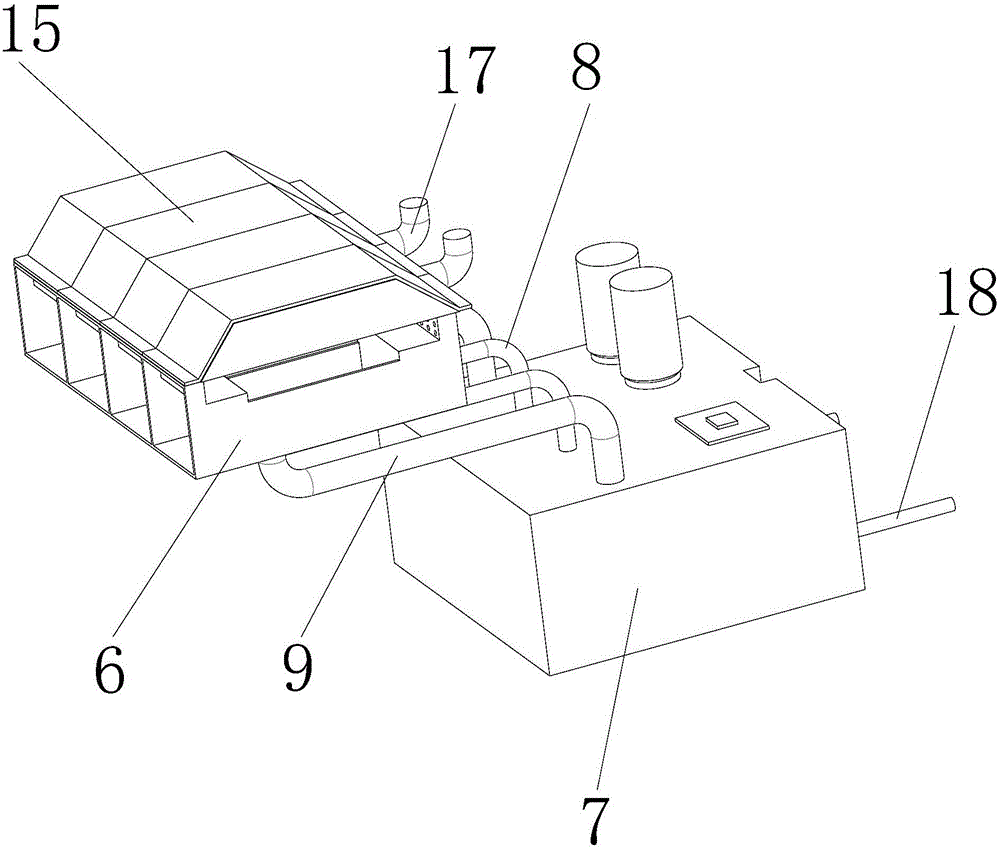

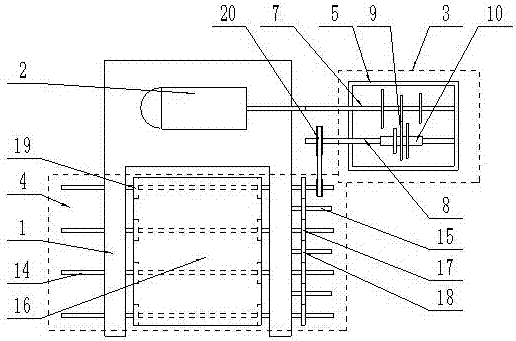

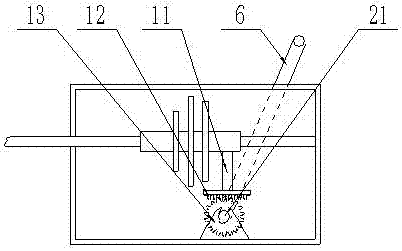

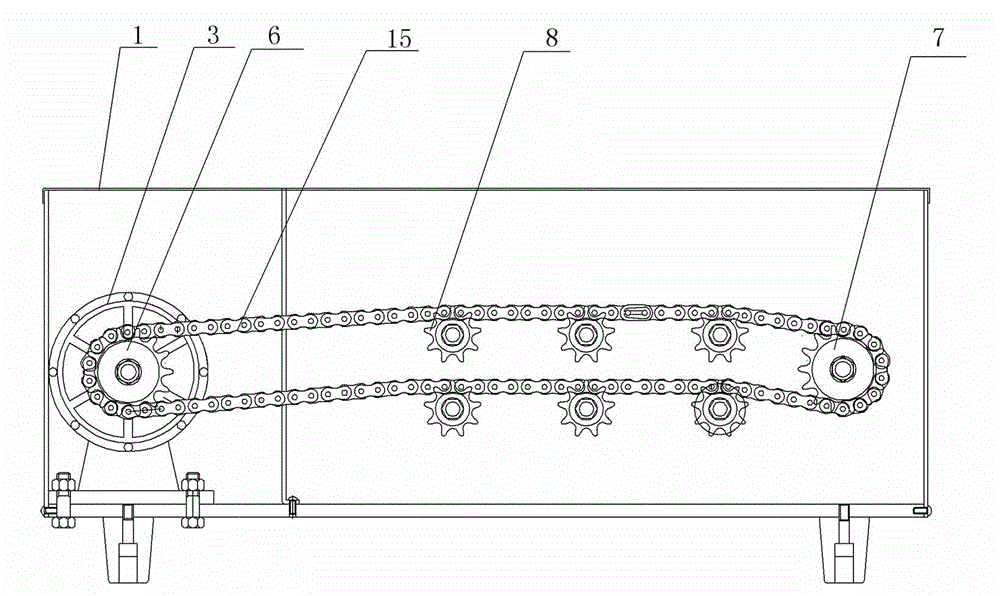

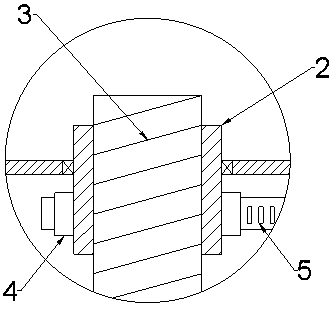

Composite type oscillation softening machine

The invention relates the vibration softening machine for handing leather, comprising softening structure and vibration structure. The softening structure and vibration structure is on rack; on softening structure or rack there is an injector; one end of the connection structure is connected with rack, and the other end of it is connected with lower-hole nail-plate seat of softening structure. The softening structure is designed separately, so it can be designed to combination form according to leather; the adjusting structure of softening structure can adjust the distance between topper hole nail-plate parts and lower-hole nail-plate seat; the injector releases the dust and eliminates the electrostatic; transporting velocity can be adjusted, so the handing operation velocity can also be adjusted; the computer controls the machine, so the leather has high quality.

Owner:张亚楠

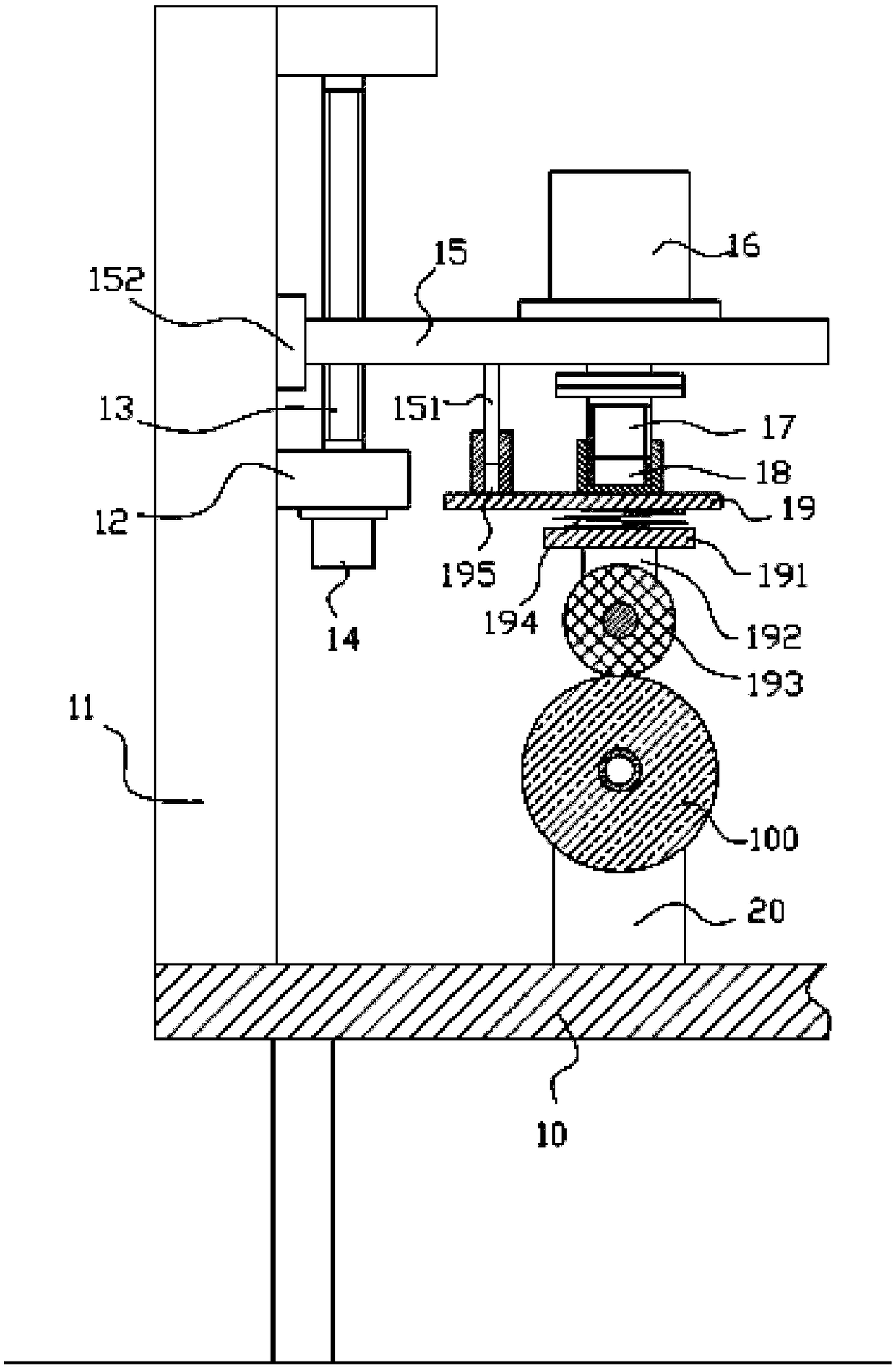

Connecting cloth embossing processing device

InactiveCN109049965AEasy to installIncrease delivery speedRotary pressesWebs handlingAgricultural engineering

The invention discloses a connecting cloth embossing processing device. The connecting cloth embossing processing device comprises a rack. A main vertical supporting plate is fixed to the top face ofthe left side of a top plate of the rack, a processing main vertical plate is fixed to the rear portion of top face of the middle of the top plate of the rack, an upper main transverse plate is fixedto the top face of the processing main vertical plate, and a main compression oil cylinder is fixed to the top face of the middle of the upper main transverse plate. A pushing rod of the main compression oil cylinder penetrates through the upper main transverse plate and is fixed with an upper lifting connecting plate, an upper connecting block is fixed to the middle of the bottom face of the upper lifting connecting plate, and the upper connecting block is hinged to a lower connecting block through a hinge shaft. An upper compression connecting plate is fixed to the bottom face of the lower connecting block, an upper heating plate is fixed to the bottom face of the upper compression connecting plate, and an upper embossing mold plate is fixed to the bottom face of the upper heating plate.According to the connecting cloth embossing processing device, continuous embossing can be realized, a distributing reel drum and a receiving reel drum can be installed conveniently, the connecting block is hinged and fixed to the two ends of the distributing reel drum and the two ends of the distributing reel drum are directly installed on a fixing supporting plate, thus fixing is solid, and notprone to being fell off.

Owner:SUZHOU RUIRI TEXTILE SCI & TECH

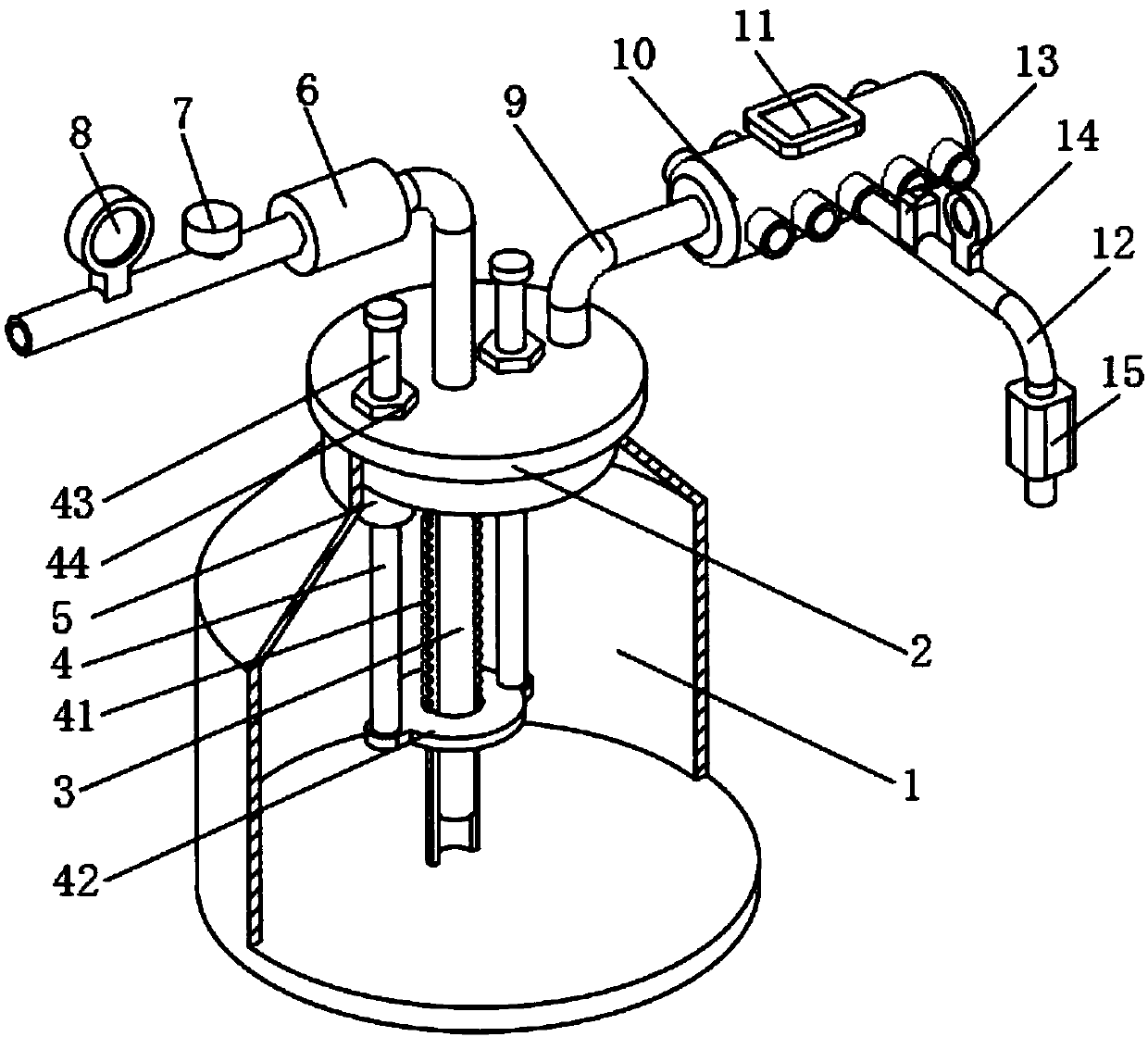

Breathing machine device for paediatrics

The invention discloses a breathing machine device for paediatrics, which comprises a humidifying bottle; the bottom opening of the humidifying bottle is provided with a bottle plug, and the upper surface of the bottle plug is provided with an air inlet pipeline; an air outlet of the air inlet pipeline is located in the middle of the inside of the humidifying bottle, the lower end of the side faceof the air inlet pipeline is provided with a humidifying adjusting device; an air inlet pipe opening of the air inlet pipeline is connected to an air outlet pipe opening of an external oxygen pipeline, and the left end of the side face of the air inlet pipeline is provided with a first pressure gauge,; the middle part of the side face of the air inlet pipeline is provided with an adjusting valve,and the right end thereof is provided with a filter; the right end of the upper end face of the bottle plug is provided with a connecting pipe, and the air inlet pipe opening of the connecting pipe is located at the upper end of the inner part of the humidifying bottle. The breathing machine device for paediatrics is simple in structure and able to filter oxygen, detect and adjust oxygen humidity, detect air pressure in the conveying pipeline, adjust the oxygen conveying speed, and convenient to use by infants; besides, the breathing machine is simple in operation and convenient to use.

Owner:田芳

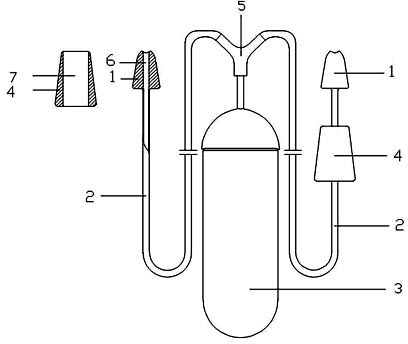

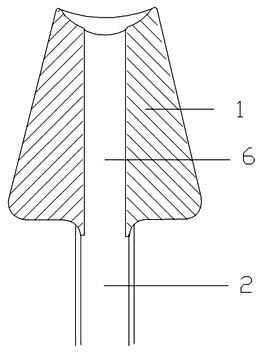

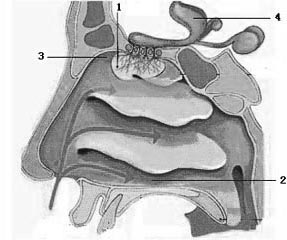

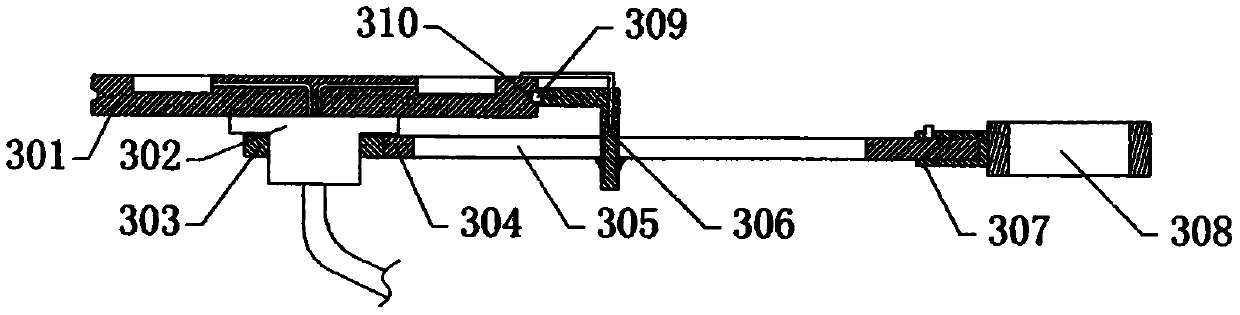

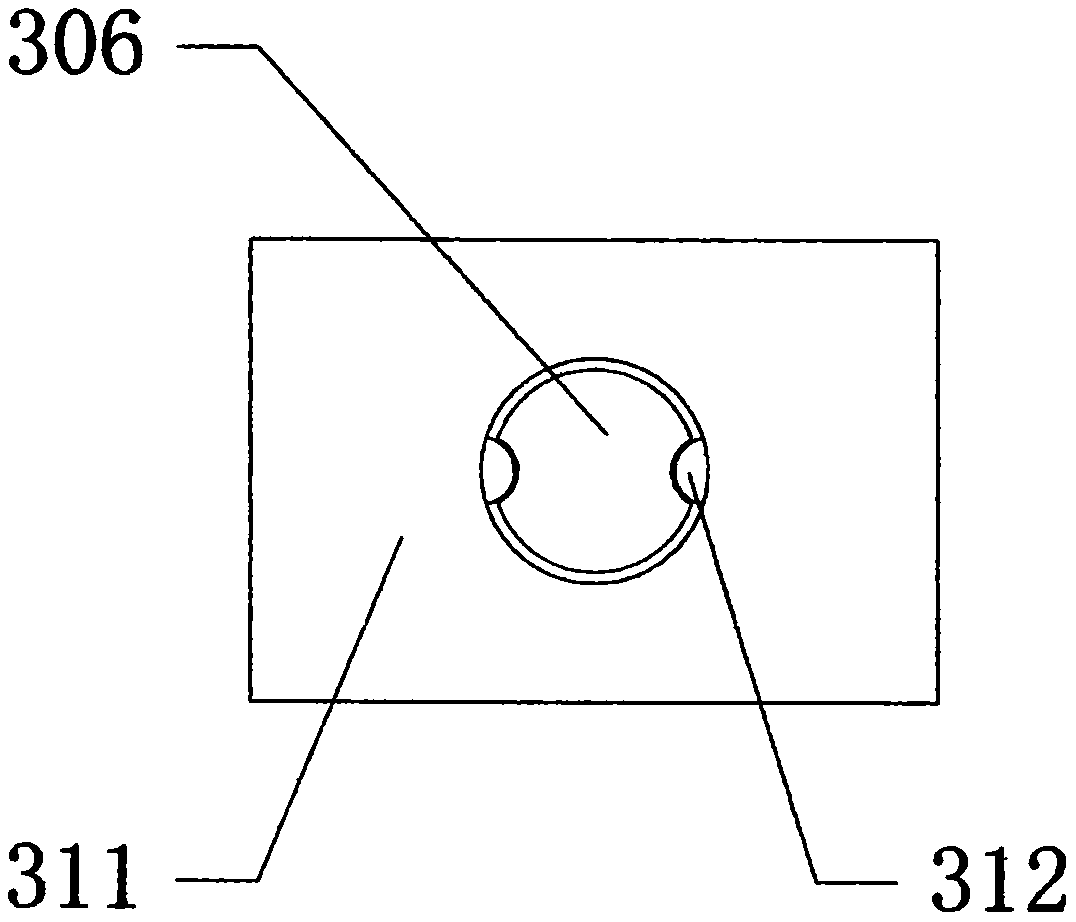

Double-nasal cavity continuous nasal administration device and using method thereof

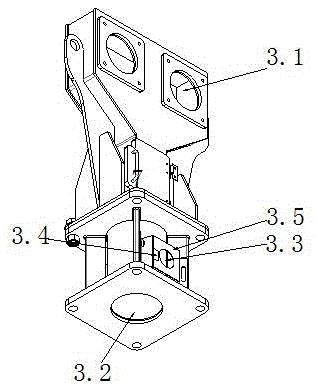

InactiveCN101979109AAdjust delivery volumeAdjust delivery speedMedical devicesNasal Cavity EpitheliumOsmotic pump

The invention discloses a double-nasal cavity continuous nasal administration device and a using method thereof. The device comprises an osmotic pump (3), PE pipes (2), a medicament releasing head (1), a protective sleeve (4) and a tee pipe (5), wherein the osmotic pump (3) is communicated with two PE pipes (2) through the tee pipe (5); opposite ends of the two PE pipes (2) and the tee pipe (5) are communicated with one medicament releasing head (1) respectively; the medicament releasing head (1) is regular cone-shaped and a passage (6) in the medicament releasing head (1) is communicated with the PE pipes (2); the protective sleeve (4) is an independent body and is a regular frustum body corresponding to the medicament releasing head (1); the minimal inner diameter of the inner cavity passage (7) of the protective sleeve (4) is slightly greater than the maximal outer diameter of the medicament releasing head (1), so that the medicament releasing head (1) can conveniently slide in the inner cavity passage (7); and the protective sleeve (4) is used for sealing the inferior nasal meatus of the nasal cavity of a human body. The device can realize continuous administration and double-nasal cavity administration and prevents a medicament releaser from entering the oropharynx. The using method is simple and convenient.

Owner:刘新峰

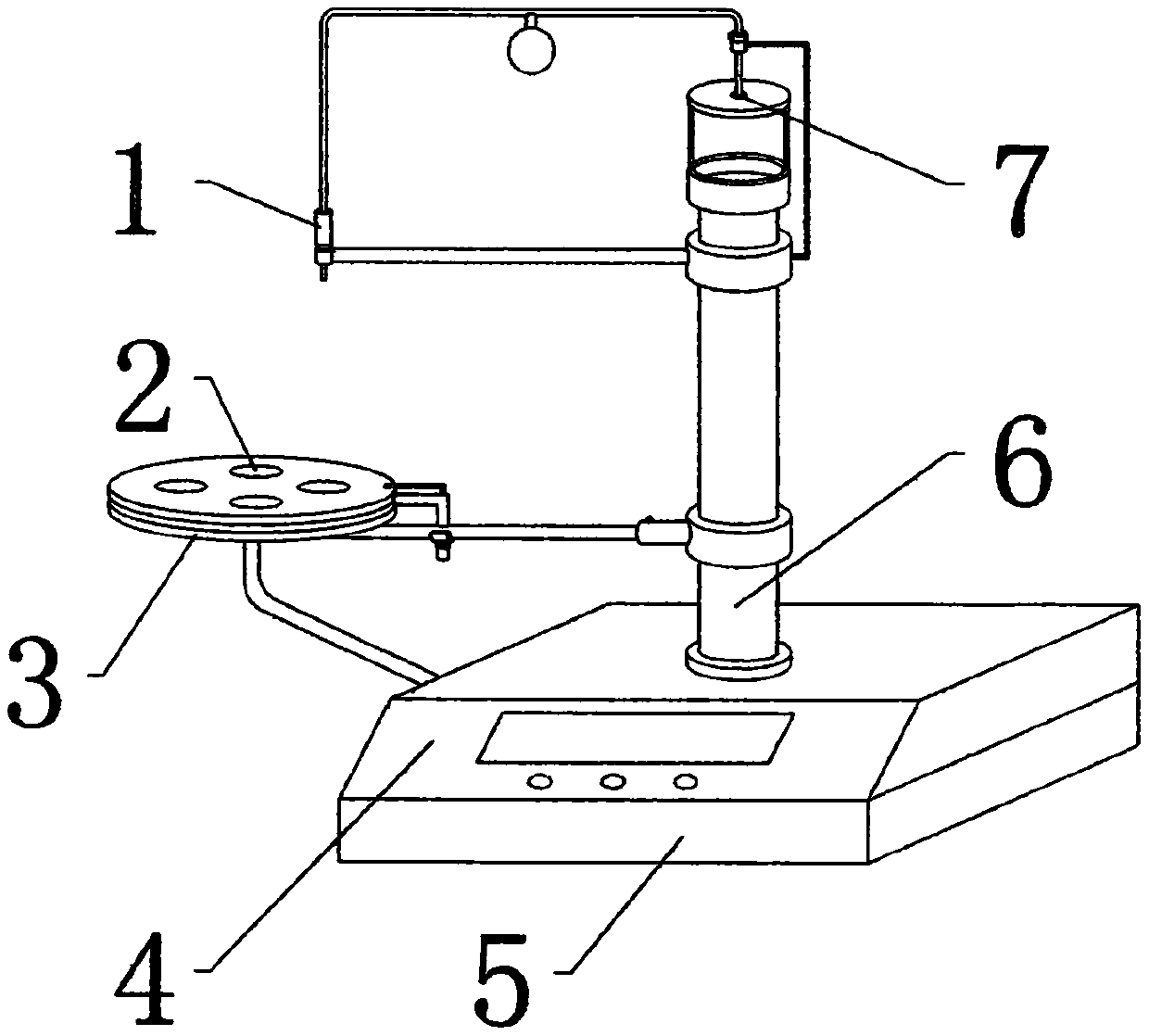

Pharmacological electronic titrator device

InactiveCN109633080AAchieving the purpose of rotational titrationWide titration rangeChemical analysis using titrationEngineeringTitration

The invention provides a pharmacological electronic titrator device, which comprises a titrator body. The upper end of the titrator body is fixedly connected with a fixing rod through a flange; the annular side surface of the fixing rod is fixed with a supporting mechanism; the upper end of the supporting mechanism is fixed and embedded with a titrated probe; the top part of the annular side surface of the fixing rod is fixed with a stirring mechanism; the stirring mechanism is communicated with a titrating pipe; the supporting mechanism comprises a turntable, a T-shaped support, a first supporting ring, a first connecting rod, a sliding groove, an L-shaped sliding rod, a casing, a first fixing ring, a ball and an annular limit groove; and the stirring mechanism comprises a second supporting ring, a second connecting rod, a second fixing ring, a supporting disc, a guide rod, a sealing plate, a first round pipe, a second round pipe, a negative pressure air bag, a conveying pipeline andan adjusting bolt. Compared with the prior art, the pharmacological electronic titrator device has the following beneficial effects that the purpose of rotary titration is realized; the titration range is wide; disassembly and placement are facilitated; the purpose of uniformly stirring liquid medicine is also realized; and the supporting stability is improved.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

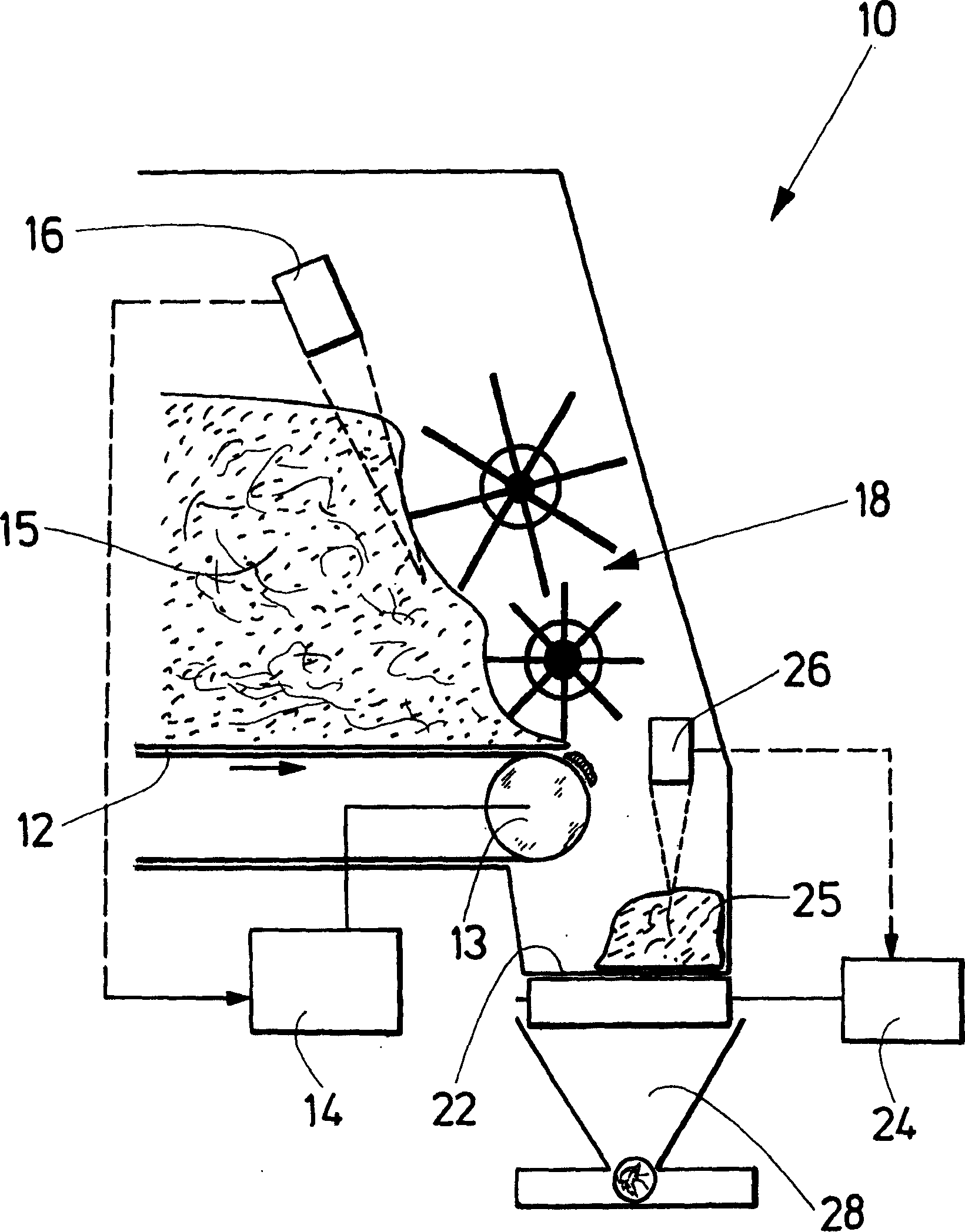

Unloading tobacco material from an intermediate reservoir

InactiveCN1714689AAchieve precision distributionAdjust delivery speedCigarette manufactureEngineeringIntermediate storage

The present invention relates to a method that is used for material discharging material and is used for discharging tobacco-rag materials (15) from an intermediate storage device (10), wherein, the tobacco-rag materials (15) in the intermediate storage device (10) are conveyed to a discharging device (18) which can separate one component (25) of the tobacco-rag materials (15) from the intermediate storage device (10), and then delivers the separated component (25) to a tobacco-rag material stream. The method of the present invention is characterized in that: at the output end of the intermediate storage device (10), at least one sensing-detection device (26) is used for detecting the separated component (25) of the tobacco-rag materials and allocates allocating the component (25) that is delivered to the tobacco-rag material stream according to the detected component (25) of the tobacco-rag materials. In addition, the tobacco-rag materials (15) in the intermediate storage device (10) can be delivered to a discharging device (18) that can separate one component (25) from the intermediate storage device (10) and can deliver the separated component (25) to a tobacco-rag stream.

Owner:HAUNI PRIMARY

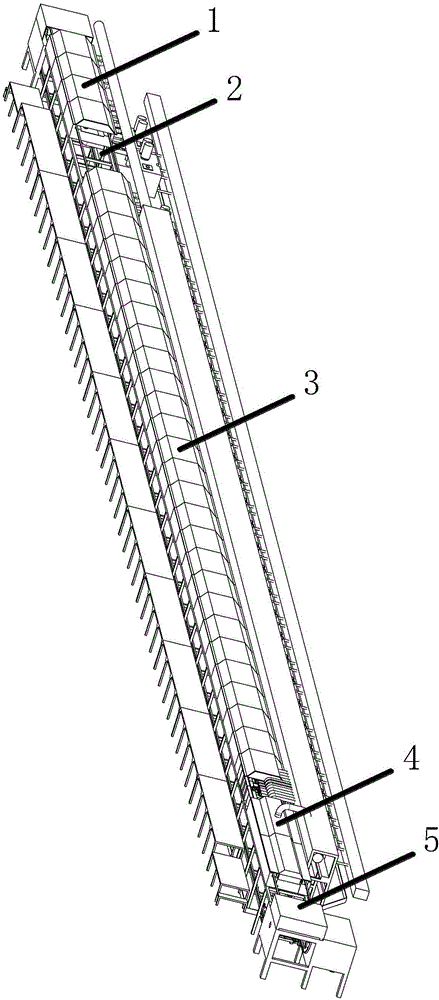

Automated electroplating production line

ActiveCN106544718AGuaranteed PlatingEffective quality controlElectrolysis componentsEngineeringElectroplating

The invention discloses an automated electroplating production line. A hanging rack cleaning section, a hanging rack feeding and discharging station section, an electroplating section, a drying station section and an unloading station section are connected in sequence through a circulating conveying line. The electroplating section comprises electroplating devices. Each electroplating device comprises an auxiliary tank and a main tank, wherein electroplating liquid in the main tank is conveyed into the auxiliary tank through water drawing pipes, electroplating liquid in the auxiliary tank flows back into the main tank through backflow pipes, and blowing mechanisms which blow away liquid on the surfaces of workpieces are arranged at the two ends, in the conveying direction of the conveying line, of the auxiliary tank correspondingly. By means of the automated electroplating production line, residual cleaning water or electroplating liquid on the surfaces of the workpieces are blown away through the blowing mechanisms, so that the cleaning water is prevented from entering the electroplating liquid and lowering the concentration of the electroplating liquid due to dilution, the electroplating quality is guaranteed, and the effect that the thickness of an electroplating layer meets the design requirement is ensured; and besides, electroplating liquid carried out by the workpieces can be recycled and reused, so that waste of electroplating liquid is reduced, the production cost is reduced, pressure of subsequent cleaning is relieved, and consumption of cleaning water is reduced.

Owner:DEYANG ZHIDA PRECISION ELECTRONICS

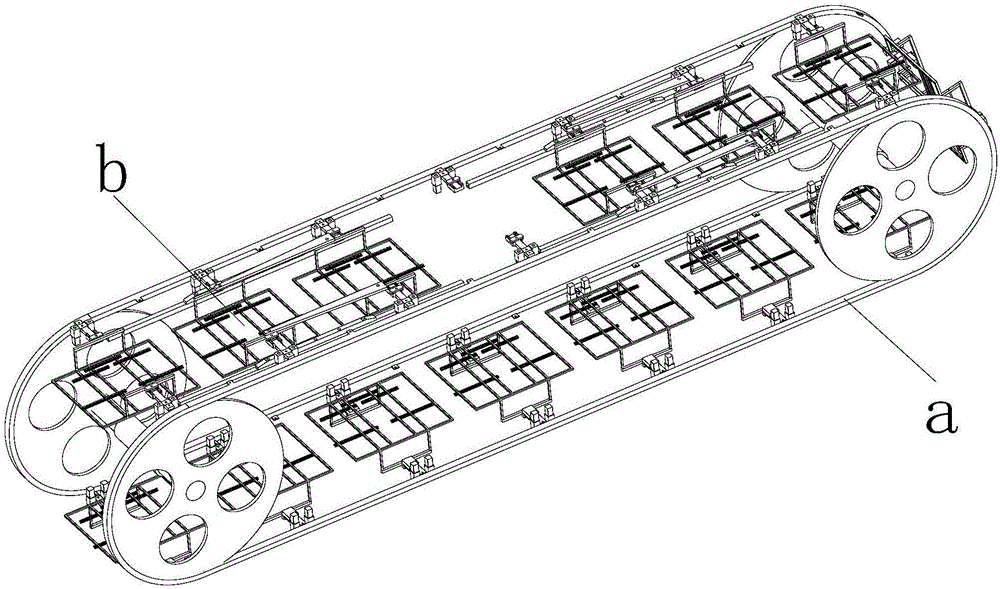

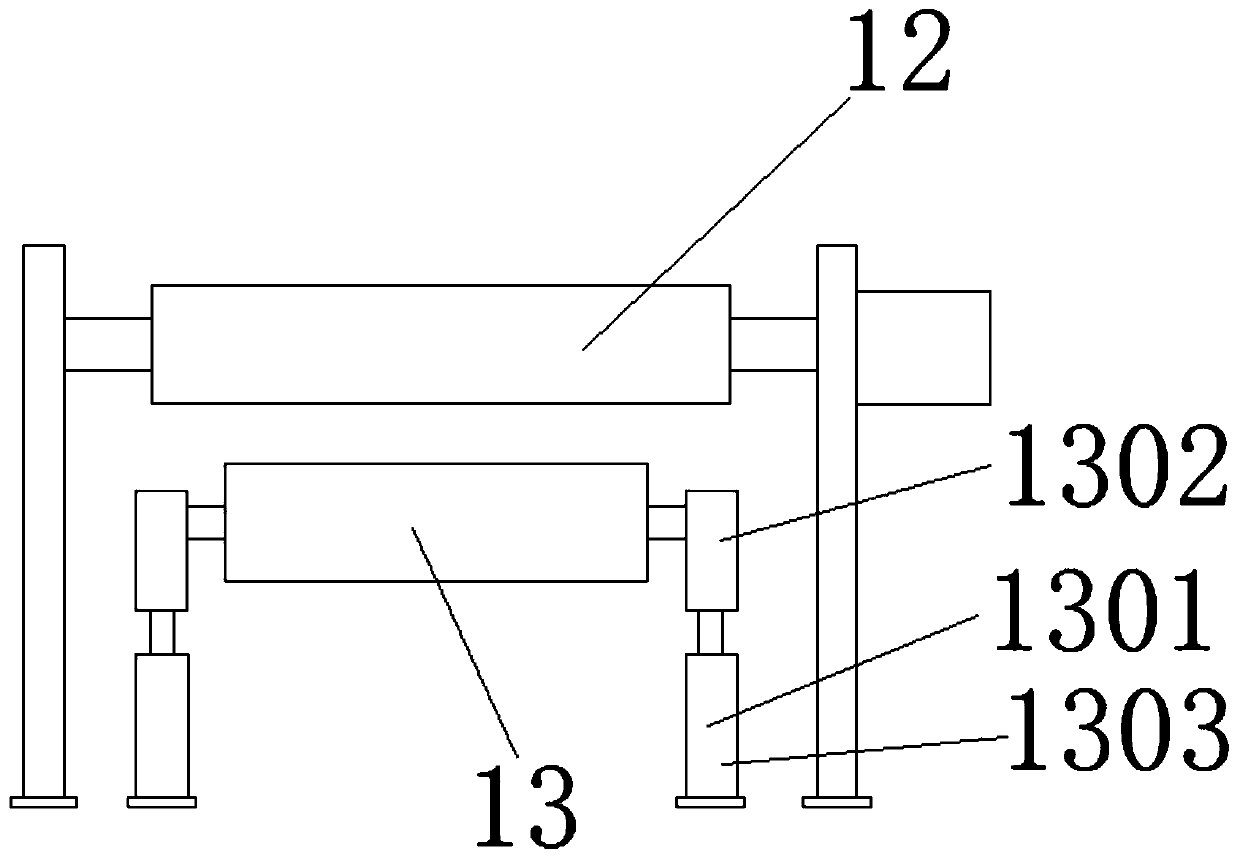

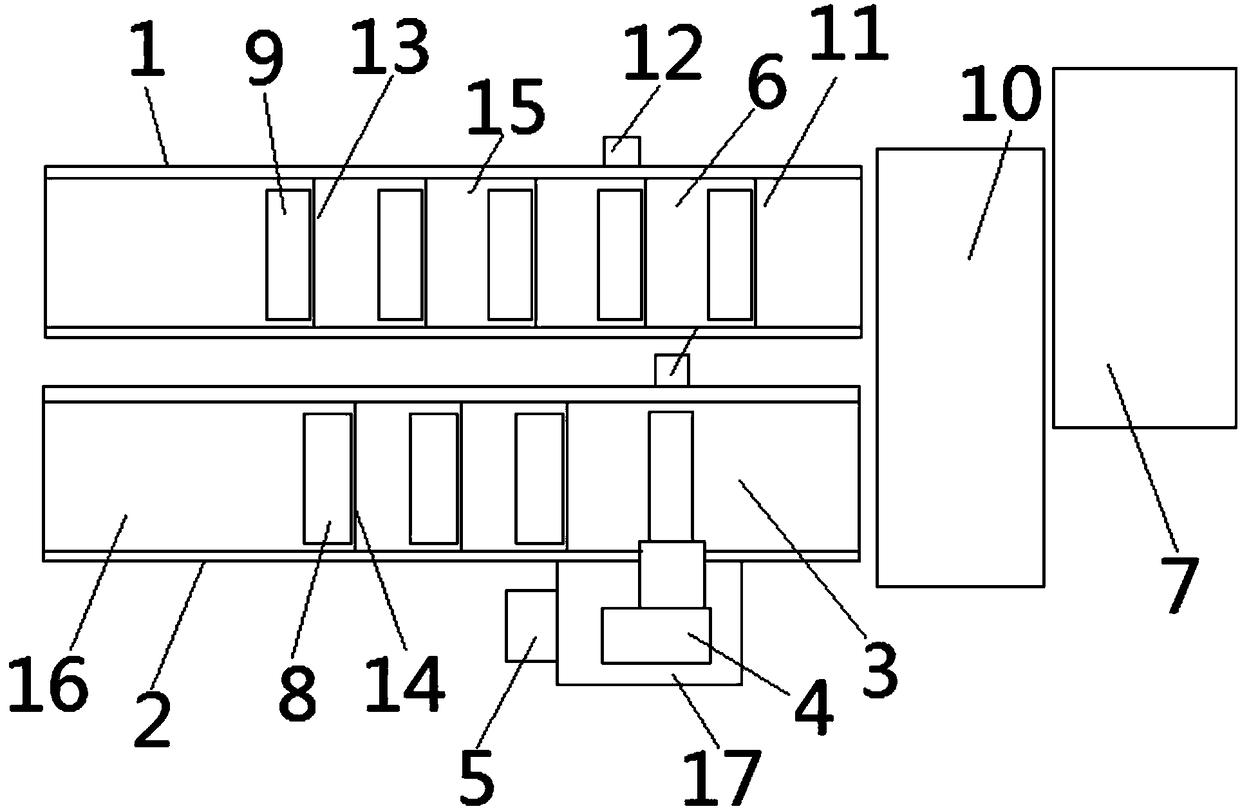

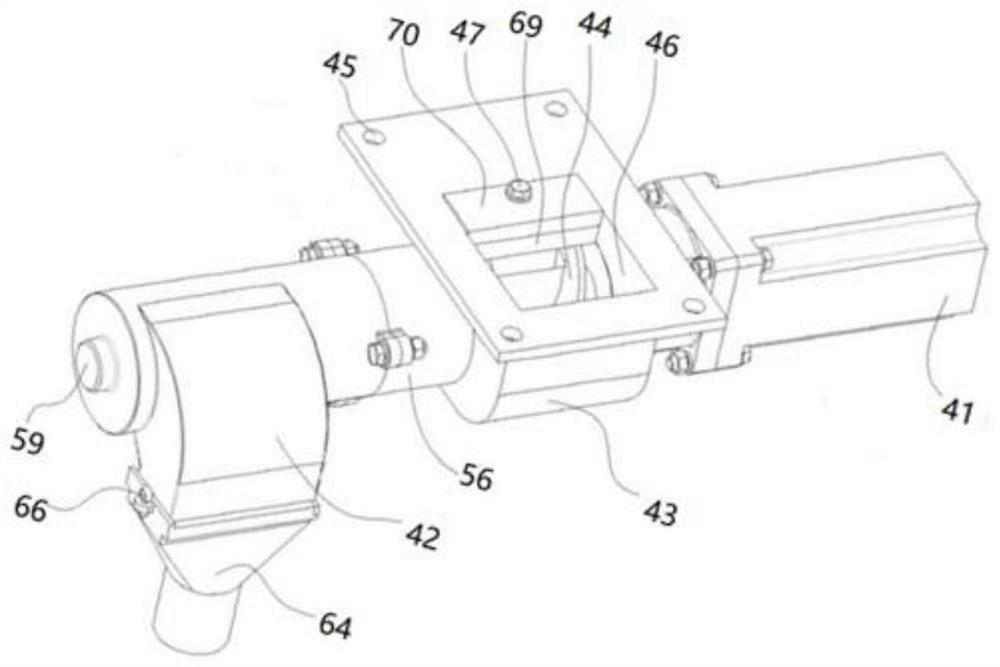

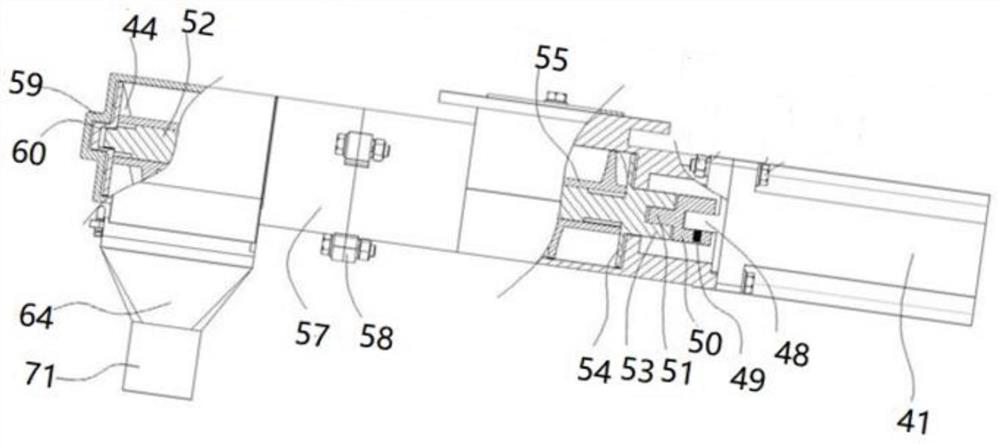

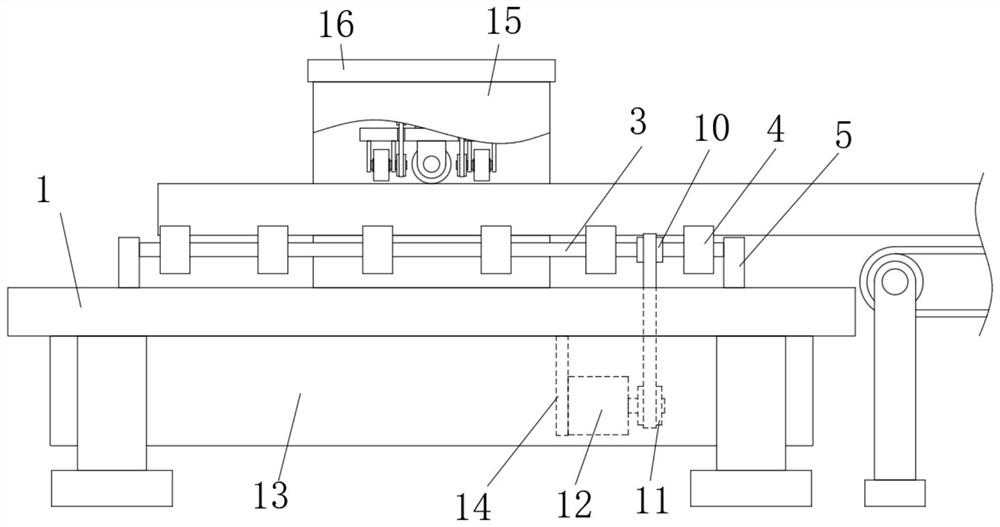

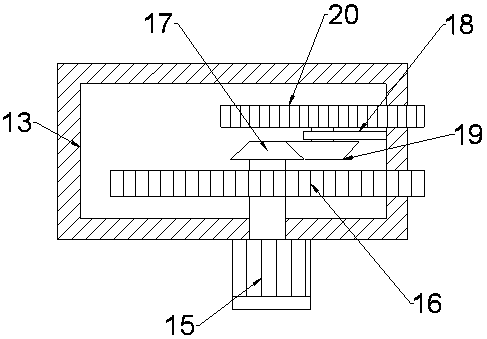

Plate conveying device with speed regulating function

The invention discloses a plate conveying device with a speed regulating function. The plate conveying device comprises a bracket, a motor, a speed regulating mechanism and a transmission mechanism, wherein the speed regulating mechanism comprises a speed regulating box, a speed regulating rod, a first transmission shaft, a second transmission shaft and a plurality of groups of gears; the first transmission shaft and the second transmission shaft are mounted in the speed regulating box; a shaft sleeve is arranged on the second transmission shaft; the plurality of groups of gears are mounted on each of the first transmission shaft and the shaft sleeve; the shaft sleeve is connected with a sliding block; a toothed rack structure is arranged on the lower surface of the sliding block; the sliding block is connected with a pinion through the toothed rack structure; and the pinion is connected with the speed regulating rod. The plate conveying device has the benefits as follows: the conveying speed can be regulated, the use is flexible and convenient, and the structure is simple and efficient.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

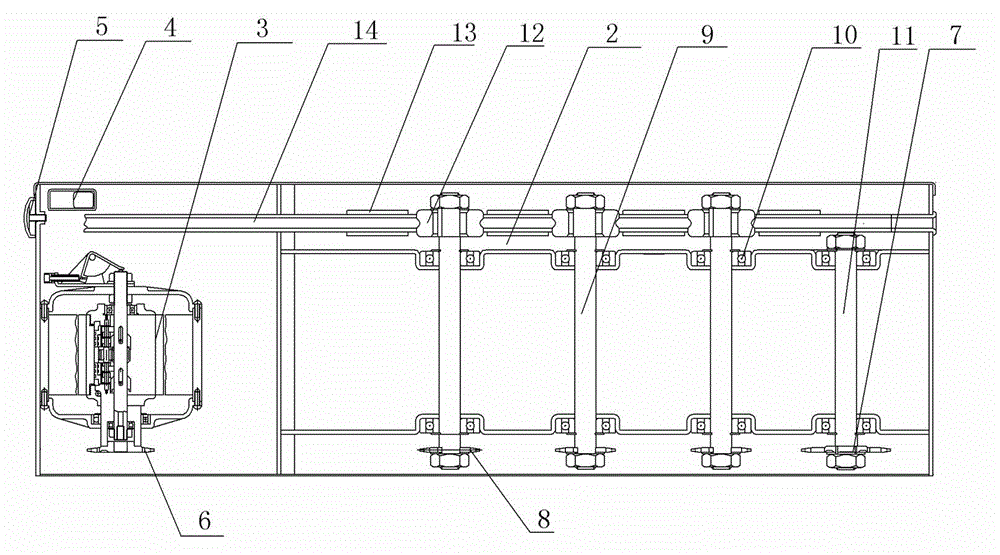

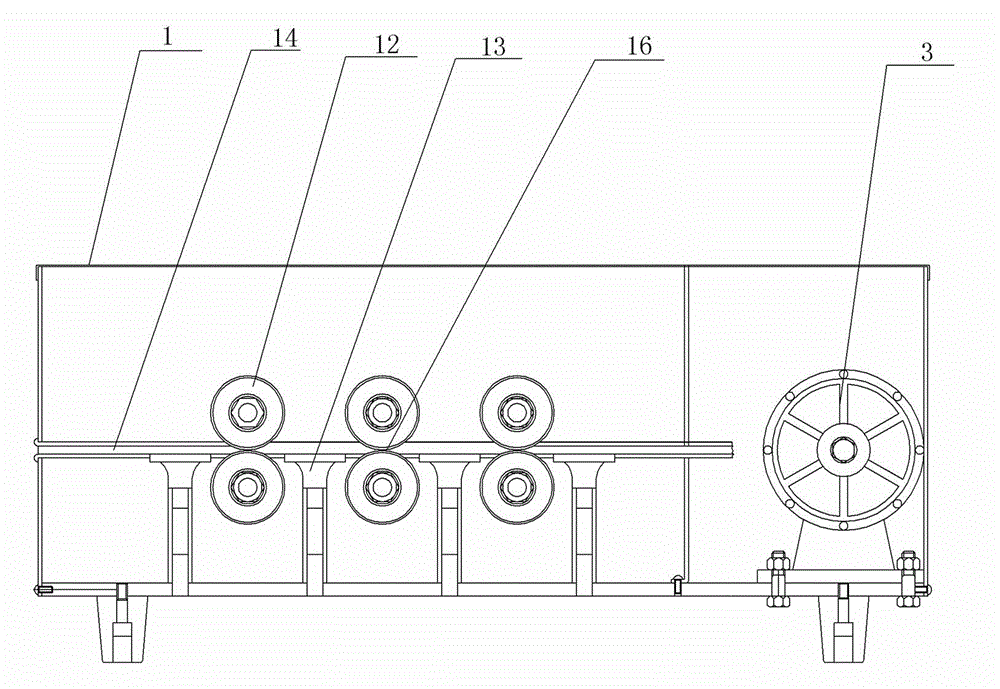

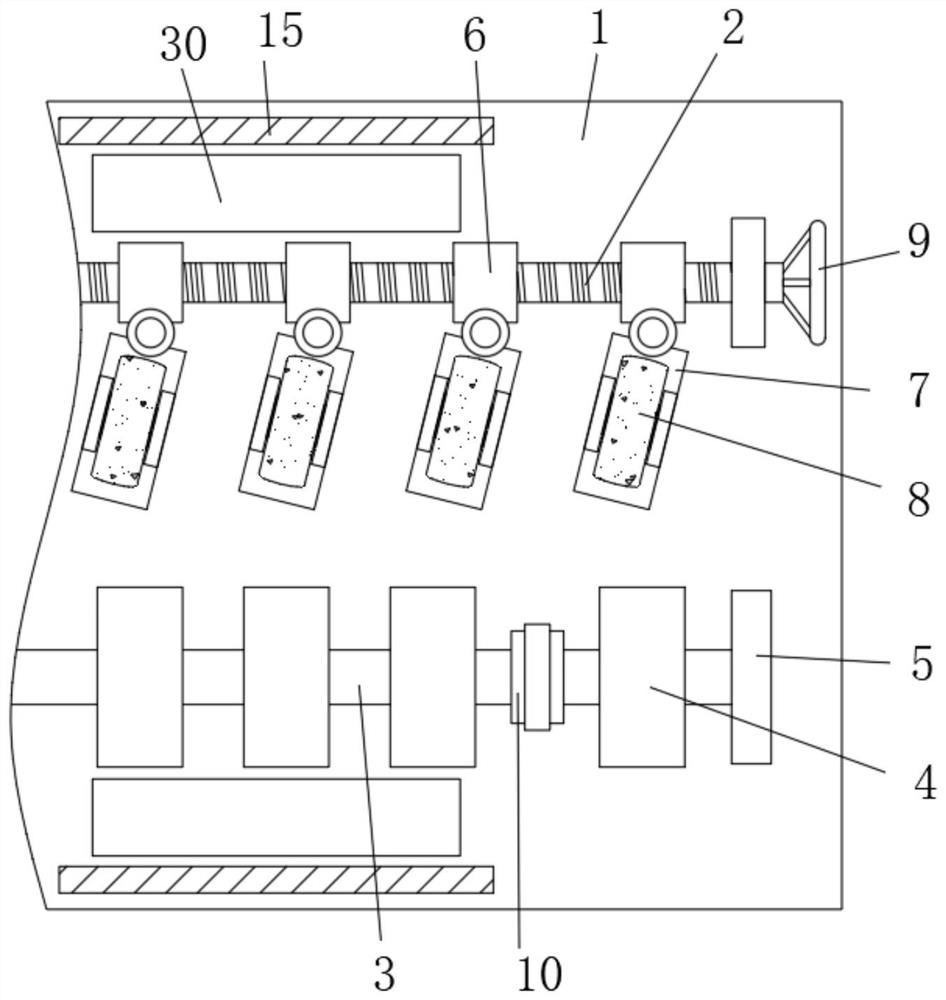

Conveyer device

The invention discloses a conveyer device, and the conveyer device comprises a shell body, a support and an electrical machine. A rotating shaft of the electrical machine is fixedly connected with a driving sprocket. The support is further provided with a transitional sprocket, wherein the transitional sprocket is in driving connection with the drive sprocket arranged on the electrical machine through a chain which is closed to be annular. The support is provided with multiple sets of conveying wheel mechanisms which are arranged horizontally. Each of the conveying wheel mechanisms comprises two rotating shafts which are connected with the support in a rotating mode, wherein one of the two rotating shafts is arranged above the other rotating shaft. Two conveying wheels with V-shaped wheel troughs are arranged at one ends of the two rotating shafts. A conveying interspace is arranged between the two conveying wheels. The support is further provided with a conveying passage, wherein two ends of the conveying passage penetrate through the shell body. The conveying interspace between the two conveying wheels of each the set of conveying wheel mechanism is communicated with the conveying passage. Two driving sprockets are arranged at the one ends of the two rotating shafts. The bottom of the upper portion of the chain is meshed with the driving sprocket above each the set of the conveying wheel mechanisms. The bottom of the lower portion of the chain is meshed with the driving sprocket under each the set of the conveying wheel mechanisms.

Owner:NANTONG XUNXIANG AUTOMATION EQUIP

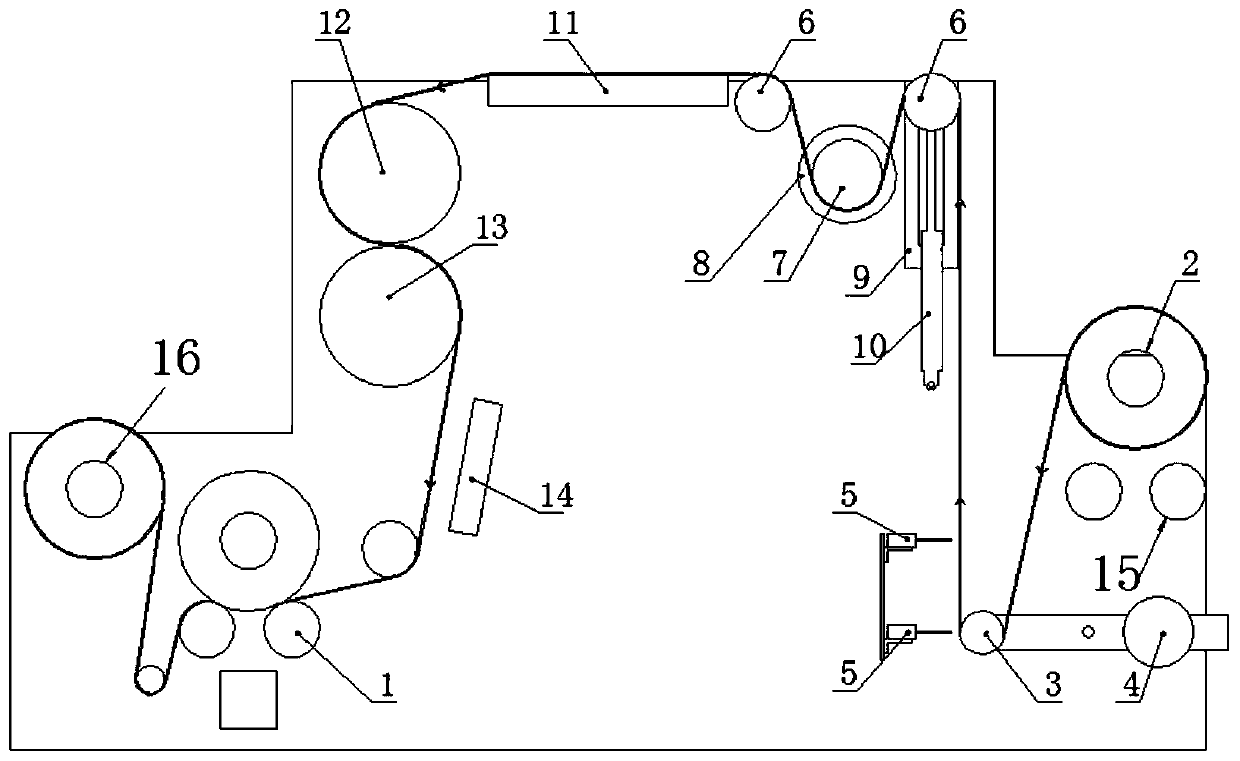

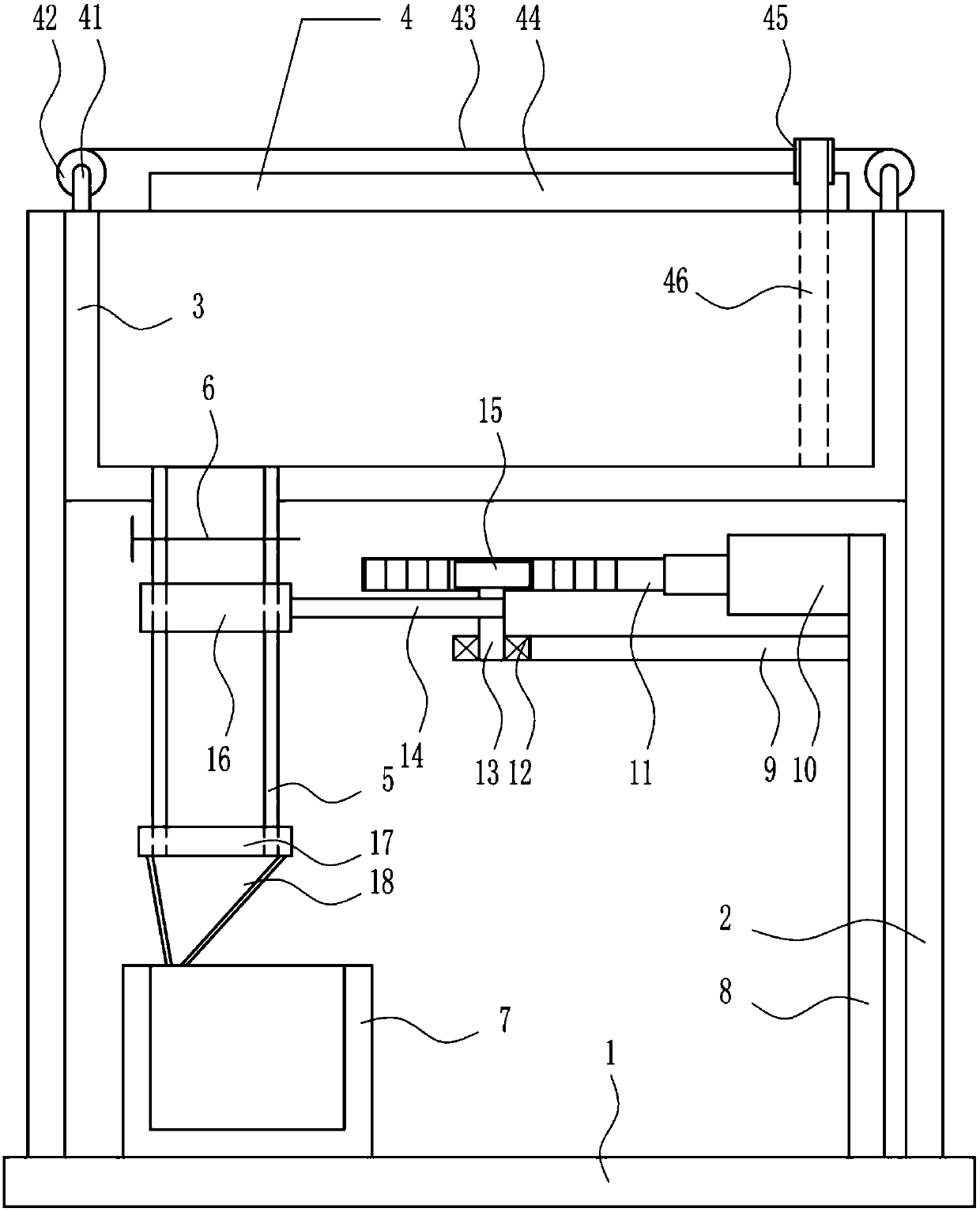

UV machine with damping material collecting and discharging structure

InactiveCN111497469AReduce tensionImprove printing effectOther printing apparatusWebs handlingComputer printingEngineering

The invention provides a UV machine with a damping material collecting and discharging structure, and belongs to the technical field of UV printer equipment. The UV machine comprises a discharging airexpansion roller, a discharging tensioning roller, a first steering roller, a damping roller, a second steering roller, a printing platform, a main driving roller, a lower pressing roller, a lamp box, a material receiving supporting roller and a material receiving air expansion roller which are sequentially arranged, wherein the tensioning degree of a material belt can be well adjusted through the discharging tensioning roller, different balance weights can be arranged, the tensioning degree can be adjusted through the first steering roller, the conveying speed of the material belt can be well adjusted through the damping roller, the influence of too fast conveying of the material belt on the tensioning degree is reduced, a driving lower pressing roller is arranged, the material belt canbe pressed before printing, the tensioning degree of the material belt during printing is further guaranteed, and the printing effect of the material belt can be better.

Owner:南通东川数码科技有限公司

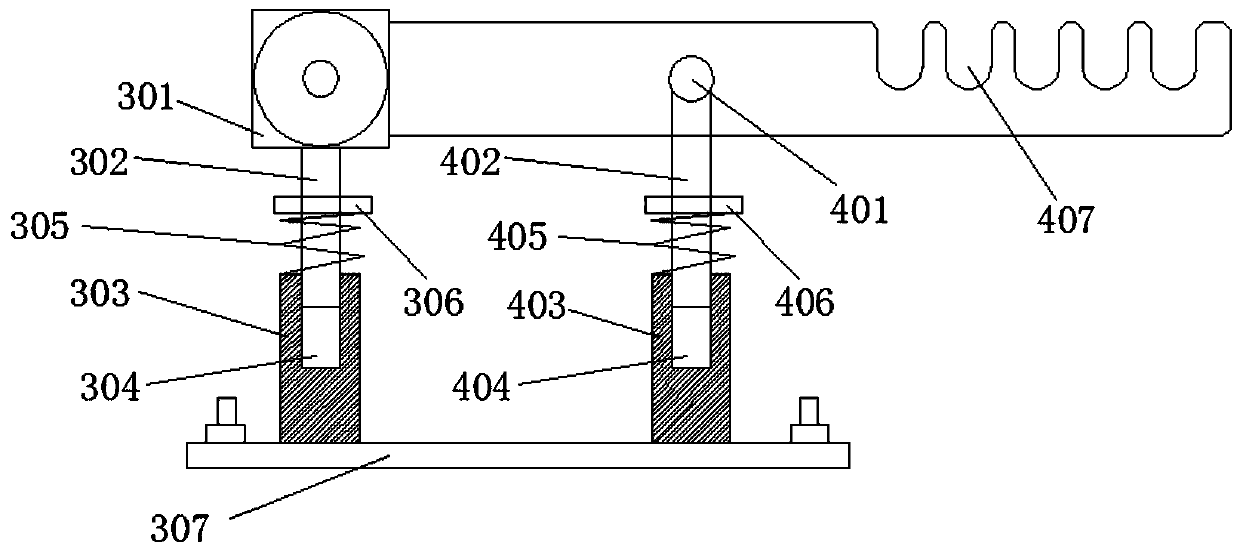

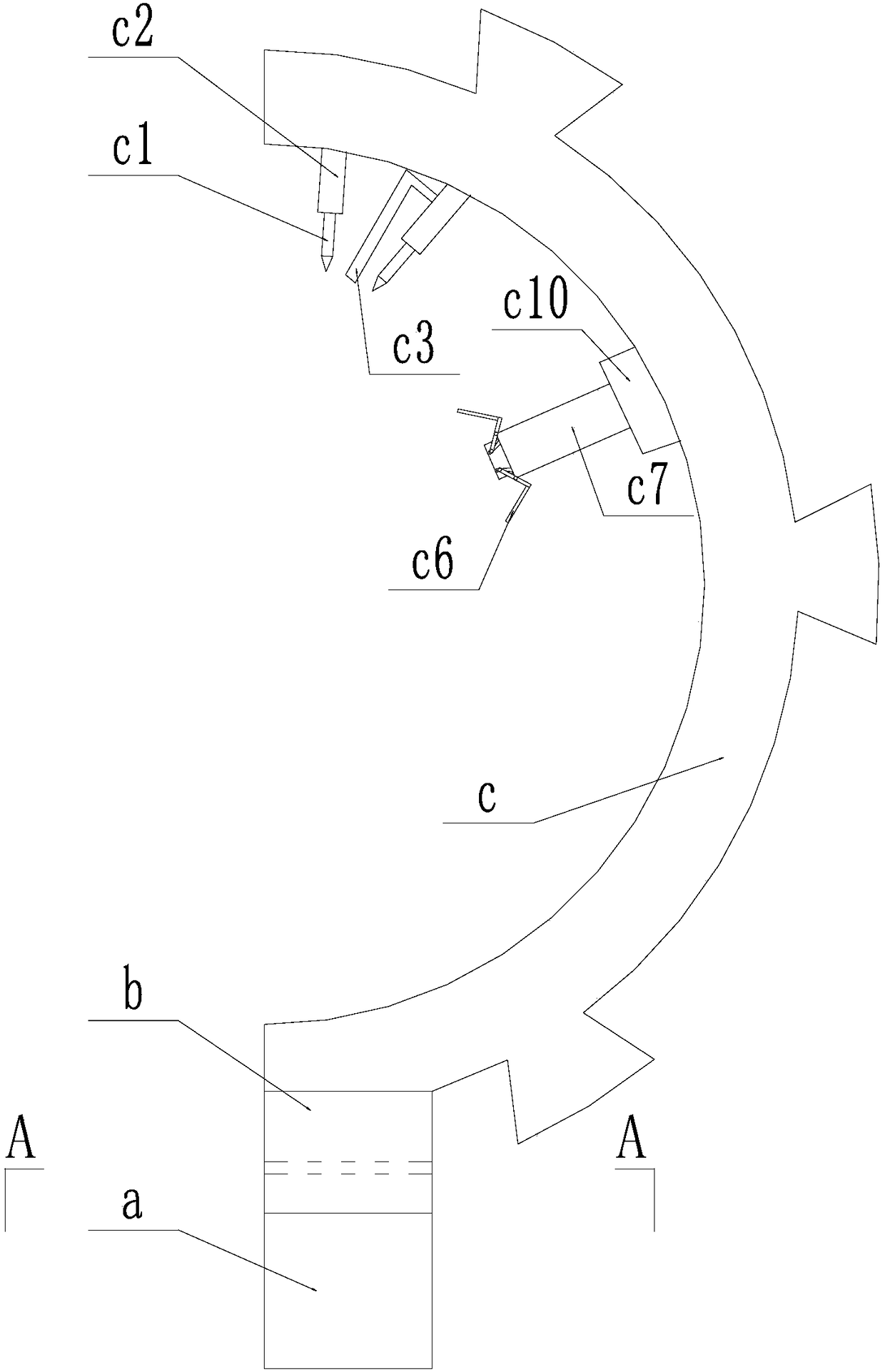

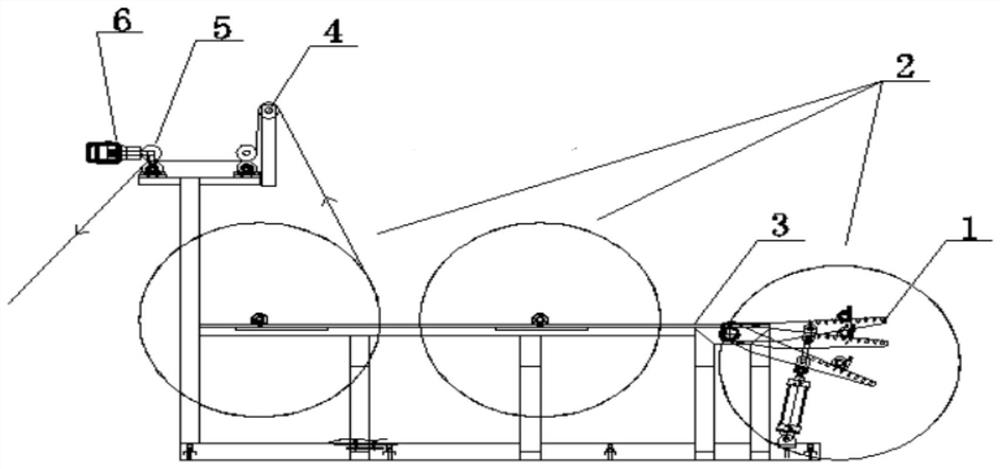

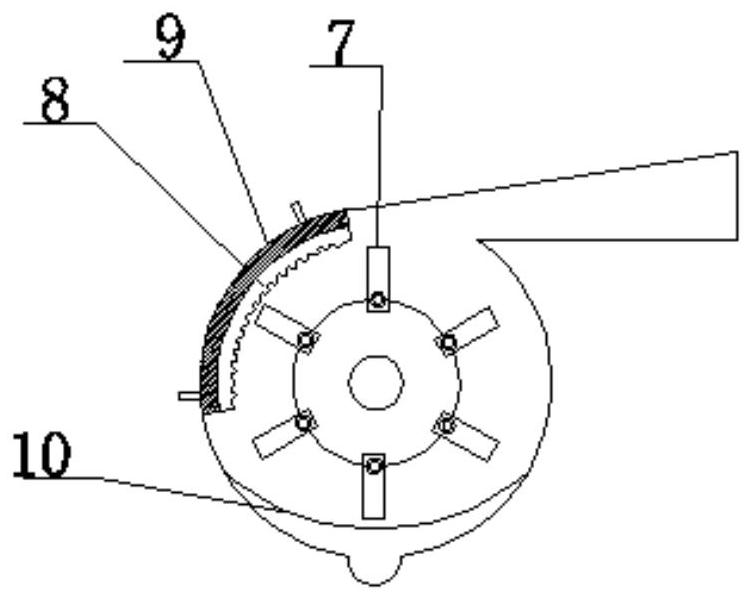

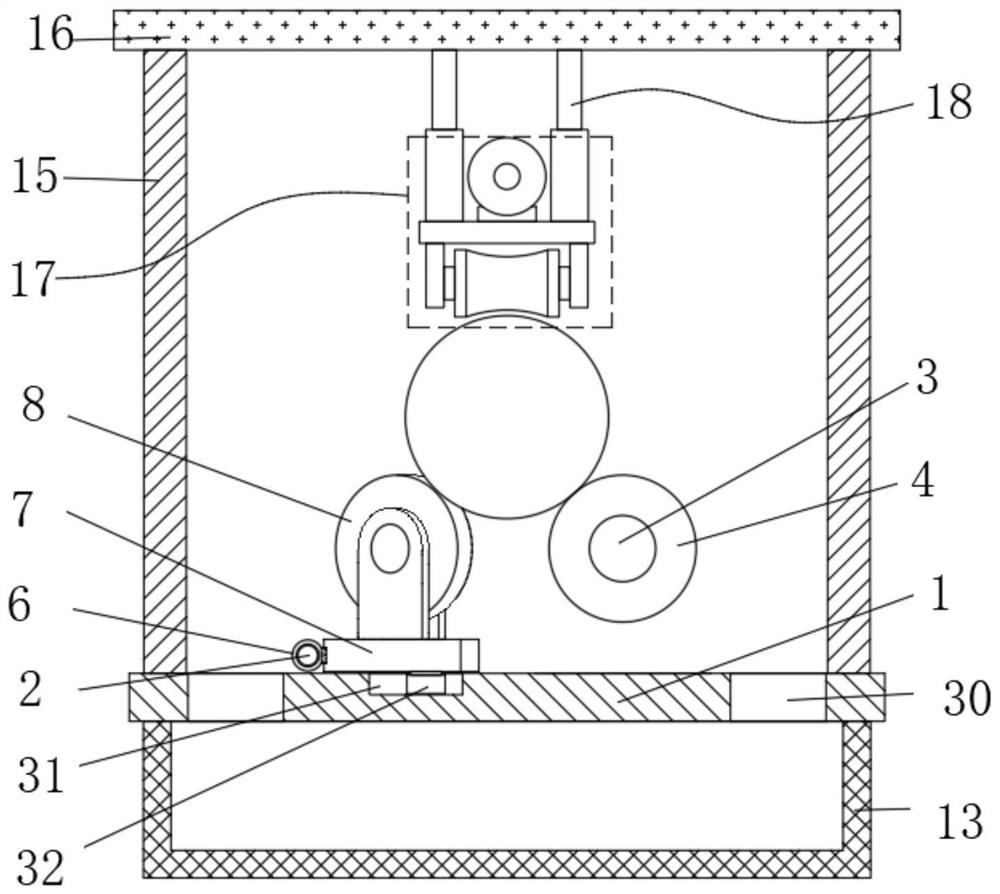

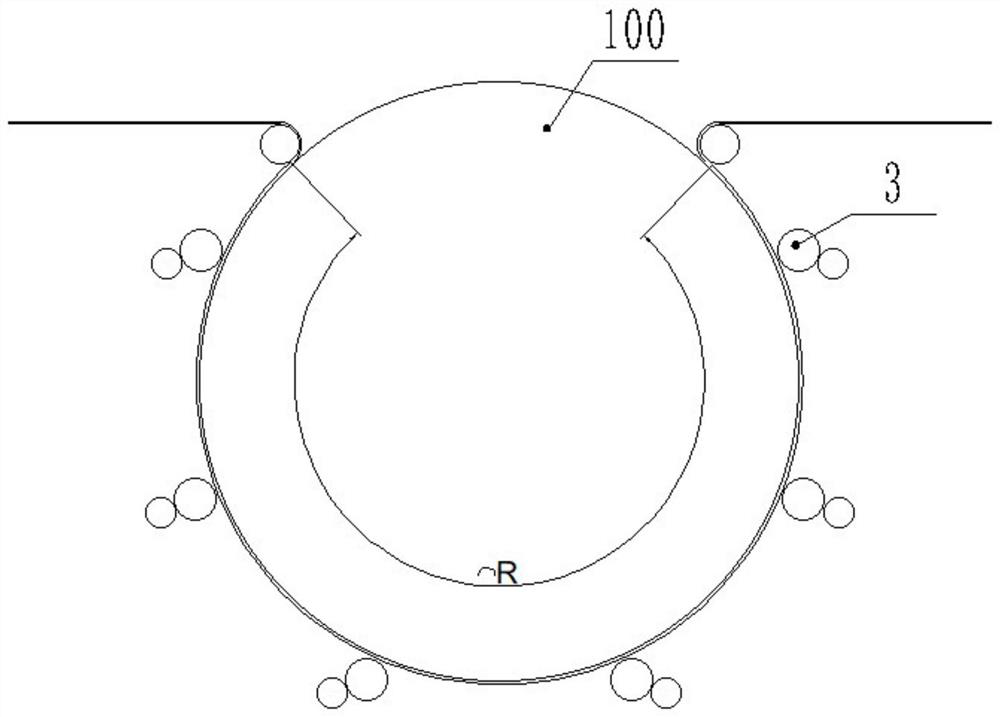

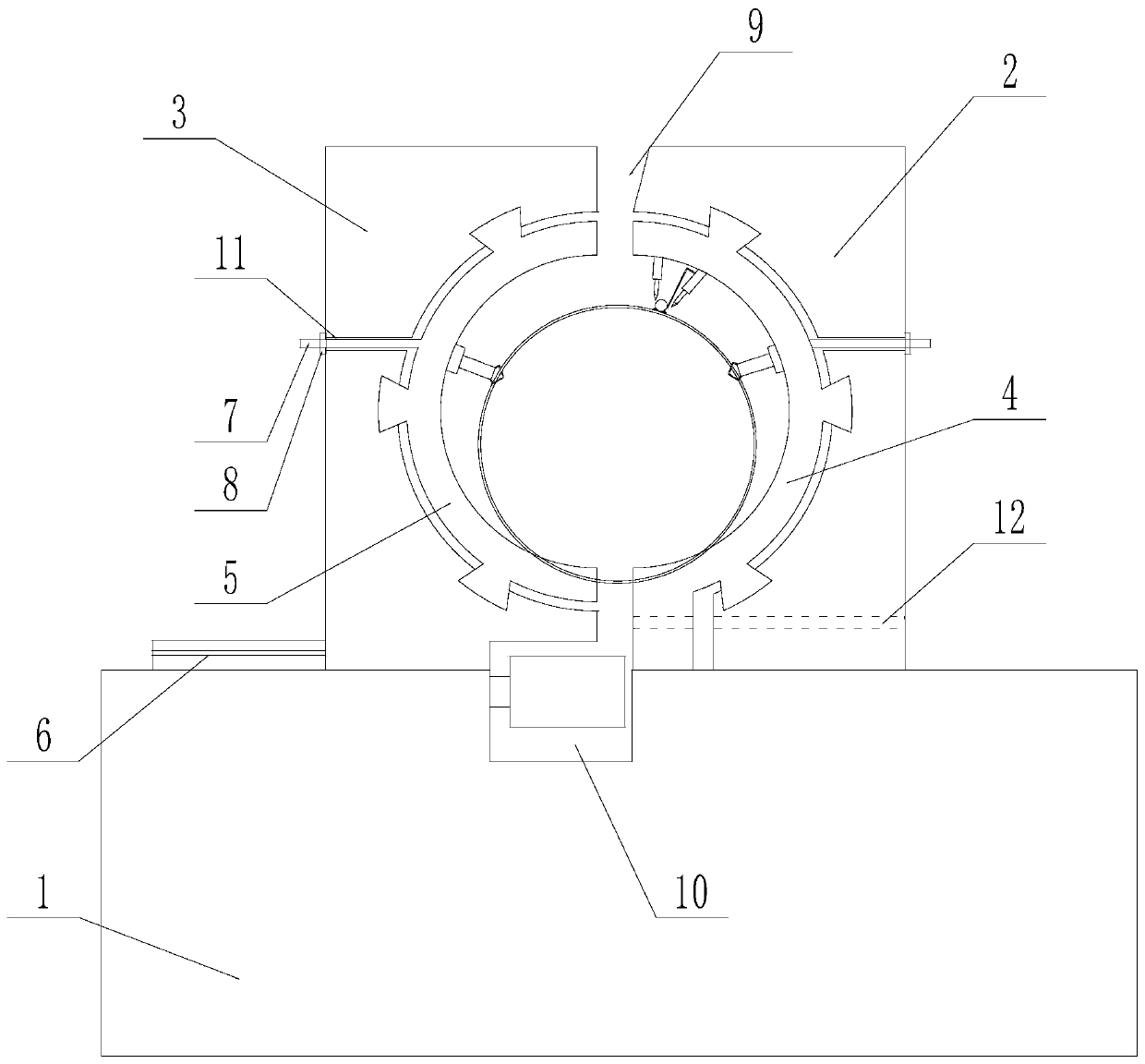

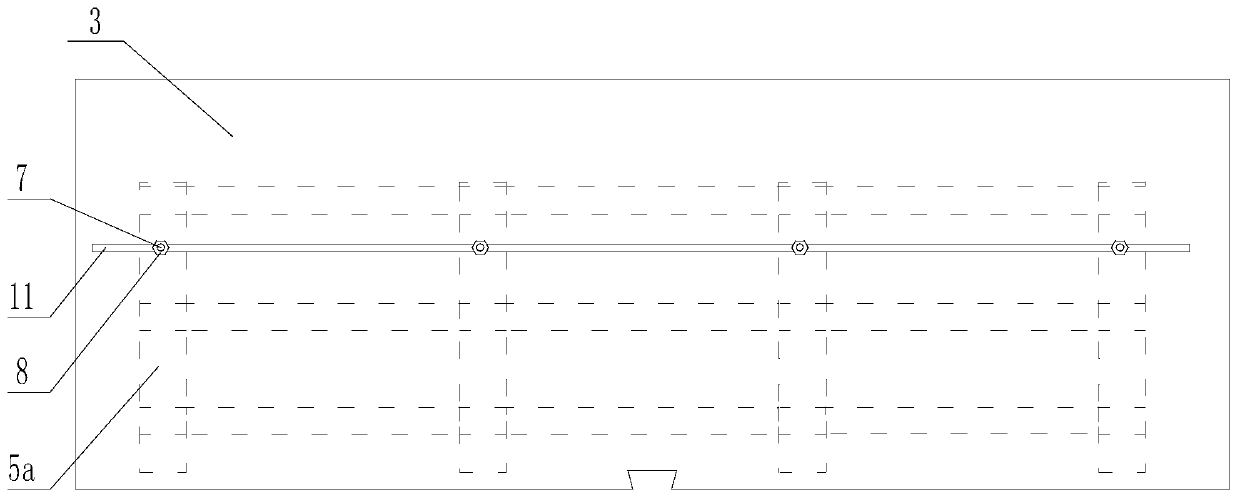

Reinforcing cage stirrup forming device

The invention discloses a reinforcing cage stirrup forming device comprising a base and a mounting seat disposed on the base; an arc-shaped support arm is connected to the upward side of the mountingseat, and the mounting seat is provided with a rolling circle assembly; the rolling circle assembly comprises two mutually parallel fixed rollers which are arranged horizontally, and a movable adjusting roller is arranged in parallel between the two fixed rollers; and the base or the mounting seat is provided with an adjusting roller flipping lifting assembly, and the movable adjusting roller is disposed on the adjusting roller flipping lifting assembly. Compared with the prior art, the reinforcing cage stirrup forming device is convenient to operate and stable to operate, the quality of a reinforcing cage is effectively guaranteed, the rotation precision of a stirrup ring is improved, and therefore the diameter requirement of the reinforcing cage is ensured; by changing the output revolving speeds, the conveying speed of rebars is adjusted, and therefore machining of reinforcing cages with various specifications can be realized; and the degree of automation is high, the energy consumption is saved, the labor intensity of workers is reduced, the production efficiency is improved, and the machining cost is low.

Owner:左红

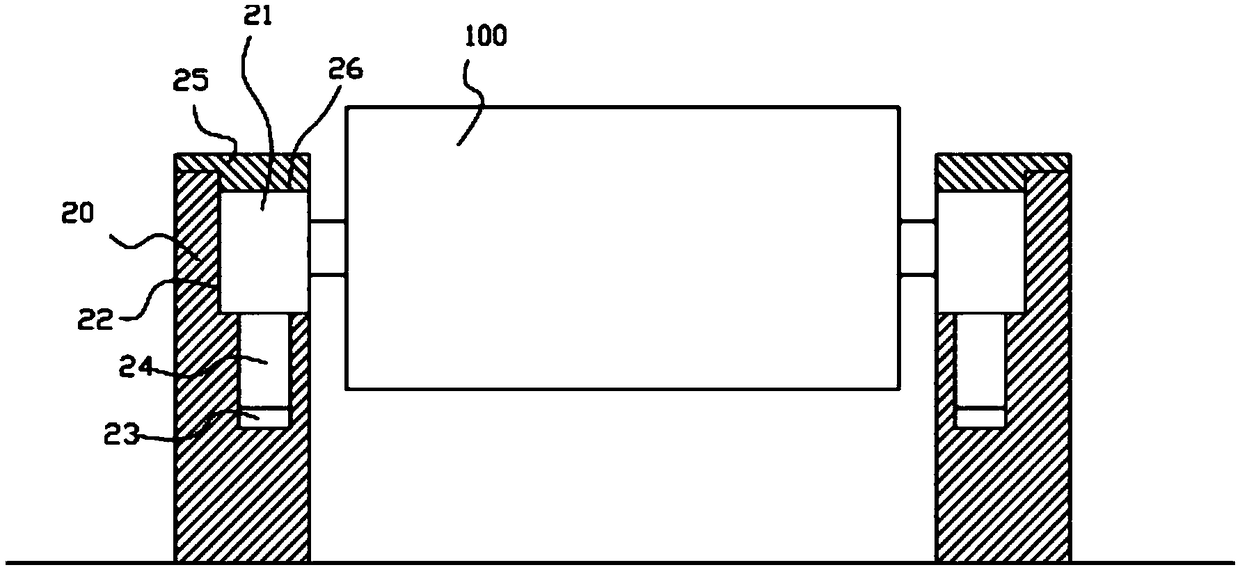

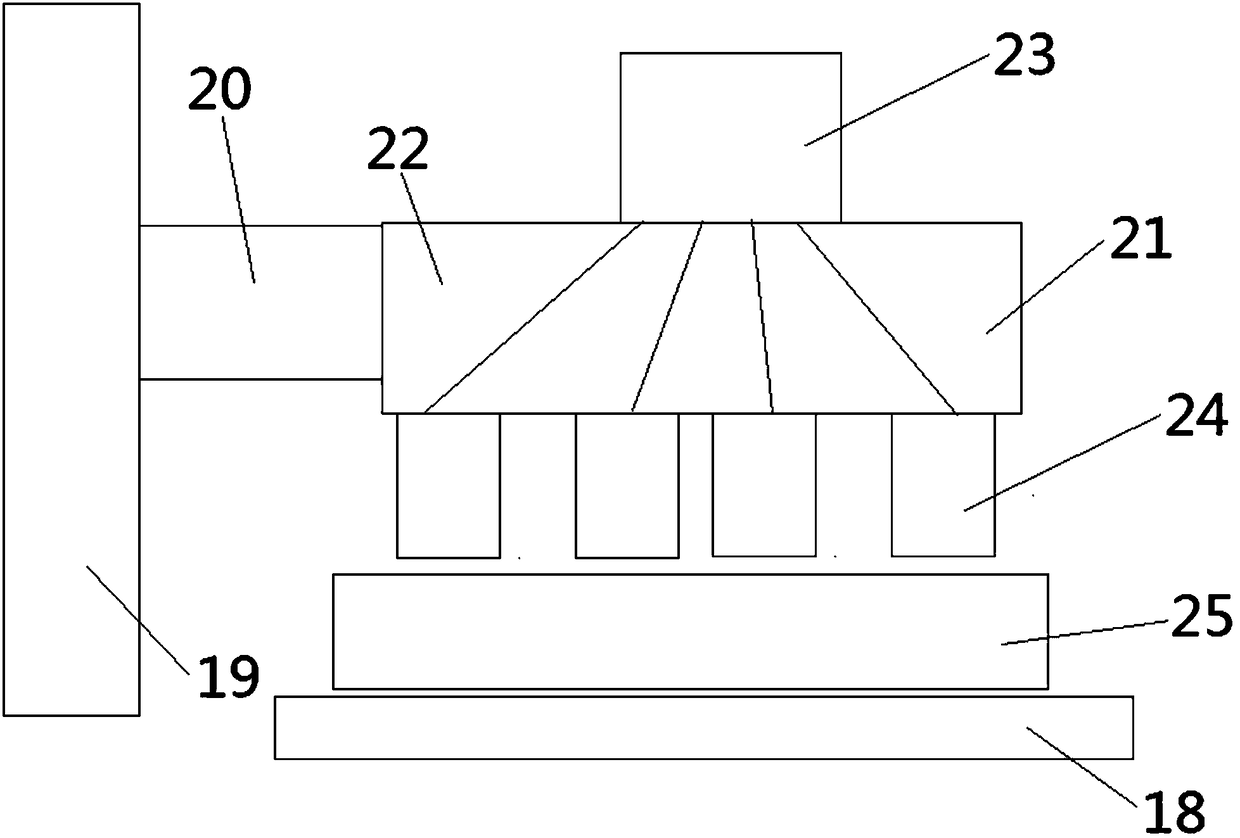

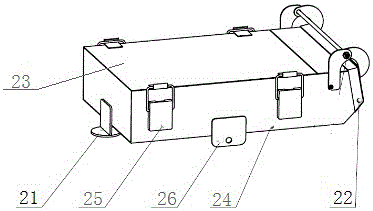

Toothpaste combined loading production line with boxing robot

InactiveCN108298153ASimple structureIncrease productivityPackaging machinesMechanical conveyorsProduction lineToothpaste

The invention provides a toothpaste combined loading production line with a boxing robot. The boxing robot (20) is mounted on a mounting frame (19) of the toothpaste combined loading production line with the boxing robot, a grabbing component (21) is mounted at the tail end of a movable mechanism arm of the boxing robot (20) and comprises a grabbing component body (22) and a vacuum pump (23), anda plurality of suction cups (24) are arranged on the component body (22). Each suction cup (24) is connected with the vacuum pump (23) through a connecting pipe, and the vacuum pump (23) is connectedwith a control component (5). According to the toothpaste combined loading production line with the boxing robot and a toothpaste combined loading production method, the production line is simple in structure, batch automatic combined loading of morning toothpaste and evening toothpaste can be conveniently and rapidly achieved, the combined loading reliability is ensured, the problems of loading omission, excessive loading and wrong loading are avoided, and the toothpaste combined loading efficiency and quality are improved.

Owner:WUHU IROBSYS ROBOT CO LTD

Fodder particle dispensing equipment for livestock raising

InactiveCN107667895AAvoid wastingPrecise deliveryAnimal feeding devicesAvicultureBaseboardLivestock breeding

The invention relates to fodder dispensing equipment, in particular to the fodder particle dispensing equipment for livestock raising. The technical purpose to be achieved is to provide the fodder particle dispensing equipment for livestock raising, by means of the equipment, in a dispensing process, fodder is not wasted and is precisely dispensed, and the fodder dispensing speed can be adjusted.In order to achieve the technical purpose, the invention provides the fodder particle dispensing equipment for livestock raising which comprises a baseboard and first supporting frames; the first supporting frames are symmetrically arranged on the left and right sides of the baseboard, a fodder storage box is arranged between the upper portions of the first supporting frames on the left and rightsides, an auxiliary discharging mechanism is arranged on the top of the rear wall of the fodder storage box, a discharging pipe is arranged on the left side of the bottom of the fodder storage box, and a valve is arranged on the upper portion of the discharging pipe. By means of the fodder particle dispensing equipment for livestock raising, the effects are achieved that in the dispensing process,the fodder is not wasted and is precisely dispensed, and the fodder dispensing speed can be adjusted; by controlling movement of a rack in the leftward direction and the rightward direction, the dispensing speed of fodder particles is controlled, so that it is convenient for a feeder to dispense the fodder particles more precisely.

Owner:刘飞

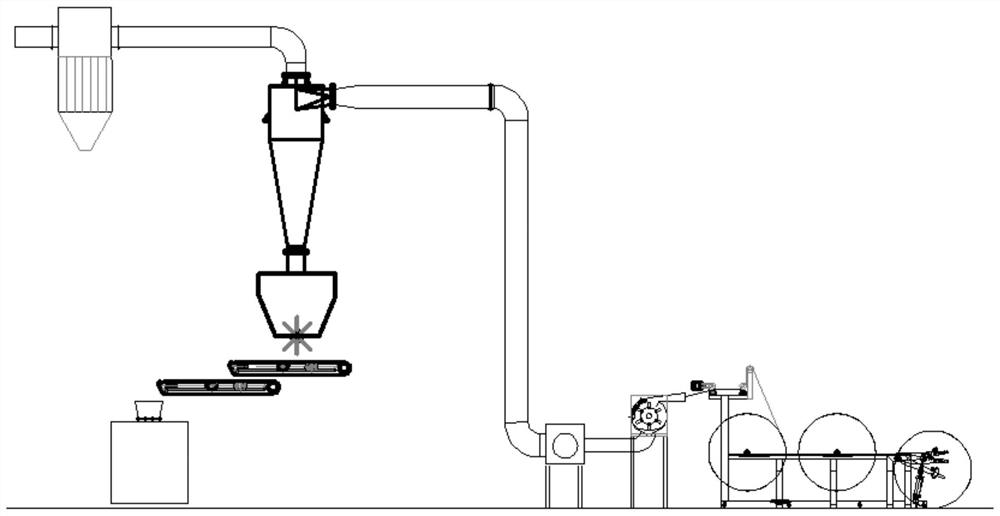

Pulp crushing equipment and method for production of cellulose fiber by solvent method

InactiveCN111841760AGuaranteed crushing effectReduce lossesWeighing apparatus for continuous material flowGrain treatmentsPulp and paper industryCellulose fiber

The invention relates to a pulp crushing equipment and method for cellulose fiber production by a solvent method. The technological process of the pulp crushing method is as follows: pulp is conveyedinto a grinding machine by a feeding system for crushing, and then the crushed pulp is conveyed into a cyclone separator by a conveying fan; and wind and the crushed pulp are separated by the cycloneseparator, the wind is sent into an exhaust channel and treated by a recovery system, and the pulp separated from the wind enters a storage and metering system. The pulp crushing equipment completes the quantitative feeding, crushing, conveying, storage and metering of the pulp through the feeding system, the grinding machine, a conveying system and the storage and metering system. The effect of pulp crushing can be ensured, the degree of pulp crushing after crushing by the grinding machine is 5-200g / L, and all requirements for cellulose fiber production by the solvent method (NMMO) is met. Meanwhile, the recovery system is added, so the loss of pulp powder with low degree of crushing is minimized in the process of conveying and mixing, and the loss is less than 0.01%.

Owner:唐山三友远达纤维有限公司

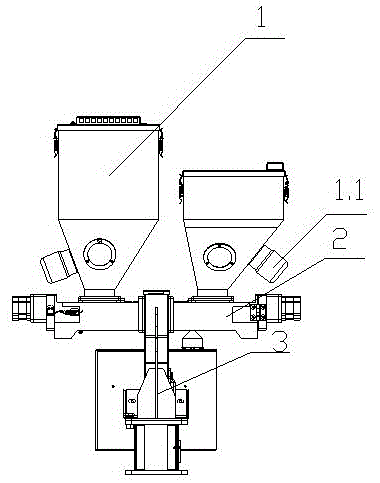

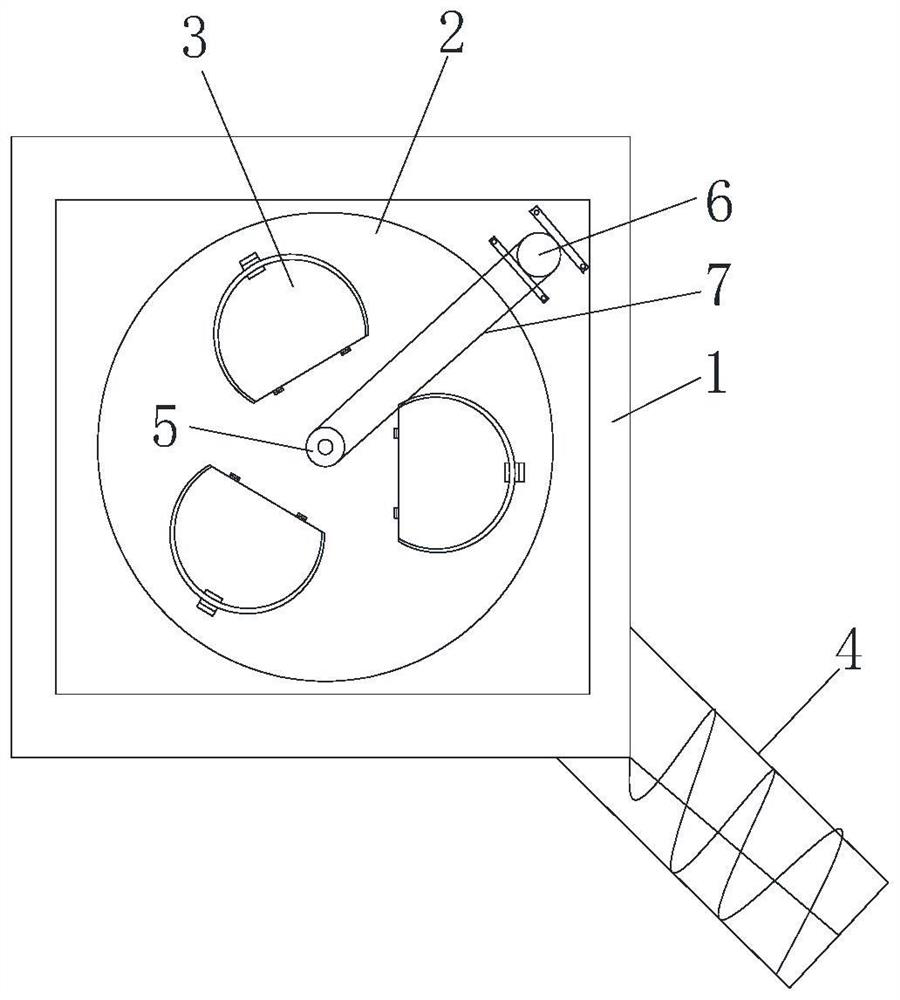

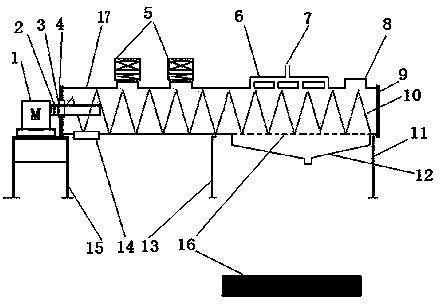

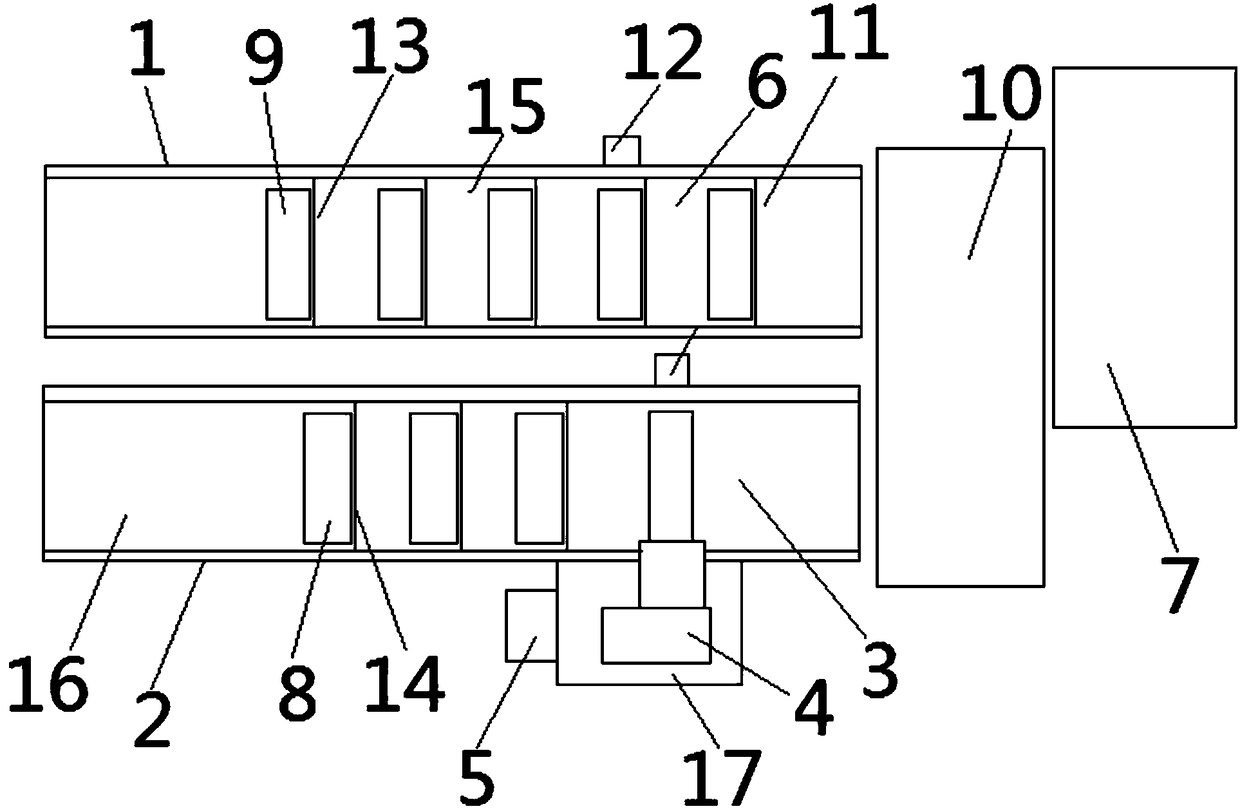

Material mixing control method based on spiral conveying type color master mixing device

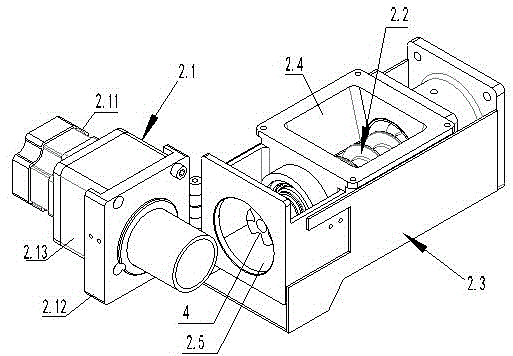

The invention discloses a material mixing control method based on a spiral conveying type color master mixing device. The spiral conveying type color master mixing device comprises hoppers (1), material conveying mechanisms (2) and a material box (3). The hoppers (1) and the material conveying mechanisms (2) are installed in a one-to-one correspondence mode. The material conveying mechanisms (2) are installed on the material box (3). Feeding inlets corresponding to the material conveying mechanisms (2) are formed in the material box (3). Materials mixed through the color master mixing device are conveyed to an injection molding machine to be subjected to melting injection molding, and thus an injection molding product is obtained. The color master mixing device further comprises an image recognition system. An image of the injection molding product is input and the colors of the image are recognized by the image recognition system, and the conveying speed of the material conveying mechanisms is adjusted according to the comparison result. According to the material mixing control method based on the spiral conveying type color master mixing device, the image recognition technology is introduced, negative feedback is added, the comparison result is used for controlling the material conveying speed of the material conveying mechanisms, and thus products of which the color is consistent with that of an expected standard are obtained.

Owner:宁波斯曼尔电器有限公司

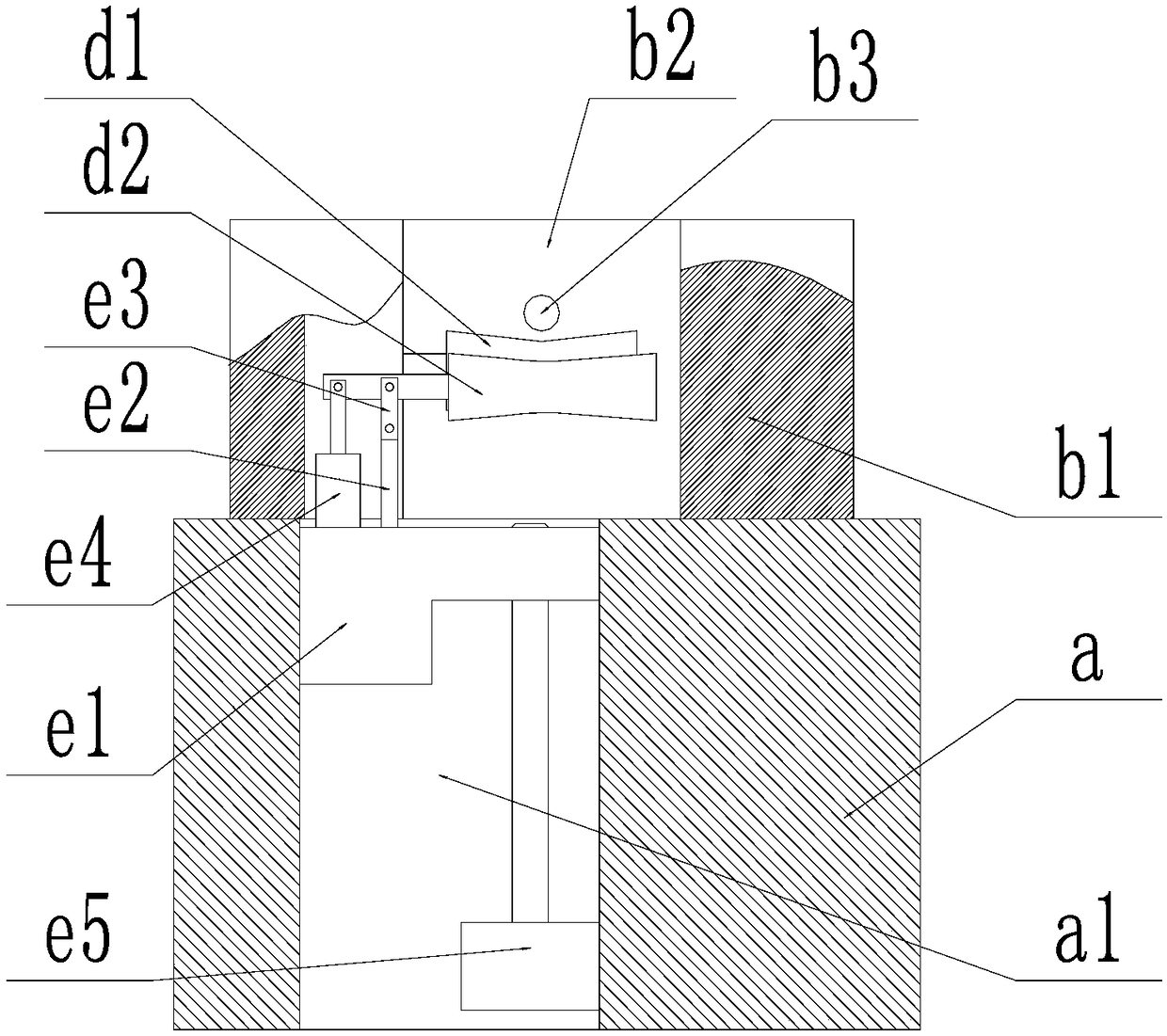

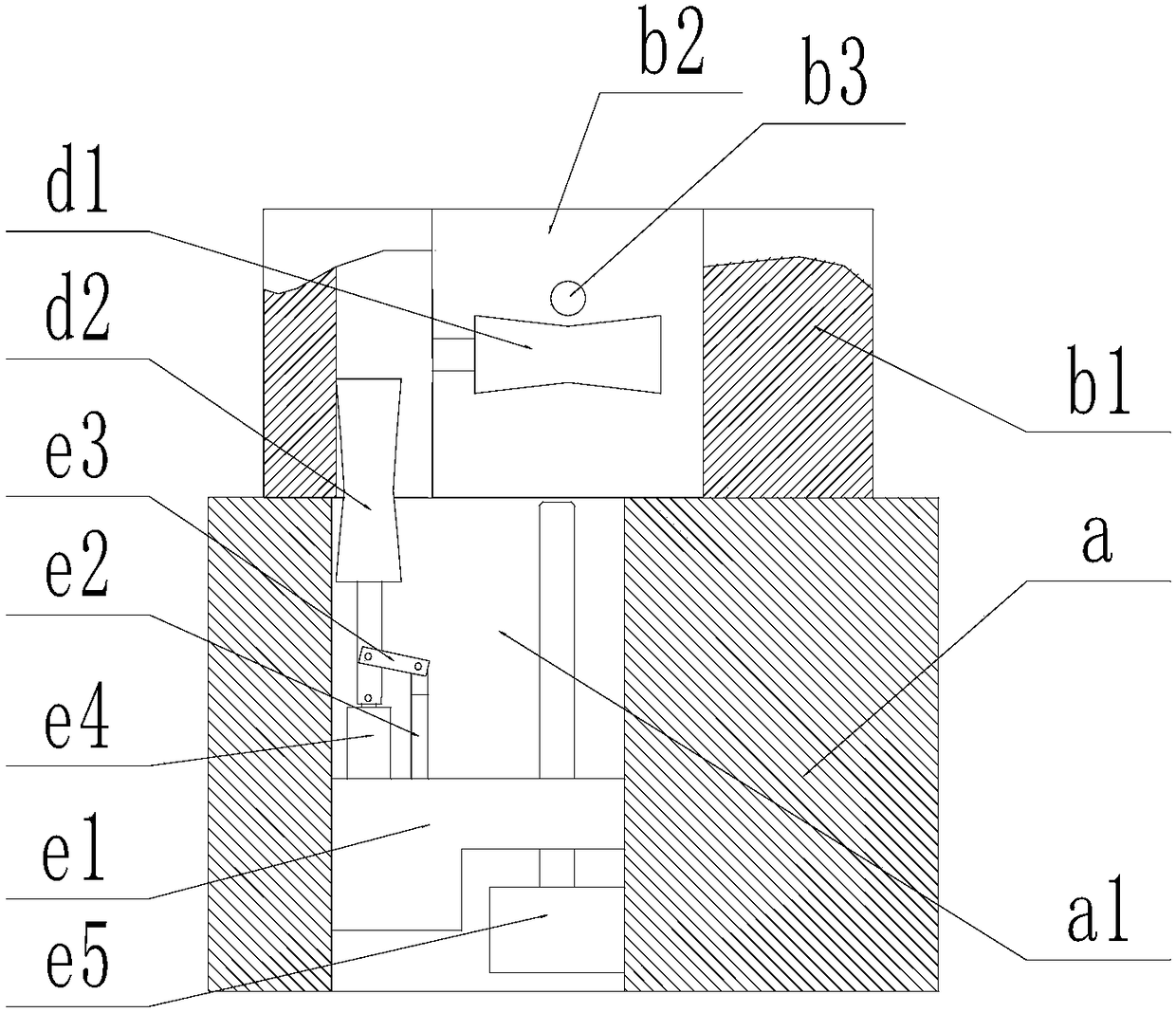

Tea leaf enzyme deactivating pot capable of timely separating tea leaves adhered to each other

PendingCN110742141AAvoid uneven heatingQuality improvementPre-extraction tea treatmentElectric machineryEngineering

The present invention provides a tea leaf enzyme deactivating pot capable of timely separating tea leaves adhered to each other and relates to the technical field of tea leaf enzyme deactivating. Thetea leaf enzyme deactivating pot capable of timely separating the tea leaves comprises a base seat, a top end of the base seat is fixedly provided with a heating cylinder, an inside of the heating cylinder is rotatably connected with a roller, a periphery of a right side of the roller is fixedly provided with a gear, a bottom part of the gear is in a transmission connection with a first motor, a heat conduction chamber is arranged inside the heating cylinder, and a boiler is arranged inside the base seat. During a rolling process of the roller and through up and down shaking of shaking plates,the tea leaf enzyme deactivating pot capable of timely separating the tea leaves adhered to each other can pat the tea leaves of a top side loose, avoids uneven heating of the tea leaves due to adhesion, improves quality of enzyme deactivating, can enable putting amount of the tea leaves to keep a uniform speed, can carry out stable regulation on the putting amount of the tea leaves, and enablesan enzyme-deactivating degree of the tea leaves to be more even.

Owner:遂川县安村茶厂(有限合伙)

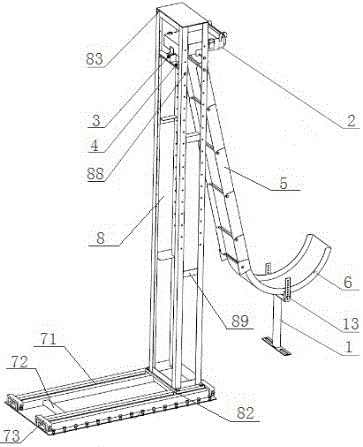

Special test device of ice ingestion of turboprop engine

The invention provides a special test device of ice ingestion of a turboprop engine. The device comprises a support, an ice feeding track, a moving adjustment support, a heat insulation box, an electromagnet and a horizontal support plate. The moving adjustment support comprises a horizontal moving track and an adjustment support. The angle between the ice feeding track and the adjustment support can be changed by moving the adjustment support along the horizontal moving track, so that the feeding speed and angle of ice blocks can be adjusted. Balance and inclination of the heat insulation box is controlled by connection and disconnection of current inside the electromagnet. Furthermore, a plurality of screw holes are arranged in the adjustment support to adjust the heights of the ice feeding track, the heat insulation box and the electromagnet. A plurality of screw holes are arranged in the support for fine adjustment of the height of the ice feeding track. A straight track of the provided ice feeding track is composed of a plurality of segments, so that the height of the ice feeding track can be adjusted. The device can conduct coarse adjustment and fine adjustment of the included angle between the ice feeding track and the adjustment support either horizontally or vertically. The structure is simple, the production cost is low, the adjustment method is smart and flexible, the adjustment range is wide, and the adaptability is high. The device can quickly and easily control the ice feeding speed and angle.

Owner:CHINA AVIATION POWER MACHINE INST

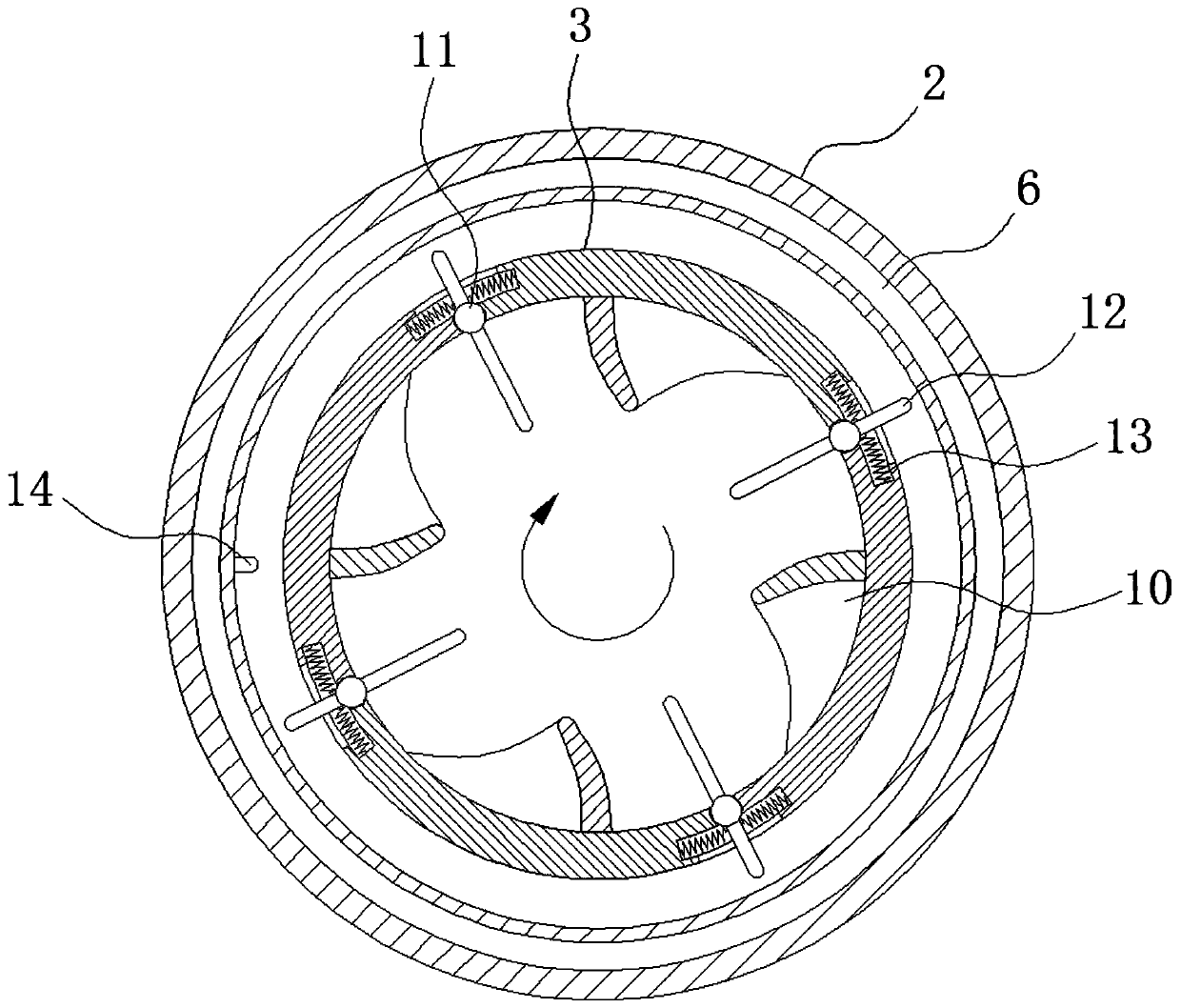

Speed change device for full-automatic color carton production line

PendingCN112610663ASimple structureReduce manufacturing costConveyorsToothed gearingsElectric machineryEngineering

The invention discloses a speed change device for a full-automatic color carton production line. The device comprises a carton body, a speed change mechanism is arranged in the carton body, and the speed change mechanism extends out of the carton body; and the speed change mechanism comprises a motor, the motor is fixedly arranged on one side of the box body, the motor is fixedly connected with a rotating rod through an output shaft, the rotating rod is arranged on one side of the box body and extends into the box body, a square rod is arranged on one side of the rotating rod, and the square rod is connected with the rotating rod through a one-way bearing. According to the device, through the design of the speed change mechanism, the rotating speeds of a connecting rod can be different through meshing of a first gear and a fourth gear and meshing of a second gear and a third gear, then the rotating speeds of a belt wheel are different, and the conveying speed of a conveying belt connected with the belt wheel can be adjusted; and meanwhile the device is relatively simple in structure, the production cost is reduced, so that the use is convenient for a user.

Owner:贵州新邦羽包装有限公司

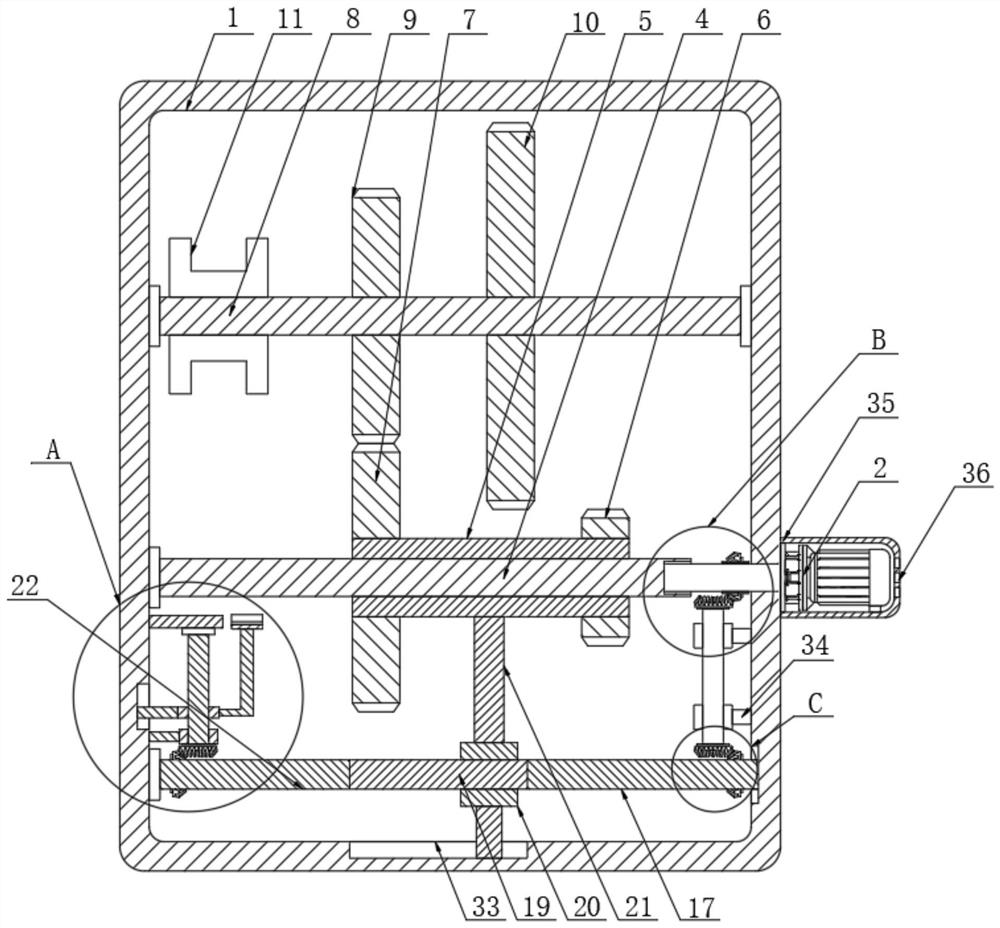

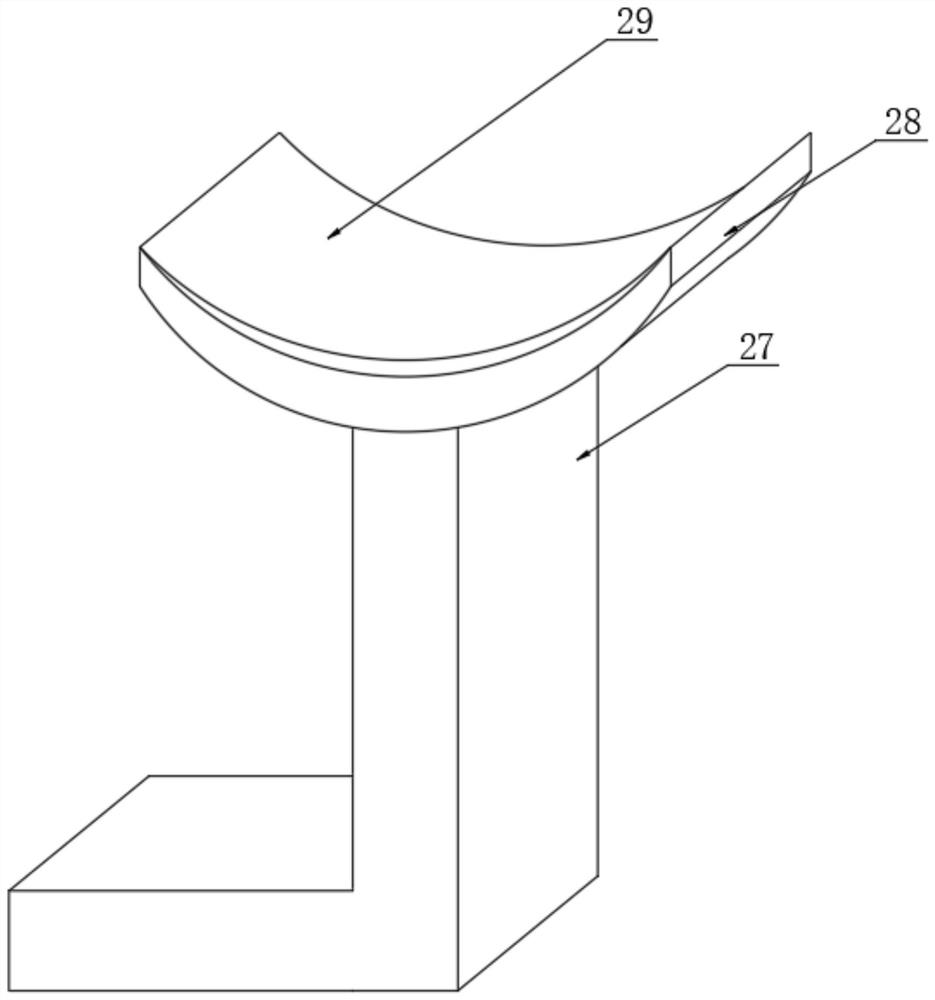

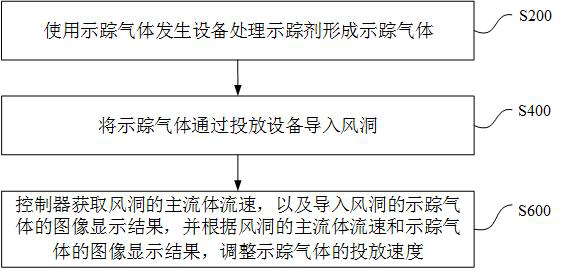

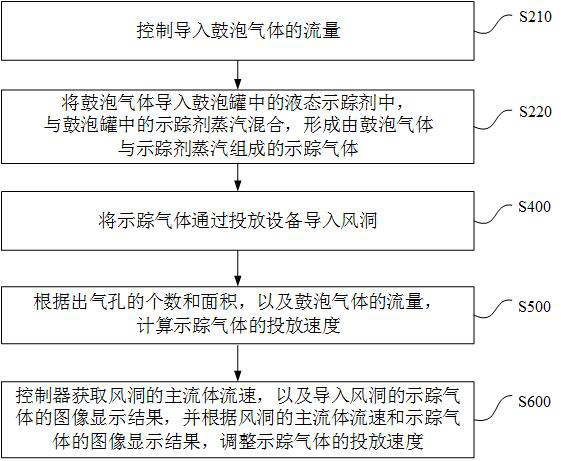

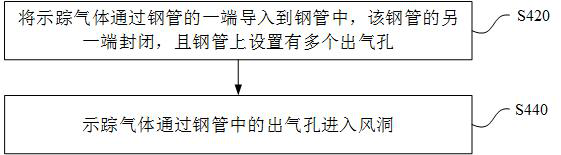

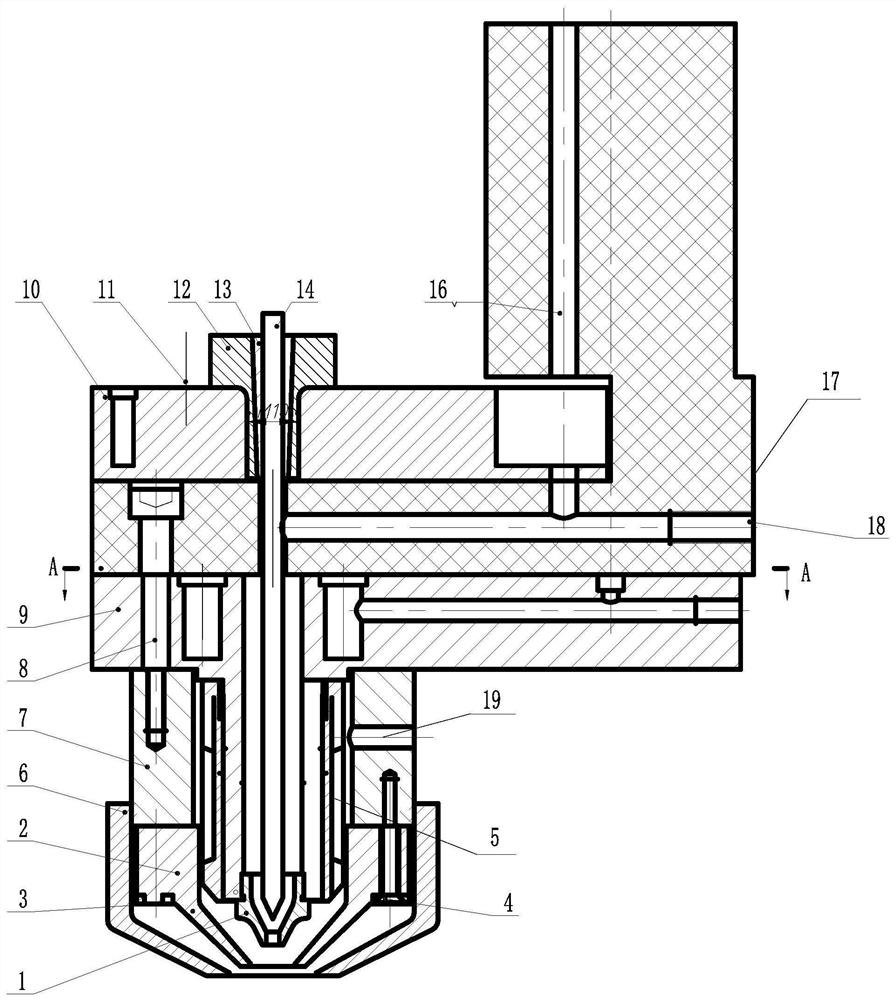

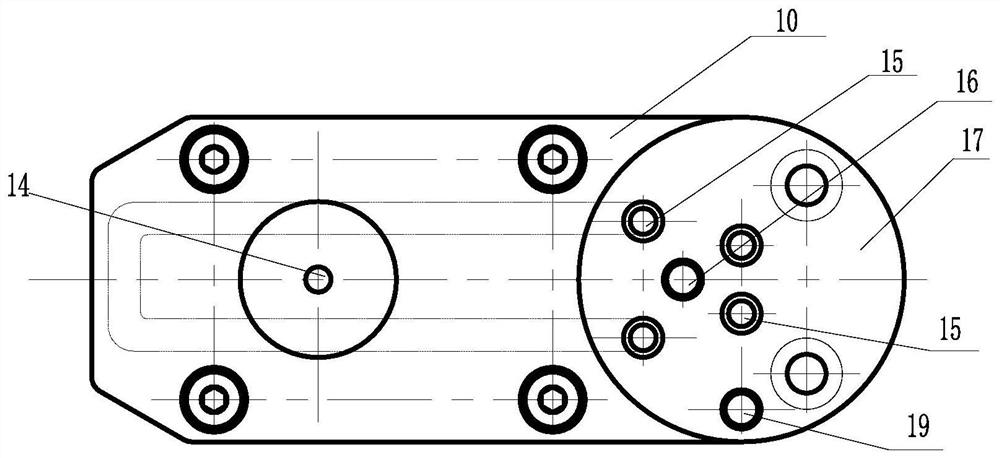

Tracer gas releasing method and device and tracer system

ActiveCN112924135AAdjust delivery speedRealize flow field visualizationAerodynamic testingNuclear energy generationEngineeringMechanics

The invention relates to a tracer gas releasing method and device and a tracer system, and the tracer gas releasing method comprises the steps: a PLIF tracer agent is treated by using tracer gas generation equipment to form tracer gas; the tracer gas is guided into a wind tunnel through the releasing equipment; a plurality of air outlet holes are formed in the leeside of the releasing equipment; and a controller obtains the main fluid flow velocity of the wind tunnel and the image display result of the tracer gas introduced into the wind tunnel, and adjusts the release speed of the tracer gas according to the main fluid flow velocity of the wind tunnel and the image display result of the tracer gas. According to the tracer agent releasing method, PLIF tracer agent steam is used, and wind tunnel flow field visualization can be achieved; a plurality of air outlet holes are formed in the leeside, so that a plurality of tracing lines can be formed, the visual range is expanded, and more flow field information is obtained; and according to the main fluid flow velocity of the wind tunnel and the image display result of the PLIF tracer introduced into the wind tunnel, the release speed of the PLIF tracer is adjusted, and the stability of the tracing effect is improved.

Owner:SHENYANG UNIV

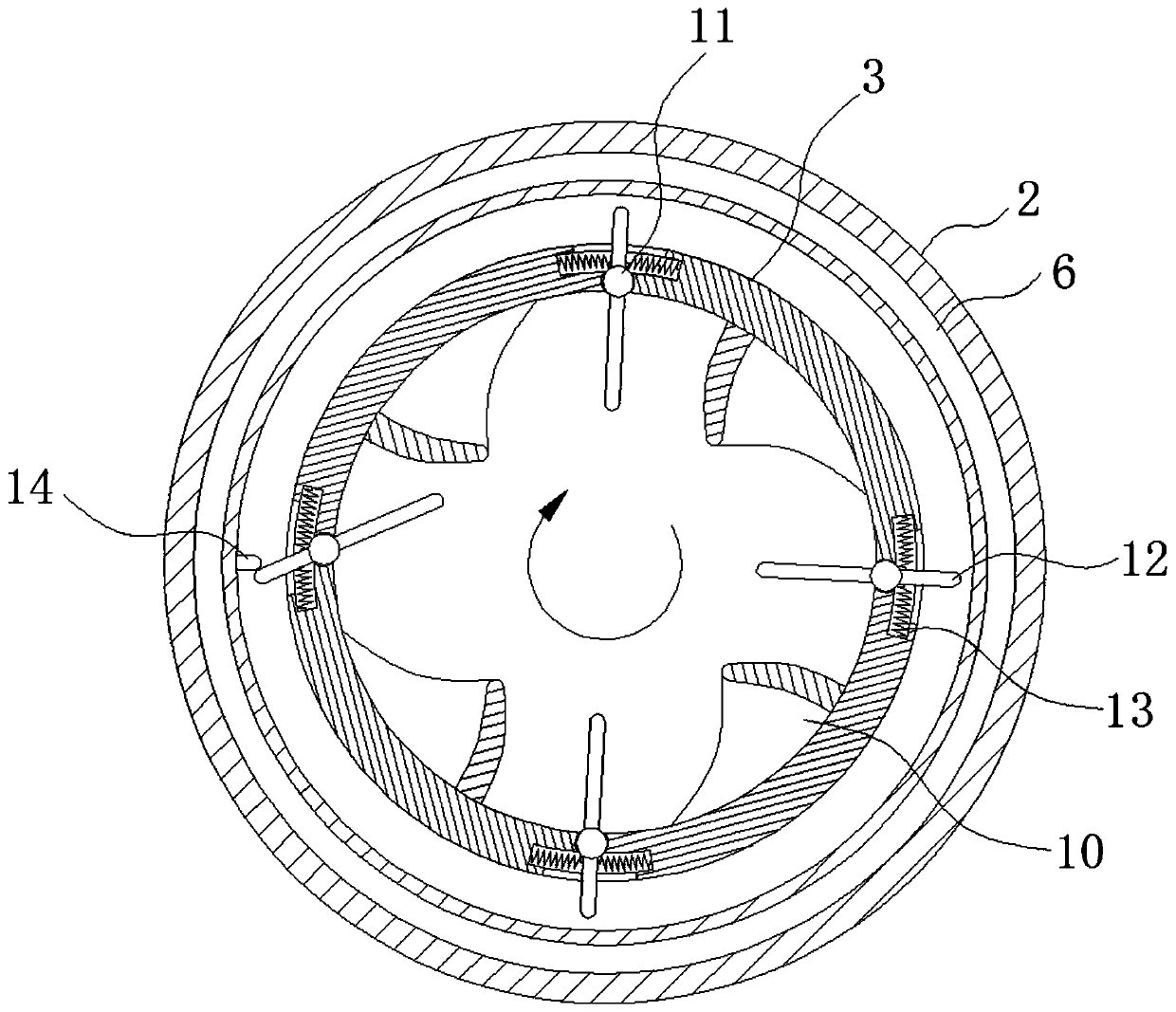

Circumferential powder feeding type plasma generator

PendingCN111970808AImprove molding qualityOptimize locationPlasma techniqueSpray discharge apparatusPlasma generatorMechanical engineering

The invention discloses a circumferential powder feeding type plasma generator. The circumferential powder feeding type plasma generator comprises a nozzle, a lower gun body and an upper gun body, thelower gun body and the upper gun body are connected with an insulating block; a tungsten electrode penetrates through a tungsten electrode seat and extends to the lower part of the lower gun body; the tungsten electrode seat is fixed on the upper gun body through a fixing seat, and the tungsten electrode can move up and down relative to the lower gun body; the nozzle is arranged under the bottomend of the tungsten electrode, and a plasma torch chamber is arranged between the lower gun body and the nozzle; a powder distributor is connected with the upper gun body and the lower gun body, and the lower part of the powder distributor is connected with the nozzle; the powder distributor is communicated with a powder feeding pipe, and the powder feeding pipe is fixedly arranged on a powder blocking device; a powder feeder is arranged under the powder distributor, the powder feeder is communicated with the powder distributor, and the powder blocking device is arranged between the powder feeder and the bottom of the lower gun body; and outer covers are arranged outside the powder feeder and the powder second clamping parameter. By means of the optimized design of the powder distributor and the powder feeder, it is guaranteed that alloy powder is continuously fed into the plasma torch according to the preset proportion, the coating forming quality is improved, and the nozzle blockagephenomenon is avoided.

Owner:南通德邦新材料科技有限公司

Quantitative-proportioning feeding device for feed processing

PendingCN114803552ASave time at workImprove refinementLarge containersLoading/unloadingElectric machineryControl theory

The invention relates to the technical field of feeding devices, in particular to a quantitatively-proportioned feeding device for feed processing, which comprises a mounting frame body, the rotating disc is arranged on the mounting frame body in a rotatable manner; the plurality of charging funnels are arranged on the rotating disc in a circumferential array manner; and the guide device is arranged below the mounting frame body and is used for conveying the feed in one of the loading hoppers. Different types of feed are added into the charging hoppers, the movable motor drives the rotating disc to rotate to drive the charging hoppers to rotate, the corresponding charging hoppers are rotated to the positions above the guide-in parts of the guide devices, the electronic valves below the charging hoppers are opened, and the feed in the hoppers is conveyed into the guide-in parts and then conveyed to other stations through the guide devices to be processed. The working time of operators is shortened, refined and programmed management is facilitated, and misoperation is avoided.

Owner:南京宝辉生物饲料有限公司

Trunk peeling device for furniture production and use method thereof

PendingCN114523399AAvoid roundnessAdjust the tilt angleEdge grinding machinesRevolution surface grinding machinesTree trunkScrew thread

The invention discloses a trunk peeling device for furniture production, which comprises a workbench, a threaded rod and a mounting shaft are respectively arranged on two sides of the upper surface of the workbench, and a plurality of rollers which are horizontally distributed at equal intervals fixedly sleeve the outer side wall of the mounting shaft; the outer sides of the two ends of the mounting shaft and the outer sides of the two ends of the threaded rod are movably sleeved with positioning blocks through bearings, and one side of the threaded sleeve is movably connected with a base through a pin shaft. The invention further discloses a using method of the trunk peeling device for furniture production, and the using method comprises three steps, so that the situation that the trunk is not round enough due to the fact that the single side of the trunk is excessively processed is avoided. The threaded sleeves and the base are movably connected through the pin shafts, the base and the limiting sliding block are movably connected through the rotating shaft, and therefore the multiple threaded sleeves can be driven to synchronously move by rotating the threaded rod, and the effect of adjusting the inclination angle of the conveying wheel is achieved; the trunk conveying speed of the conveying wheels can be adjusted by adjusting the inclination angles of the conveying wheels.

Owner:雷新玲

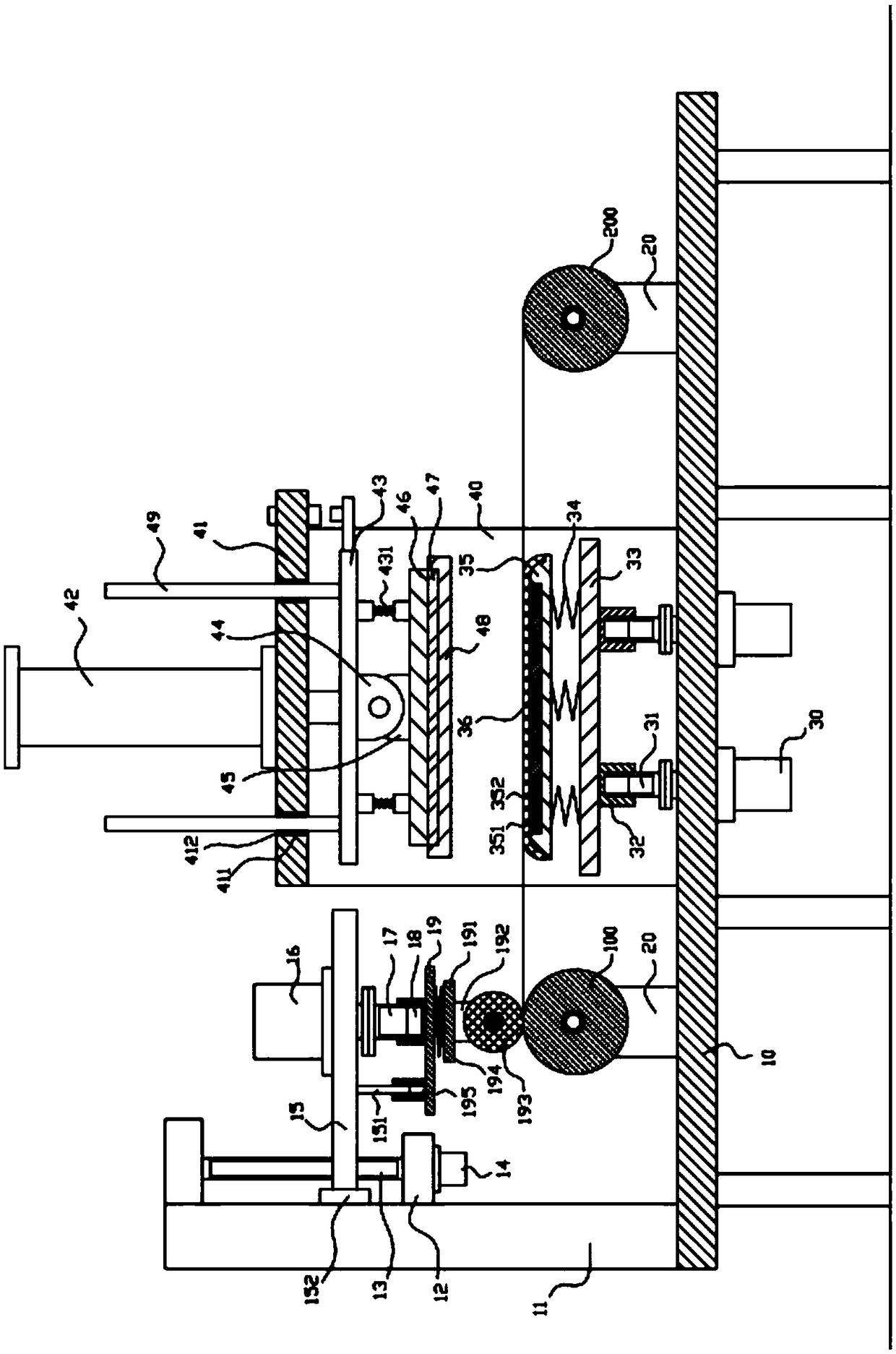

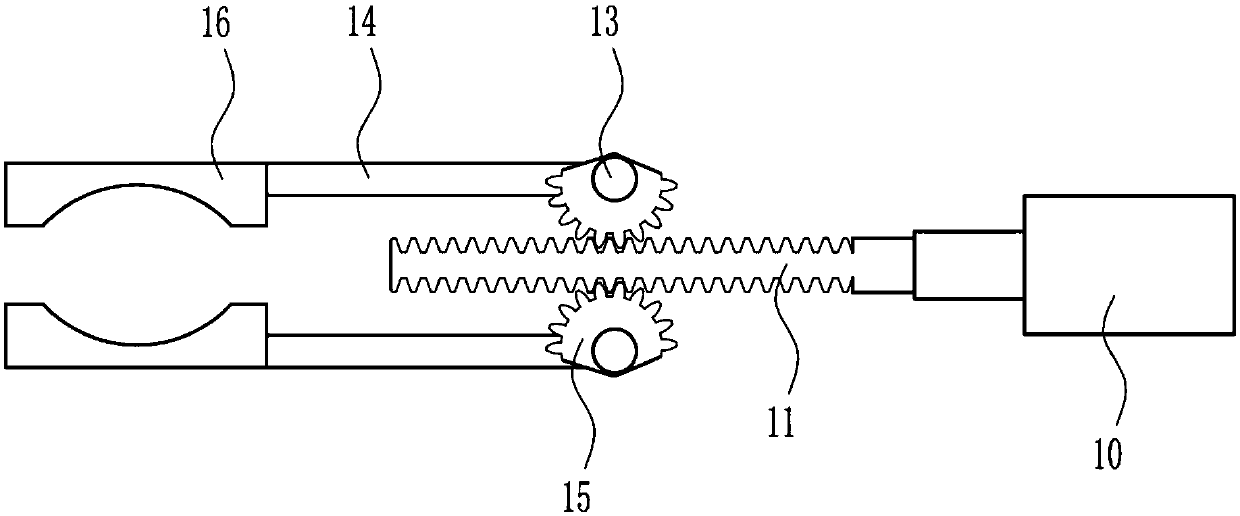

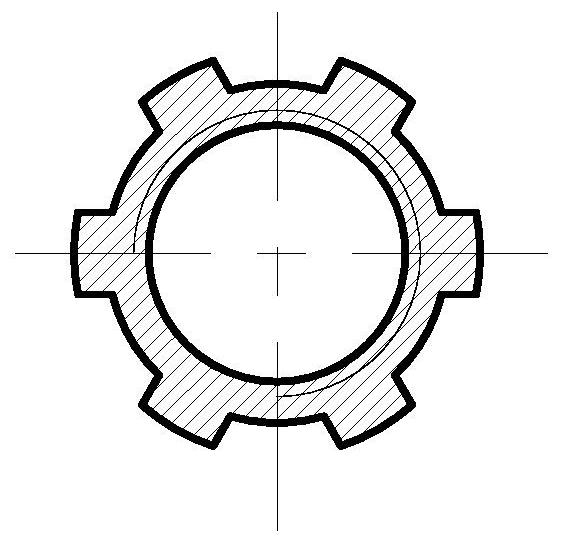

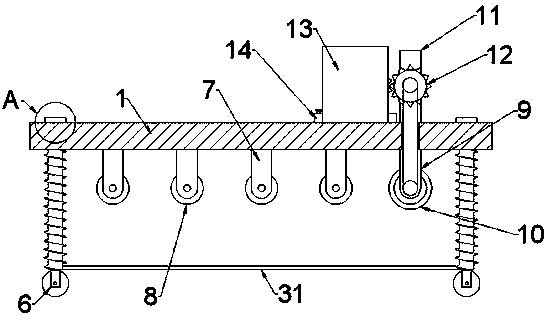

Multi-gear auxiliary conveying device for packaging paper shell production line

InactiveCN110103504AAdjust delivery speedAvoid affecting processingBox making operationsPaper-makingProduction lineGear wheel

The invention discloses a multi-gear auxiliary conveying device for packaging a paper shell production line; the multi-gear auxiliary conveying device for packaging the paper shell production line comprises a beam plate, lifting support structures arranged at the sides of the beam plate to adjust the supporting, a conveying mechanism for assisting the movement of the paper shell and a drive structure for controlling the operation of the conveying mechanism; the lifting support mechanisms at the two sides are synchronously lifted and lowered by the rotation adjustment, and the drive structure drives the conveying mechanism to present different conveying speeds by a sliding method. In the invention, a threaded rod is driven to lift in a rotating sleeve by the rotating sleeve, and the cooperation of a chain wheel and a chain can ensure the lifting synchronization; through adjusting the lifting support structure, the operation of the conveying mechanism can adjust and drive the paper shellto move so as to avoid jumping during the conveying process of the paper shell to affect the processing; through adjusting the different sizes of a first drive gear and a second drive gear in a drivestructure, different speeds can be generated after the transmission gear is matched, so that the conveying speed of the paper shell can be adjusted, and the processing is adjustable and more convenient.

Owner:温州誉诚包装有限公司

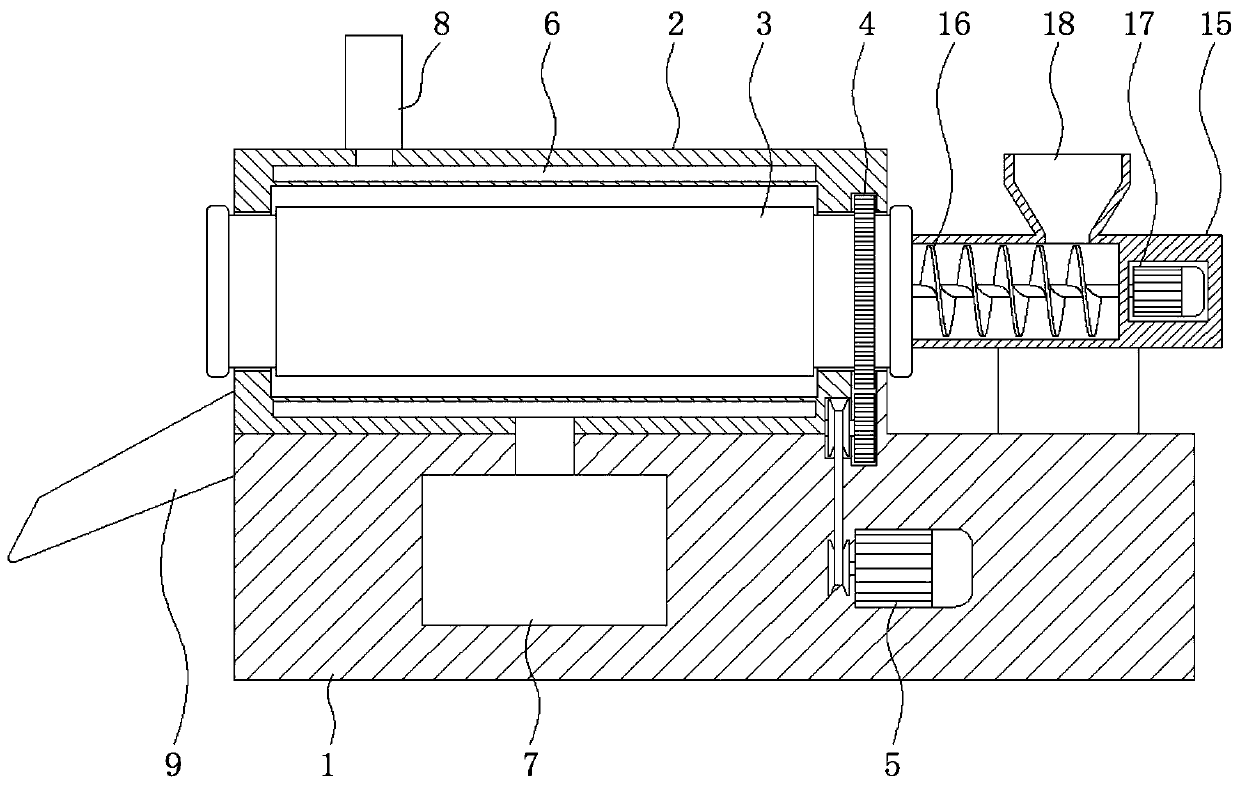

Plastic dewatering and drying machine

PendingCN111421697AAdjust delivery speedAdjust outputDrying gas arrangementsProcess engineeringIndustrial engineering

The invention discloses a plastic dewatering and drying machine which comprises an outer barrel, a dewatering and drying system, a conveying mechanism and a rack. A feeding port is formed on one end of the outer barrel, and a discharging port is formed in the other end of the outer barrel. An air heater and an air pipe are mounted on the upper portion of the outer barrel. A slot screen plate is arranged in the middle of the lower portion of the outer barrel. A short shaft packing auger of the conveying mechanism is mounted in the outer barrel. According to the plastic dewatering and drying machine, conveyed materials are preliminarily dewatered firstly through the air pipe, and then dried through the air heater. The plastic dewatering and drying machine has the advantages of being compactin structure and good in drying effect.

Owner:LUOYANG HEMENG TECH CO LTD

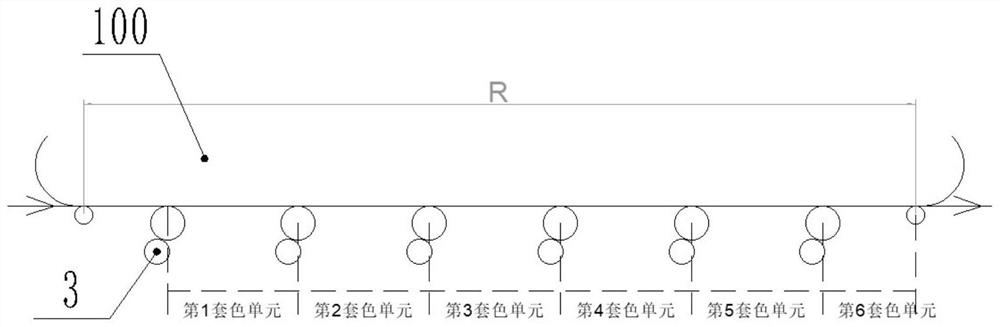

Flexible plate printing machine with accurate color register and control method

ActiveCN113442555AAccurate color registrationAdjust delivery speedRotary letterpress machinesPrinting press partsProcess engineeringPrinting ink

The invention relates to the technical field of flexible package printing, in particular to a flexible plate printing machine with accurate color register. The flexible plate printing machine comprises an unwinding component used for feeding a to-be-printed coiled material; a printing component used for printing ink on a printing material supplied by the unwinding component; a winding component used for winding the printing material printed by the printing component; and a controller, wherein the printing component comprises at least two printing units which are linearly arranged in spatial distribution. The printing units are arranged in a distributed mode, tension isolation roller sets are arranged to limit the change of the tension of the printing materials in the printing units, the output ends of the printing units are connected with tension monitoring components, and the conveying speed of the tension isolation roller sets to the printing materials is adjusted in real time through tension feedback; and the printing materials in each printing unit are controlled to be subjected to transfer printing and color register with the same tension, so that the materials do not deform during color register, and accurate color register in each printing unit is ensured.

Owner:南京邦诚科技有限公司

Production method for toothpaste combination

InactiveCN108248934ARealize automated productionSimple structurePackaging automatic controlPackaging machinesProduction lineToothpaste

The invention provides a toothpaste combination production line and belongs to the technical field of toothpaste production equipment. A control cylinder (4) is arranged at the side surface of the tail end (3) of a late packaging toothpaste conveying line (2) of the toothpaste combination production line. The control cylinder (4) is connected with a control part (5), a combined toothpaste packaging machine (10) is connected with the tail end (6) of an early-packaging toothpaste conveying line, and the combined toothpaste packaging machine (10) is connected with the combined toothpaste collecting box (7). The toothpaste combination production line and the toothpaste combination production method are simple in structure, batch automatic combination of early-packaging toothpaste and late-packaging toothpaste can be conveniently and quickly realized, the reliability of the toothpaste combination is ensured, the problems of less, more and wrong packaging are avoided, and the efficiency of toothpaste combination and the quality of toothpaste combination are improved.

Owner:WUHU IROBSYS ROBOT CO LTD

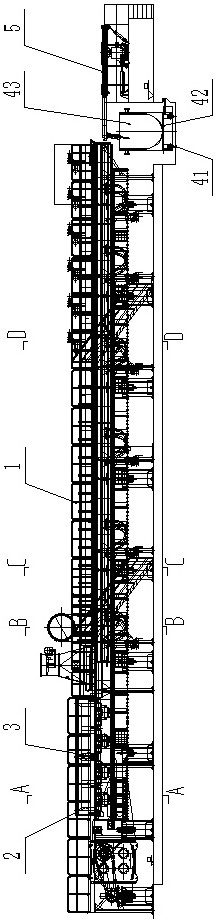

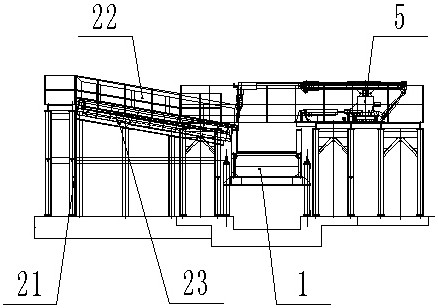

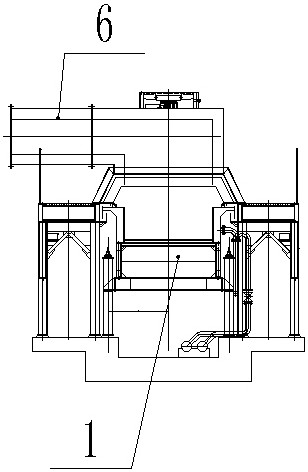

Smelting Production System Based on Continuous Preheating Conveyor

ActiveCN110982978BIncrease incomeSave loading timeManufacturing convertersProcess efficiency improvementFlue gasProcess engineering

The invention discloses a smelting production system based on a continuous preheating conveyor, which comprises a continuous preheating conveyor. There is a transfer conveying line, which is connected to the converter; the continuous preheating conveyor is divided into a preheating section and a heating section in turn along the conveying direction. The preheating section is equipped with a high-temperature flue gas outlet, and the high-temperature flue gas outlet is connected to a preheating recovery device; a burner is arranged in the heating section, and the burner is connected with an air inlet pipe for supplying combustion-supporting air and a gas inlet pipe for supplying coal gas, and the intake air of the air inlet pipe and the gas inlet pipe is preheated by the preheating recovery device. The present invention starts from the feeding of the smelting production system, the transfer of hot materials after preheating, the uniform distribution of materials and the comprehensive recovery and utilization of energy, which greatly shortens the feeding time, improves the transfer efficiency, and realizes the preheating of high-temperature flue gas Recycling, thereby shortening the smelting time and improving production efficiency.

Owner:河南全顺振动设备有限公司

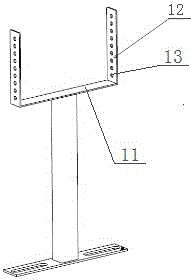

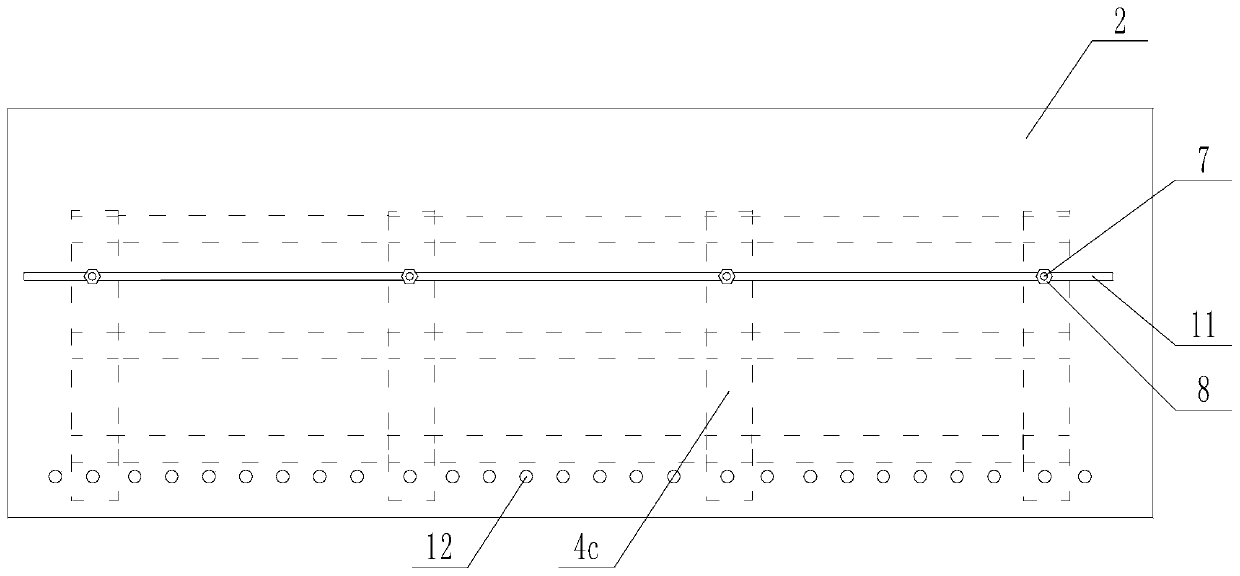

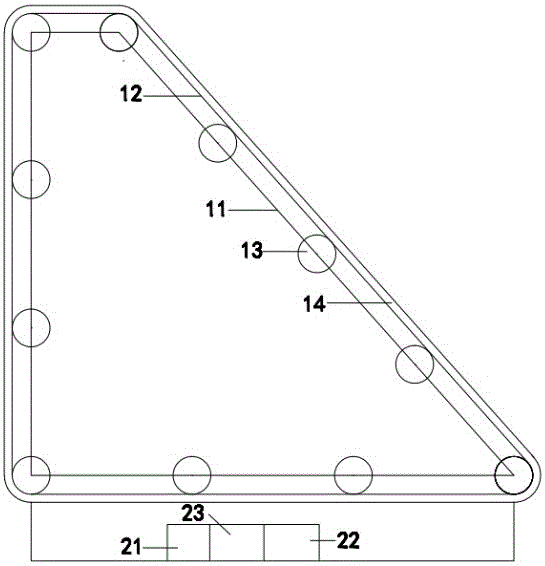

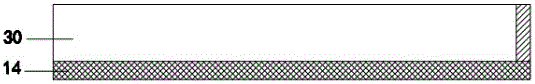

Device with magnetic material for conveying object carriers for synchronizer component arranging table

InactiveCN105984690AEasy to transportEasy to fixConveyorsControl devices for conveyorsControl systemPrism

The invention discloses a transport device for a synchronizer sorting table carrier with magnetic materials, which includes a bracket, two conveyor belts and a control system; the bracket is a prism with a right-angled trapezoidal side; the two conveyor belts are installed On the periphery of the right-angled trapezoid on the side of the prism; the control system includes a motor, a signal receiver and a processor; the motor is connected to the conveyor belt; the motor and the signal receiver are connected to the processor; each A layer of magnetic material is arranged on the conveyor belt. The transportation device provided by the invention has simple structure, convenient operation and strong practicability, and can greatly improve production efficiency.

Owner:路惠忠

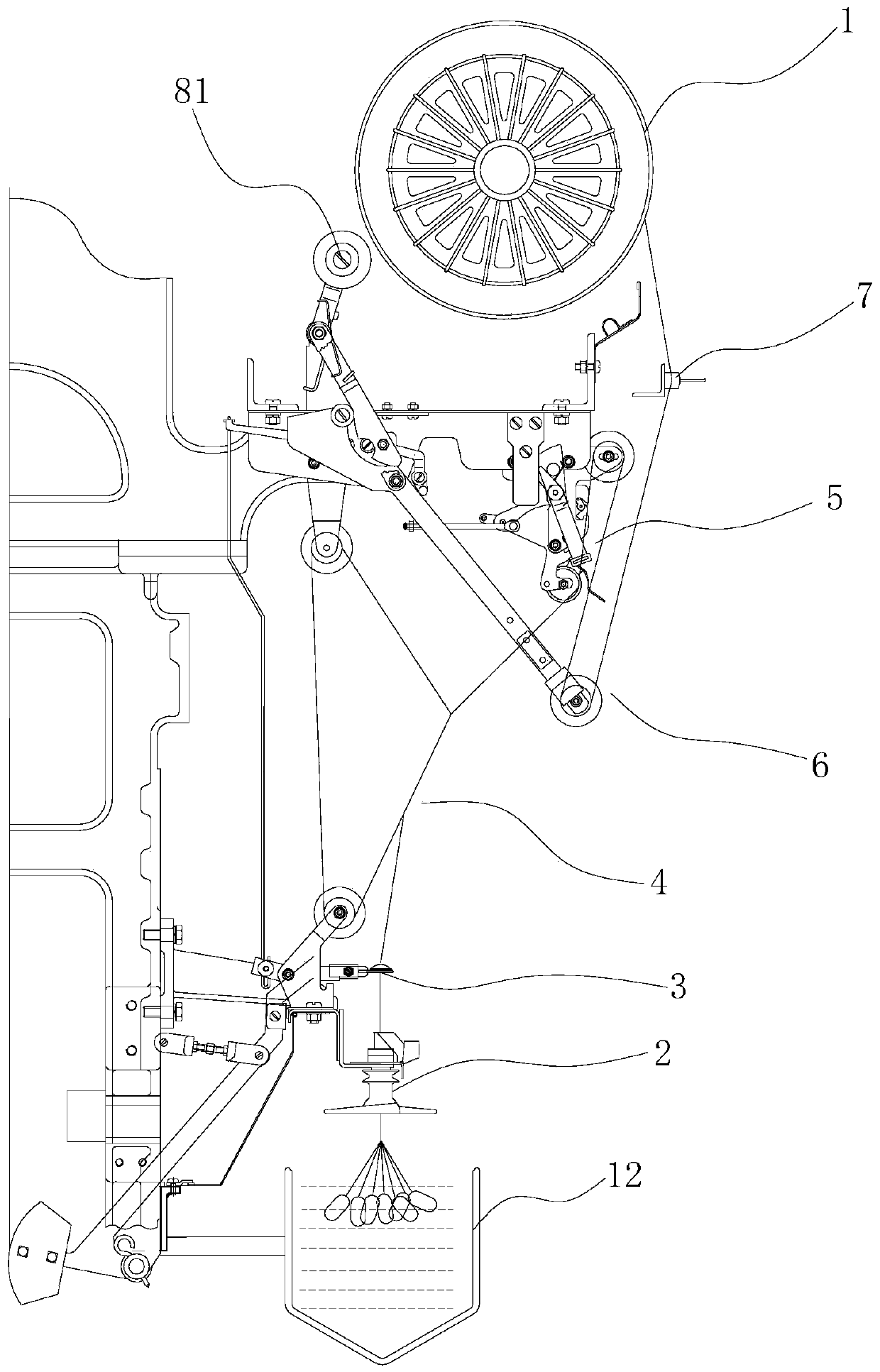

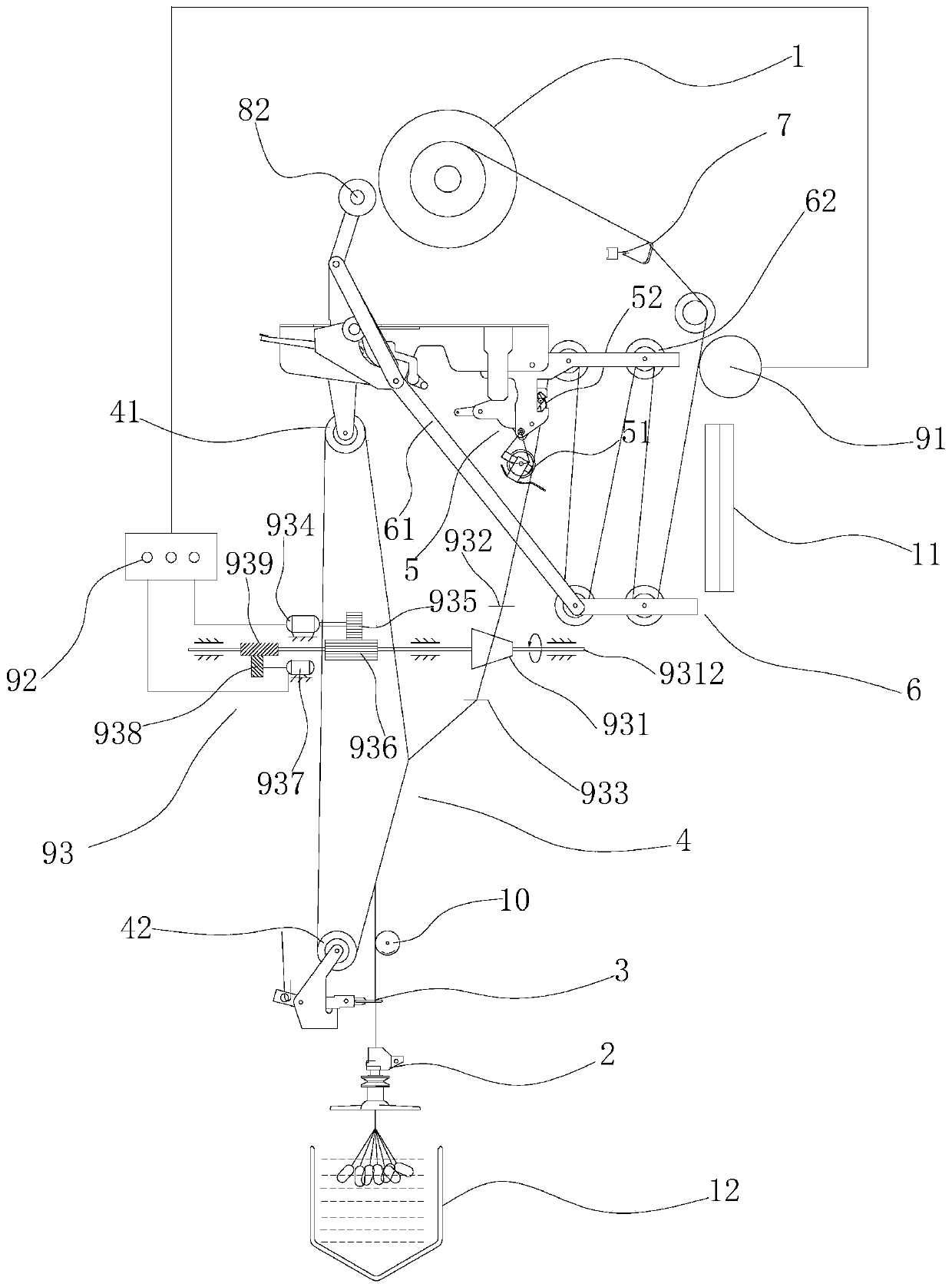

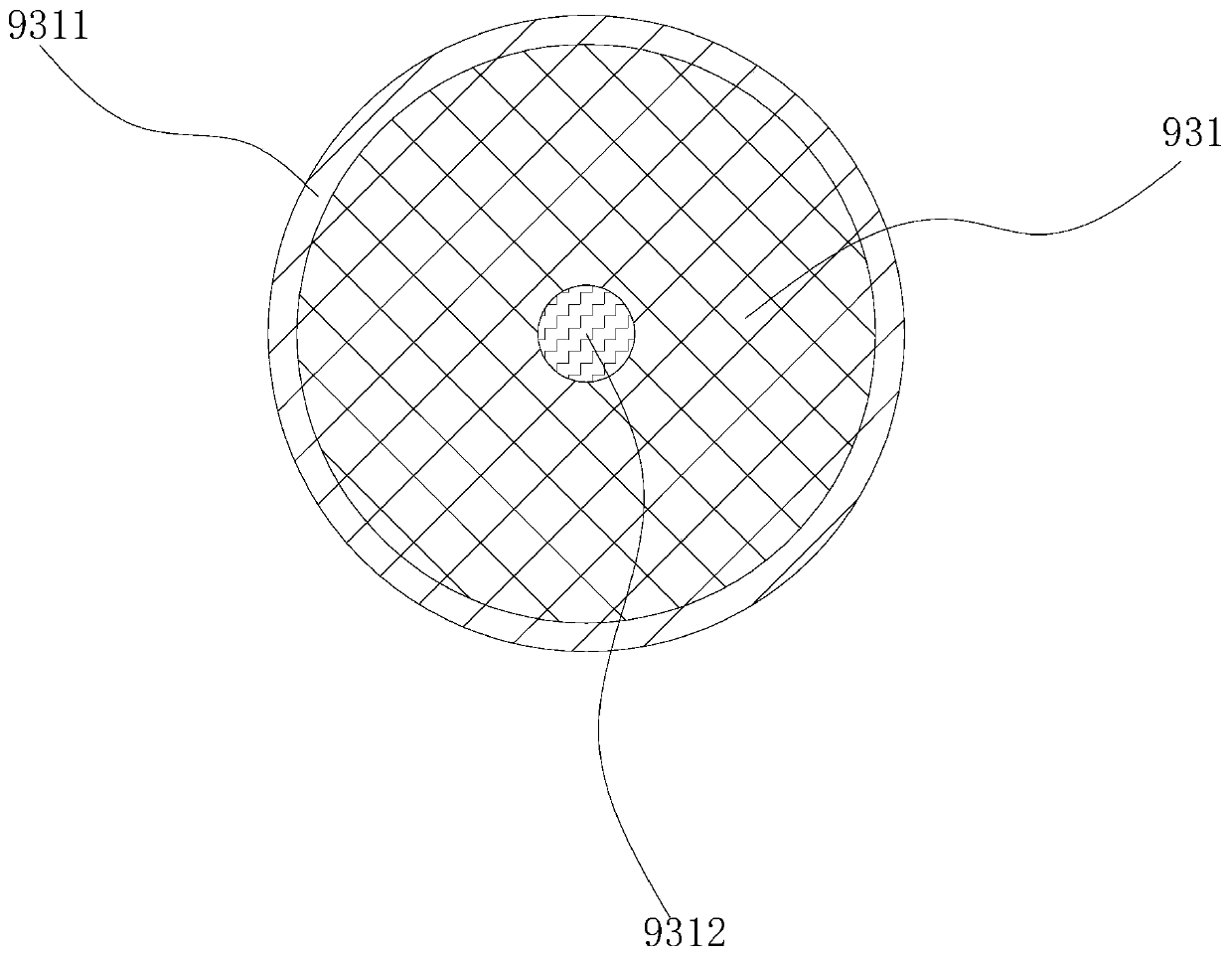

A kind of silk making device that reduces broken wire

ActiveCN108328417BStable tensionModerate tensionFilament handlingAnimal materialConductor CoilMechanical engineering

The invention relates to the technical field of silk preparation, in particular to a silk preparation device capable of reducing broken silks. The silk preparation device capable of reducing broken silks comprises a winding set, a winding motor, a controller and a plurality of silk preparing units, wherein a regulating system is arranged in each silk preparing unit and comprises a detector, a signal processor and an adjusting mechanism; each adjusting mechanism comprises a reducing silk guide roller, an upper silk guide buckle, a lower silk guide buckle, a rotating motor and a swing motor; therotating motors and the swing motors are separately connected to the signal processors; and the controllers are connected to the signal processors. When the silks are too small in tension, the reducing silk guide rollers move toward the back end and the rotating speeds are reduced, so that the silks are prevented from winding reels loosely; when the silks are too large in tension, the reducing silk guide rollers stretch out axially upward forward and the rotating speeds are high, so that the silks are prevented from winding tightly and the tensions of the silks are reduced gradually, and therefore, the tensions of the silks are controlled in the silk preparing process. Meanwhile, the controllers control synchronous operation of the winding motor, the swing motors and the rotating motors.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com