Unloading tobacco material from an intermediate reservoir

A technology of storage and cut tobacco material, which is applied in the direction of tobacco, cigarette manufacturing, application, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

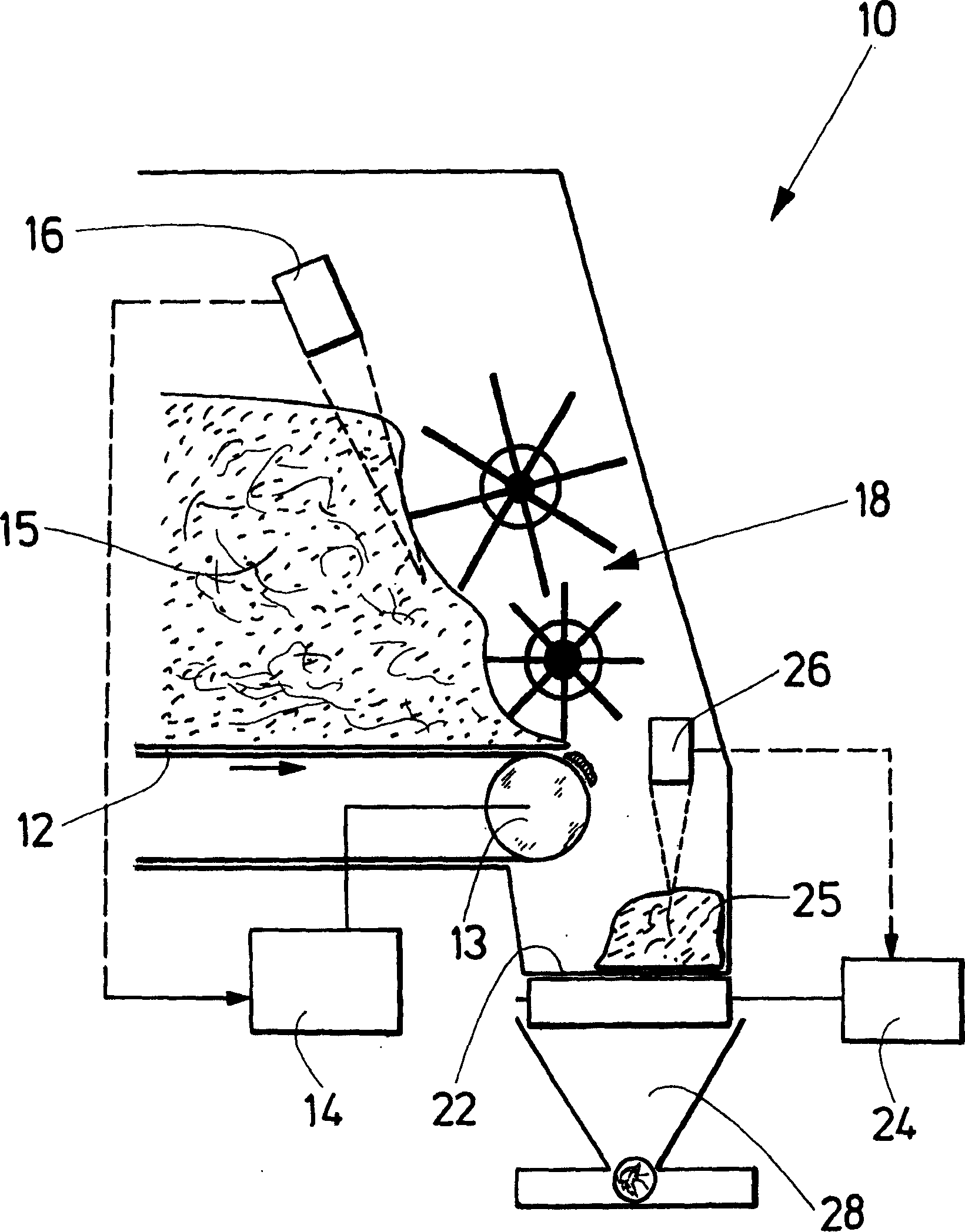

[0022] figure 1 A cross-section of an intermediate store 10 is shown in . Arranged in the intermediate store 10 is a horizontal conveyor belt 12 on which the cut tobacco material 15 is arranged. The conveyor belt 12 transports the cut tobacco material 15 in the direction of a rake mechanism 18 equipped with two hammer rollers. The shredded tobacco is separated from the tobacco charge 15 by means of a rake mechanism 18 as a discharge device and thrown as a portion 25 onto a lower conveyor belt 22 .

[0023] The conveyor belt 12 and the conveyor belt 22 convey the cut tobacco material 15 and the fraction 25 of the separated tobacco material 15 at different levels. The conveying means of the conveyor belts 12, 22 are arranged perpendicular to each other.

[0024] Above the tobacco material 15 , a sensor 16 is arranged in the buffer 10 , with which sensor the quantity of the tobacco material 15 fed to the rake mechanism 18 is detected. The conveying contour of the tobacco mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com