Connecting cloth embossing processing device

A processing device and fabric technology, applied in printing, printing machine, thin material processing and other directions, can solve the problems of inability to adjust, poor adjustment effect, low efficiency, etc., and achieve the effect of not easy to fall off and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

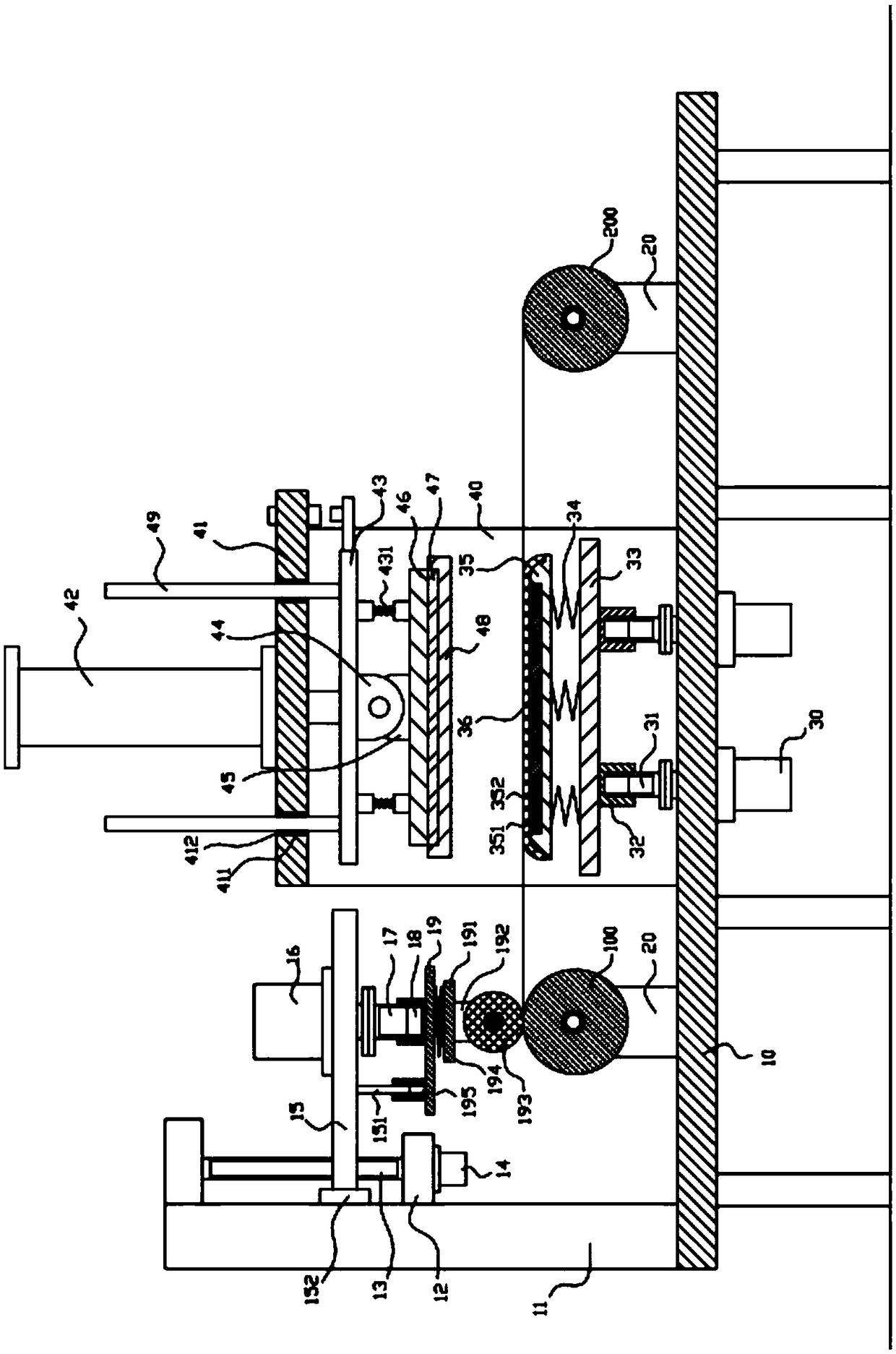

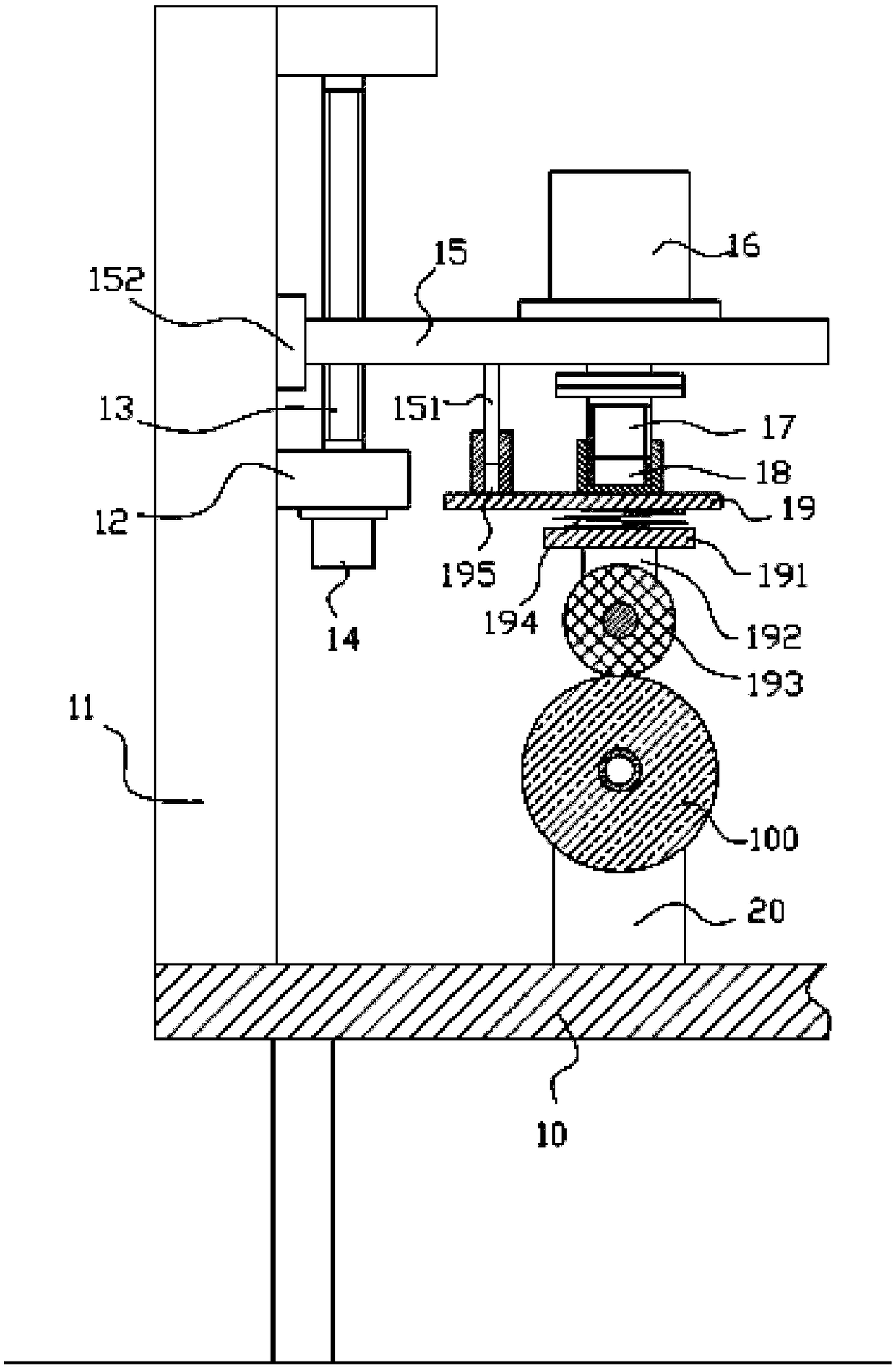

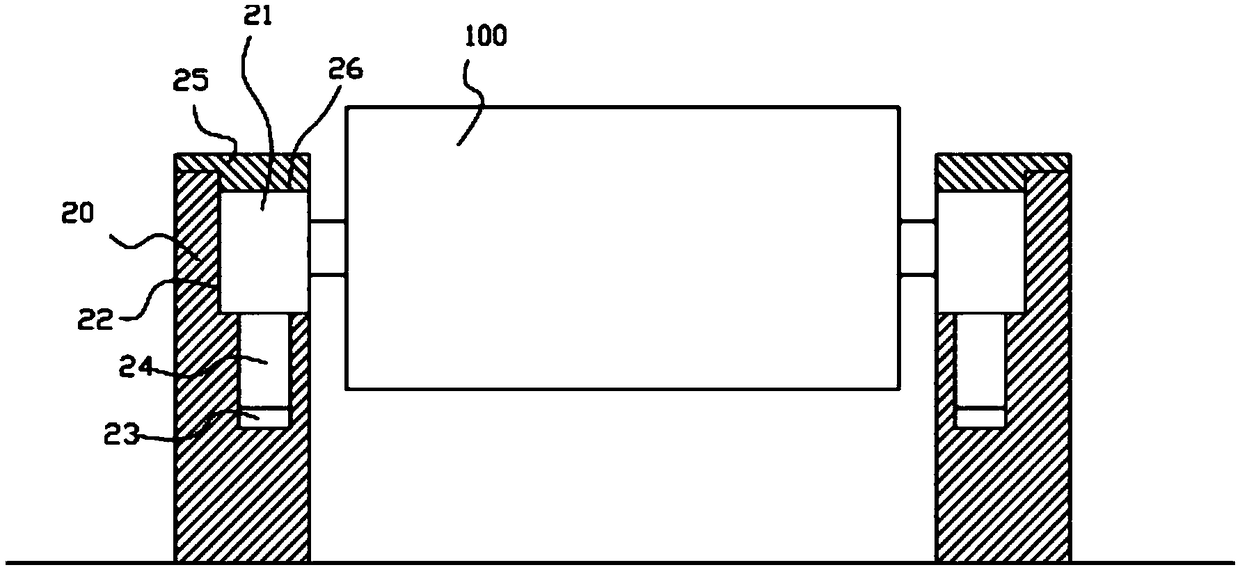

[0028] Example: see Figure 1 to Figure 5 As shown, a device for connecting cloth embossing includes a frame 10, a main vertical support plate 11 is fixed on the left top surface of the top plate of the frame 10, and the rear part of the middle top surface of the top plate of the frame 10 is fixed There is a main vertical plate 40 for processing, the top surface of the main vertical plate 40 is fixed with an upper main horizontal plate 41, the middle top surface of the upper main horizontal plate 41 is fixed with a main compression cylinder 42, and the push rod of the main compression cylinder 42 Pass through the upper main transverse plate 41 and be fixed with the upper lifting connecting plate 43, the bottom surface middle part of the upper lifting connecting plate 43 is fixed with the upper connecting block 44, the upper connecting block 44 is hinged with the lower connecting block 45 by the hinge shaft, the lower connecting block 45 The bottom surface is fixed with an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com