UV machine with damping material collecting and discharging structure

A technology of retracting, unwinding and damping, which is applied in thin material handling, printing, printing devices, etc., can solve the problems of inability to guarantee the tension of the material belt, poor printing effect, waste of material belt, etc., and achieves good printing effect and structure. Simple, good conveying speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

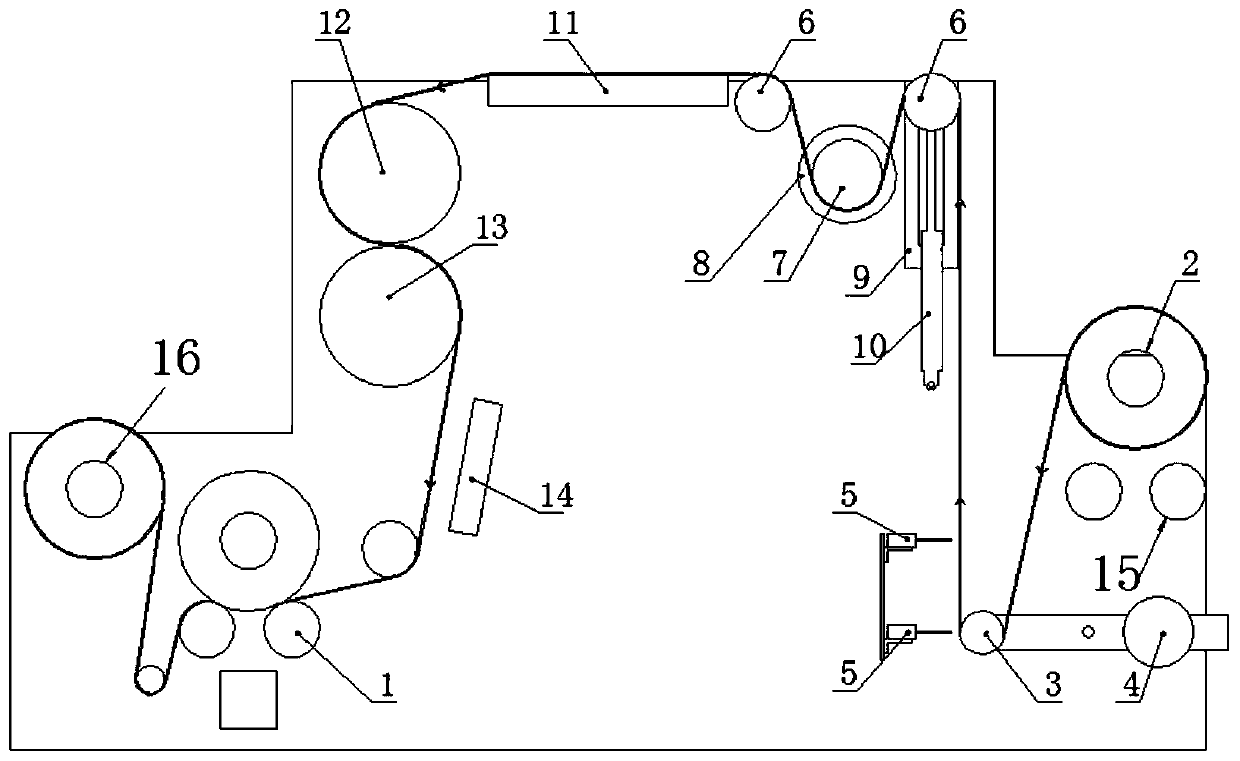

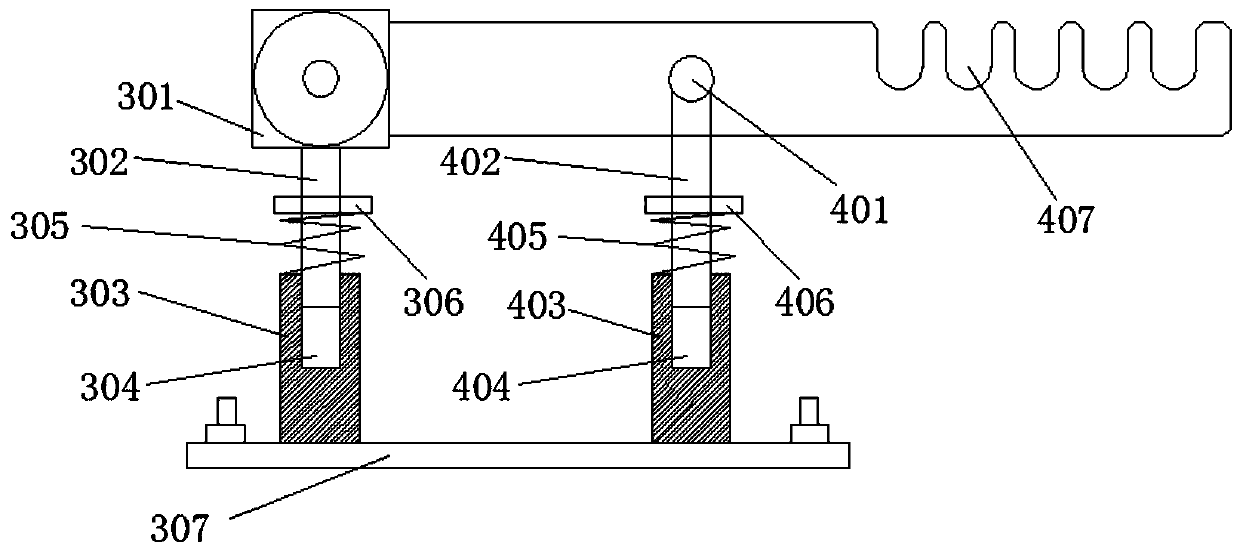

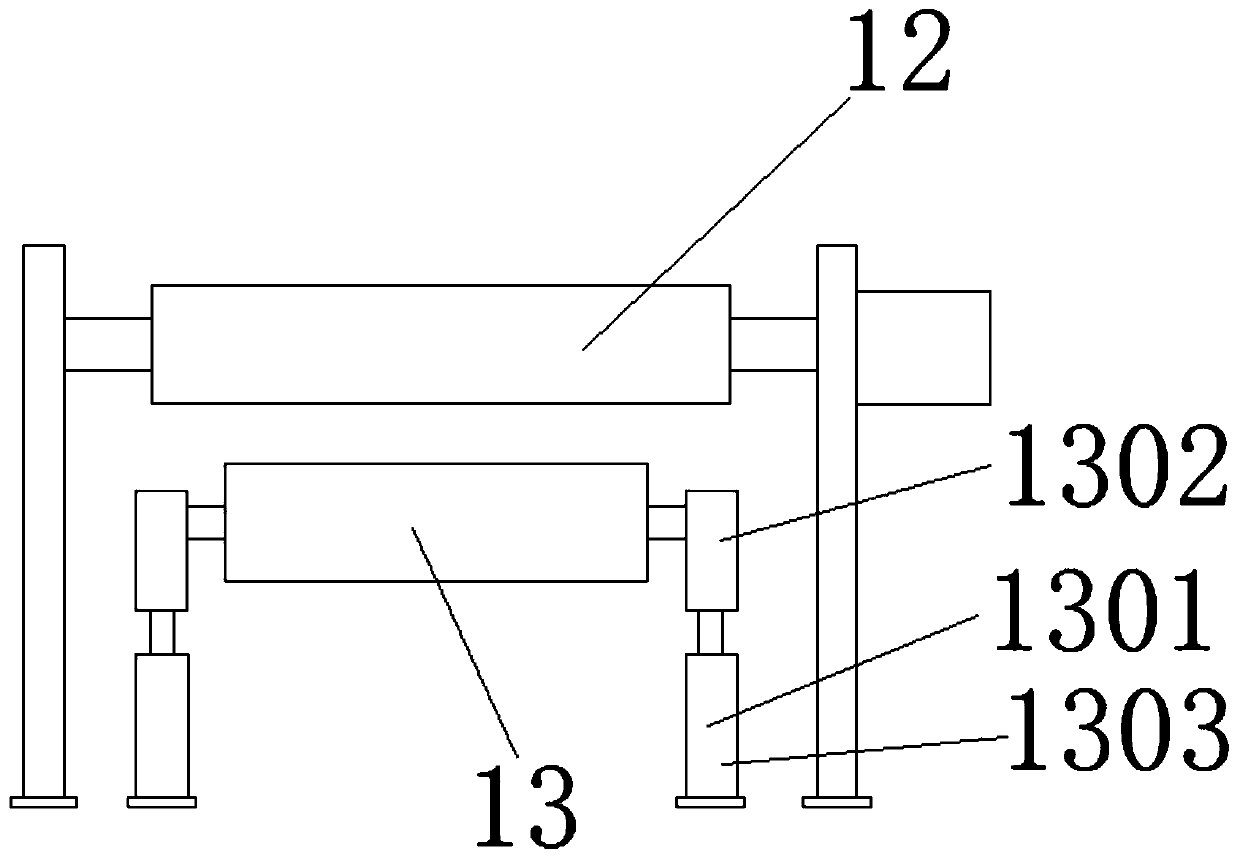

[0018] Such as Figure 1-3 As shown, this embodiment provides a UV machine with a damping structure for retracting and discharging materials, including a discharging air-inflating roller 2, a discharging tensioning roller 3, a steering roller 601, a damping roller 7, and a steering roller 2 602 arranged in sequence. , printing platform 11, main driving roller 12, lower pressure roller 13, light box 14, receiving support roller 1, receiving air-inflating roller 2, and the described discharging air-inflating roller 2 is used to place the material belt, and the The material belt passes through the feeding tension roller 3, turning roller 1 601, damping roller 7, turning roller 2 602, printing platform 11, main driving roller 12, lower pressing roller 13, light box 14, and receiving support roller in sequence 1. Winding on the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com