Multi-gear auxiliary conveying device for packaging paper shell production line

A packaging paper shell and conveying device technology, applied in the field of packaging processing, can solve problems such as affecting processing, affecting processing accuracy, cutting error, etc., and achieving the effect of adjustable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

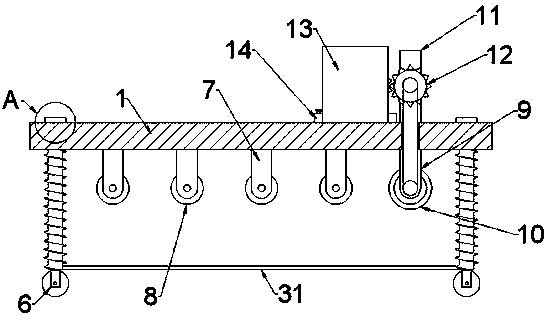

[0019] see Figure 1~2 , in an embodiment of the present invention, a multi-stage auxiliary conveying device for a packaging carton production line includes a beam plate 1, a lifting support structure arranged on both sides of the beam plate 1 for adjustable support, and a support for assisting the movement of the carton. The conveying mechanism and the driving structure 13 used to control the operation of the conveying mechanism, the lifting and supporting mechanisms on both sides are adjusted to lift synchronously through rotation, and the driving structure 13 drives the conveying mechanism to assume different conveying speeds by sliding.

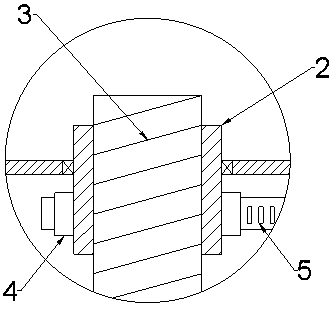

[0020] The beam plate 1 is a metal frame with a hollow structure, and the lower ends of the beam plate 1 are equidistantly connected with a plurality of sets of first support plates 7, and the lower ends of the first support plates 7 are rotatably connected with a pressing wheel 8. A conveying mechanism is also connected to the beam plate...

Embodiment 2

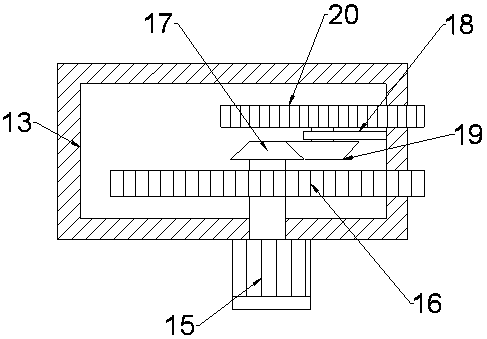

[0025] see image 3 , in an embodiment of the present invention, a multi-stage auxiliary conveying device for a packaging carton production line, the driving structure 13 also includes a motor 15, and the output end of the motor 15 moves through the side wall of the driving structure 13 The outer periphery of the output end of the motor 15 is connected with a first driving gear 16, the end of the output end of the motor 15 is also connected with a first helical gear 17, and the inner side of the driving structure 13 is also provided with a fourth support plate 18, the second helical gear 19 and the second driving gear 20 are arranged on the fourth support plate 18 through the rotational connection of the rotating shaft, the second helical gear 19 and the first helical gear 17 are driven by meshing, and the The second driving gear 20 is smaller than the scale diameter of the first driving gear 16, and the first driving gear 16 or the second driving gear 20 is meshed with the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com