Smelting Production System Based on Continuous Preheating Conveyor

A production system and conveyor technology, applied in the direction of improving process efficiency, manufacturing converters, etc., to achieve the effects of reducing steelmaking sites, reducing energy consumption, and shortening smelting cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

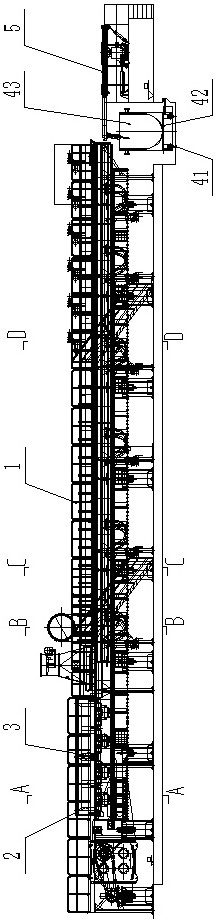

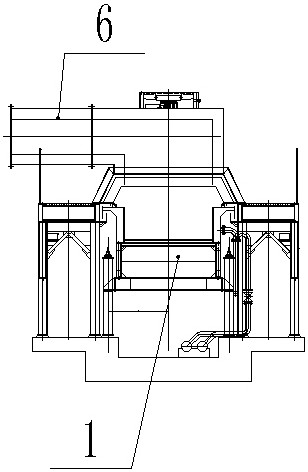

[0062] Such as Figure 1 to Figure 16 As shown, a smelting production system based on a continuous preheating conveyor in this embodiment includes a continuous preheating conveyor 1, and the feeding end of the continuous preheating conveyor 1 is provided with a The cloth vibrating conveyor 2, the cloth vibrating conveyor 2 and the continuous preheating conveyor 1 are vertically arranged on the plane.

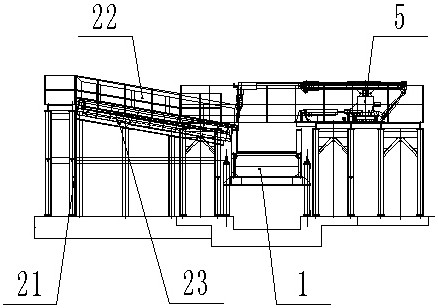

[0063] The cloth vibrating conveyor 2 includes a vibration platform 22 installed on the support base 21, the vibration platform 22 is arranged obliquely downward, and a vibration motor 23 is installed on the lower side of the vibration platform 22, and the vibration platform 22 reciprocates under the action of the vibration motor 23 to realize vibration. Uniform material distribution, avoiding material accumulation caused by dump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com