Composite type oscillation softening machine

A combined and oscillating mechanism technology, applied in the field of softening machines, can solve the problems of difficult to reach a high level of leather, easy slipping of conveyor belts, pollution of the working environment, etc., and achieve the effects of improving the working environment, reliable performance, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

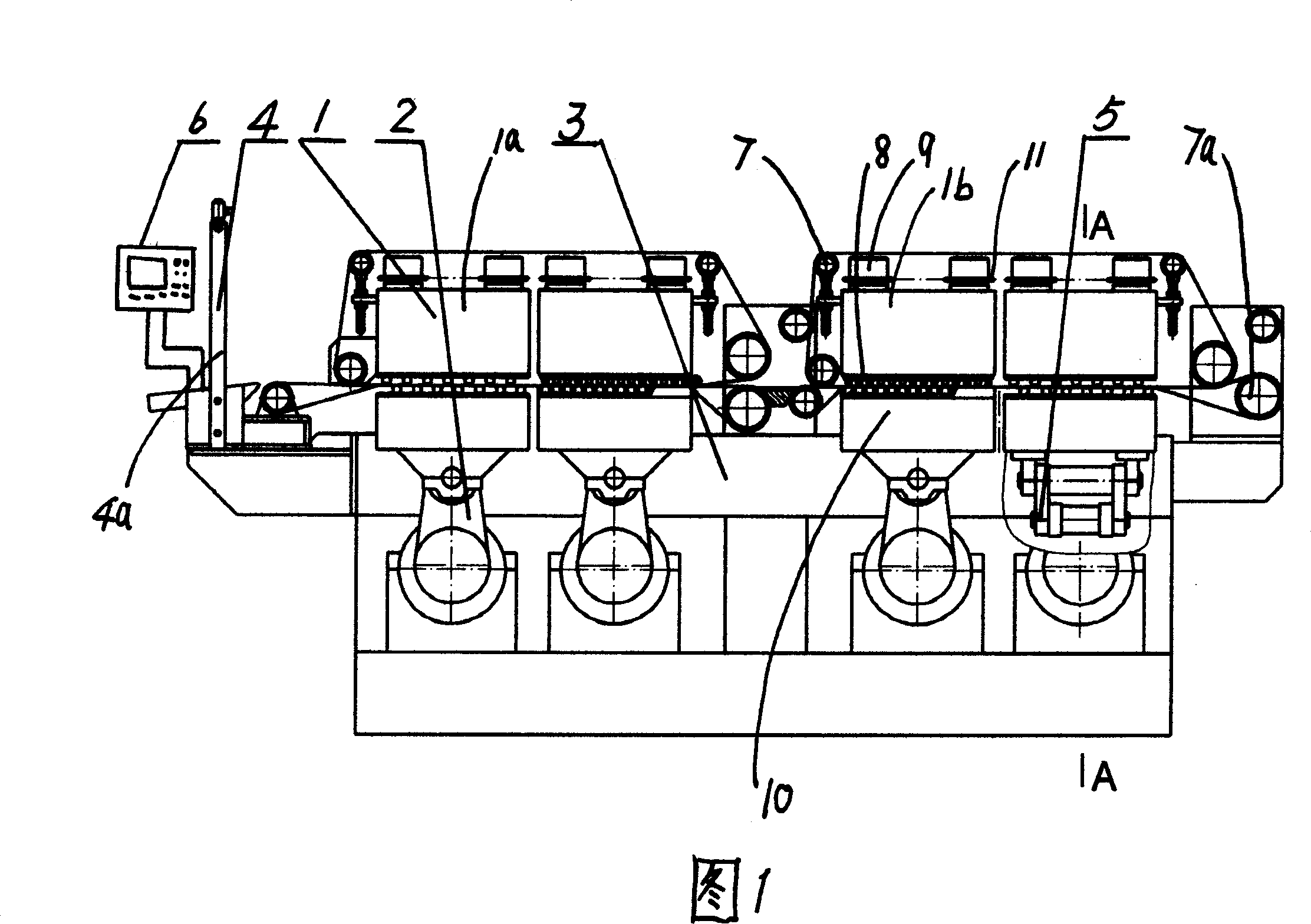

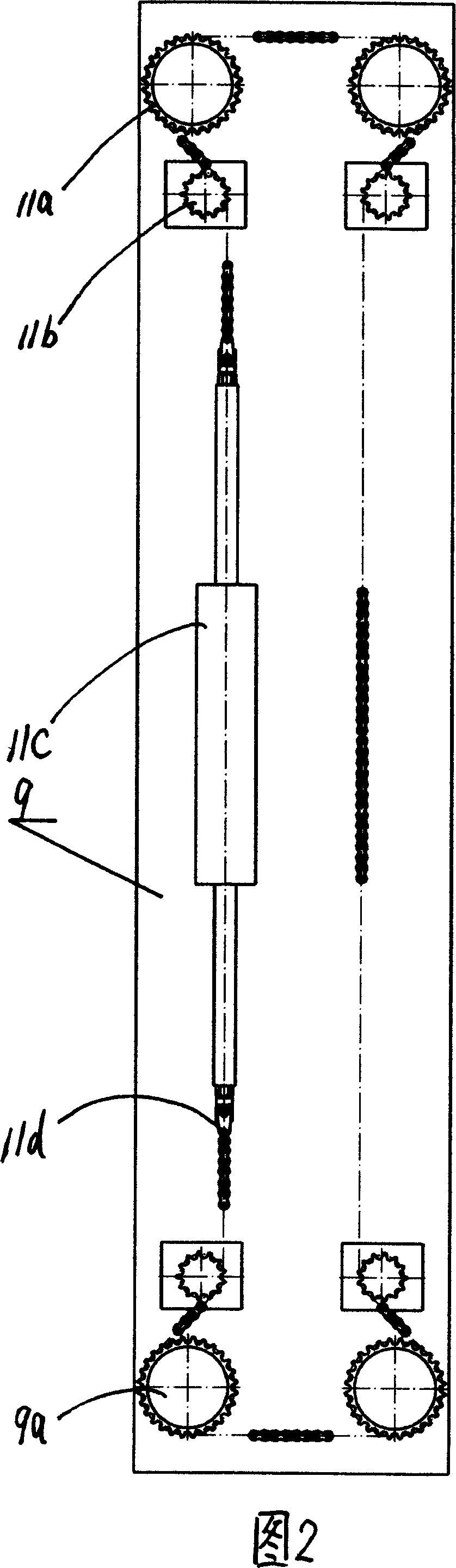

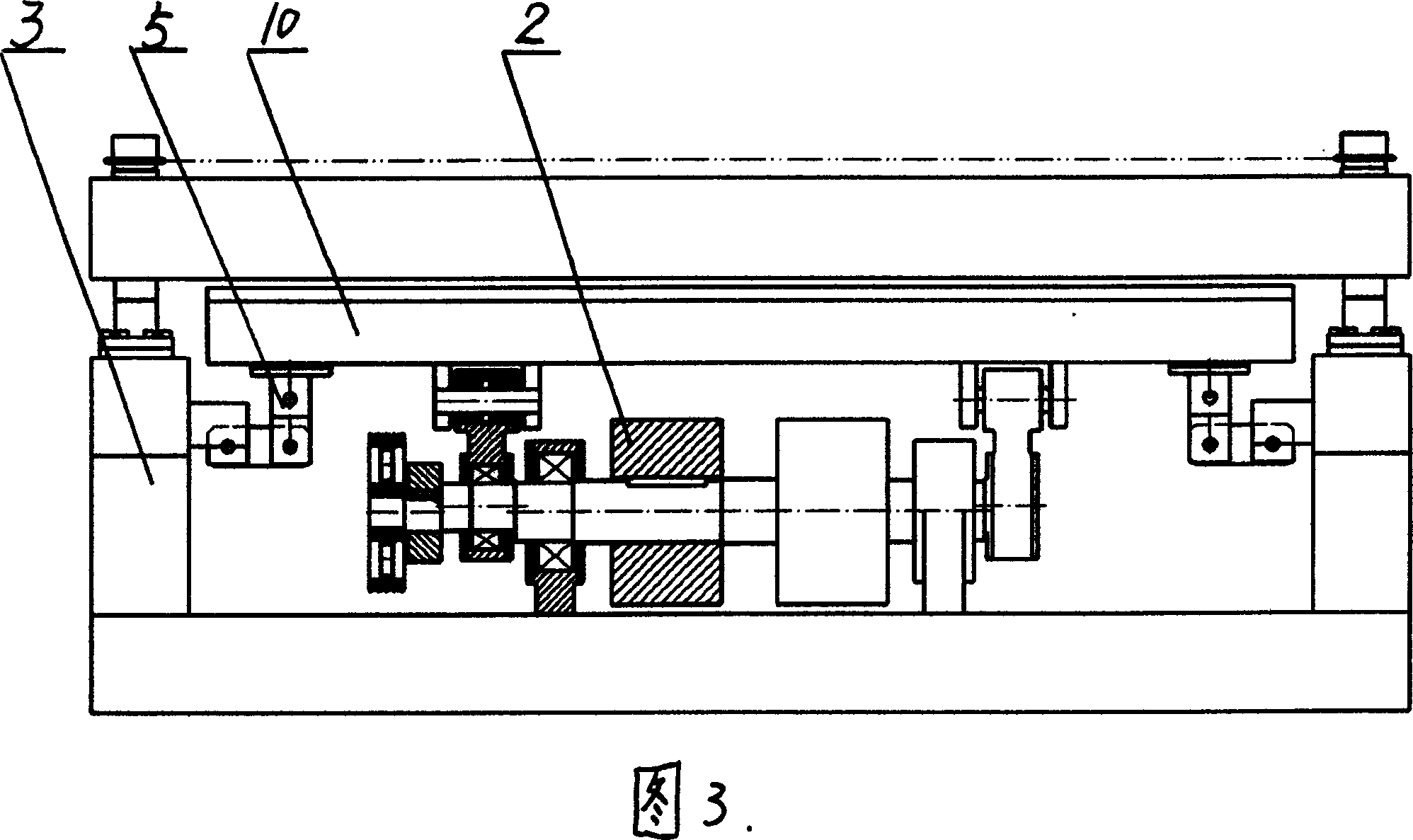

[0014] With reference to accompanying drawing 1, accompanying drawing 3, the present invention comprises at least one set of softening mechanism 1 that can realize automatic adjustment and the oscillating mechanism 2 that is connected with it for driving the softening mechanism 1 to work, the softening mechanism 1 design of the present embodiment For two groups 1a, 1b. The softening mechanisms 1a, 1b and the oscillation mechanism 2 are respectively arranged on the frame 3. Softening mechanism 1 is made up of conveying part 7, upper hole nail plate part 8, fixed seat part 9, lower hole nail plate seat 10, adjustment mechanism 11, upper hole nail plate part 8 links to each other with fixed seat part 9, and in the adjustment mechanism 11 can be adjusted to move up and down; the adjustment mechanism 11 is arranged on the fixed seat part 9; connecting rods. The softening mechanism 1 or the frame 3 is provided with at least one nozzle 4 for spraying water mist. In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com