Plastic dewatering and drying machine

A dryer and plastic technology, applied in dryers, drying gas layout, drying and other directions, can solve the problems of high price, small equipment can not meet production needs, complex structure, etc., to achieve the effect of reducing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

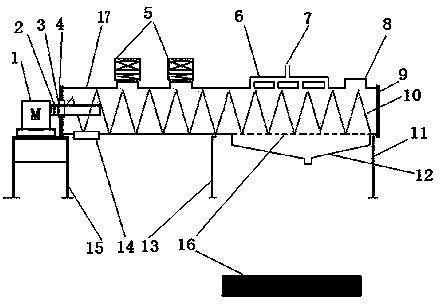

[0021] TB0404-325 stainless steel plastic dehydration dryer.

[0022] TB0404-325 stainless steel plastic dehydration dryer, including outer cylinder, dehydration drying system, conveying mechanism and frame.

[0023] The outer cylinder (17) (length 4000mm and outer diameter 325mm) and the variable frequency speed regulation motor (1) of the conveying mechanism (rotating speed 700, power 4 kilowatts) are installed on the frame and connected together by bolts (M10); the shaft of the conveying mechanism The sleeve (3) (shaft diameter 40mm) is installed on the top cover (4) of the outer cylinder and connected together by bolts (M10); the hot air blower (5) (electric heating power 9 kW) of the dehydration drying system is installed on the outer cylinder (17) on the reserved connecting frame on the upper part; four air ducts (6) (50mm in diameter) are welded on the reserved holes on the upper part of the outer cylinder (17).

[0024] Frame is made up of motor support (15), middle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com