PBT (polybutylene terephthalate) composite filtering material for fuel filter and preparation method

A fuel filter and filter material technology, applied in chemical instruments and methods, separation methods, filter paper, etc., can solve the problems of large gaps in the filter material, affecting the service life, reducing the dirt holding capacity, etc., to improve the filtration efficiency and accuracy. , Excellent flexibility and temperature resistance, the effect of avoiding bending damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

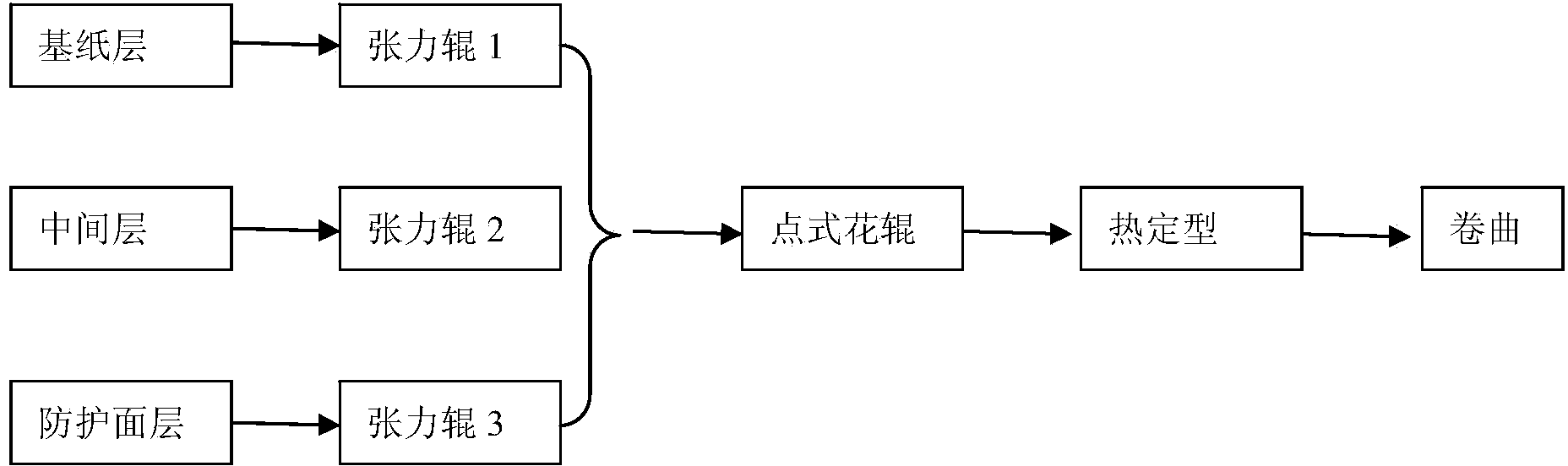

Method used

Image

Examples

Embodiment 1

[0058] 1. Preparation of base paper layer:

[0059] The specific steps of preparing the base paper layer are mixing, wet slurry, paper forming, drying and coiling. Wherein, the base paper layer contains three kinds of ultrafine chopped fibers with a length of 2 mm, namely: PBT fiber, viscose fiber and PVA fiber; wherein, PBT fiber accounts for 5% of the total weight, and its fineness is 0.5 dtex; viscose fiber accounts for 50% of the total weight, and its fineness is 0.3dtex; PVA fiber accounts for 40% of the total weight, and its fineness is 0.8dtex.

[0060] 2. Preparation of the middle layer:

[0061] The specific steps of preparing the intermediate layer include PBT slicing, drying, screw melting, metering pump, hot air, fine flow stretching to form a web, cooling and forming, and coiling. Wherein, the middle layer is PBT melt-blown fine cloth, and its grammage is 20g / m 2 , with a fiber diameter of 0.1 μm. The specific process parameters are: slice drying: pre-crystall...

Embodiment 2

[0067] 1. Preparation of base paper layer:

[0068] The specific steps of preparing the base paper layer are mixing, wet slurry, paper forming, drying and coiling. Wherein, the base paper layer contains three kinds of ultrafine chopped fibers with a length of 6 mm, namely: PBT fiber, viscose fiber and PVA fiber; wherein, PBT fiber accounts for 15% of the total weight, and its denier is 0.8 dtex; viscose fiber accounts for 40% of the total weight, and its fineness is 0.8dtex; PVA fiber accounts for 50% of the total weight, and its fineness is 2.2dtex.

[0069] 2. Preparation of the middle layer:

[0070] The specific steps of preparing the intermediate layer include PBT slicing, drying, screw melting, metering pump, hot air, fine flow stretching to form a web, cooling and forming, and coiling. Wherein, the middle layer is PBT melt-blown fine cloth, and its grammage is 50g / m 2 , with a fiber diameter of 15 μm. The specific process parameters are: slice drying: pre-crystalliz...

Embodiment 3

[0076] 1. Preparation of base paper layer:

[0077] The specific steps of preparing the base paper layer are mixing, wet slurry, paper forming, drying and coiling. Wherein, the base paper layer contains three kinds of ultrafine chopped fibers with a length of 4 mm, namely: PBT fiber, viscose fiber and PVA fiber; wherein, PBT fiber accounts for 5% of the total weight, and its denier is 0.7 dtex; viscose fiber accounts for 45% of the total weight, and its fineness is 0.6dtex; PVA fiber accounts for 50% of the total weight, and its fineness is 1.8dtex.

[0078] 2. Preparation of the middle layer:

[0079] The specific steps of preparing the intermediate layer include PBT slicing, drying, screw melting, metering pump, hot air, fine flow stretching to form a web, cooling and forming, and coiling. Wherein, the middle layer is PBT melt-blown fine cloth, and its grammage is 40g / m 2 , with a fiber diameter of 10 μm. The specific process parameters are: slice drying: pre-crystalliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com