Welding type slab crack joint for precast concrete floor system

A technology of prefabricated concrete and connecting nodes, which is applied to roofs, building components, buildings, etc., can solve the problems of unfavorable structural cost, low degree of industrialization, and large earthquake action, so as to improve normal service performance, reduce vibration effect, and increase bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

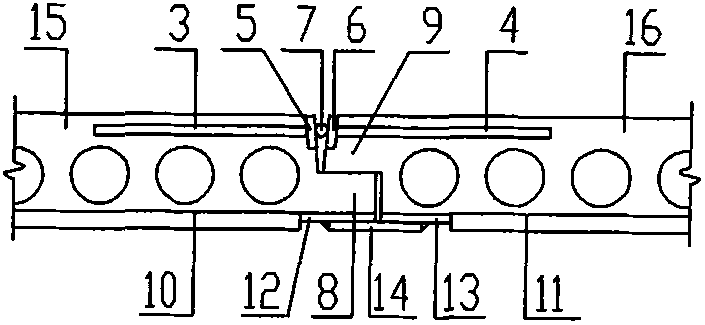

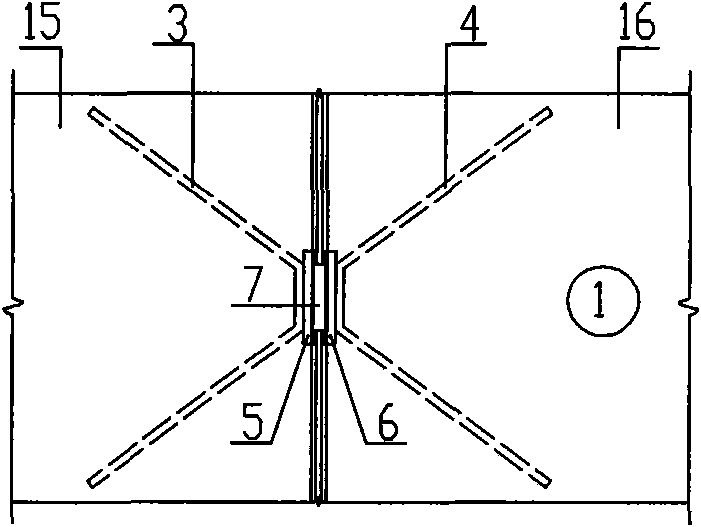

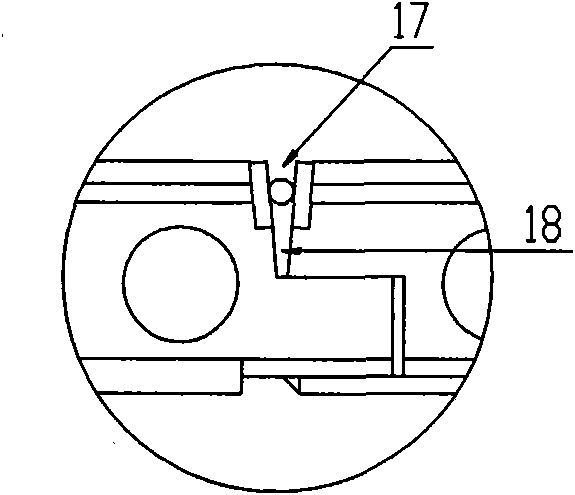

[0021] Below with reference to accompanying drawing, embodiment of the present invention is described in detail:

[0022] The prefabricated concrete floor welded slab seam connection node of the present invention includes a support plate 15 with a built-in first slab bottom steel bar 10 and a supported plate 16 with a built-in second slab bottom steel bar 11, and an external platform 8 is arranged on the support plate 15 , an overhanging platform 9 is provided on the supported plate 16, the overhanging platform 8 and the overhanging platform 9 overlap each other, and an X-shaped connector 1 is provided on the supporting plate 15 and the top area of the supported plate 16, The X-shaped connector 1 includes a first embedded part embedded in the support plate 15 and a second embedded part embedded in the supported plate 16, and the first embedded part is formed by the first anchor bar 3 and the first panel 5, and the first anchor bar 3 is connected to the first panel 5, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com