Grinding disc devices for hand-operated grinding instruments

A grinding disc, hand-operated technology, applied in grinding/polishing safety devices, grinding/polishing equipment, grinding machines, etc., can solve problems such as material damage, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

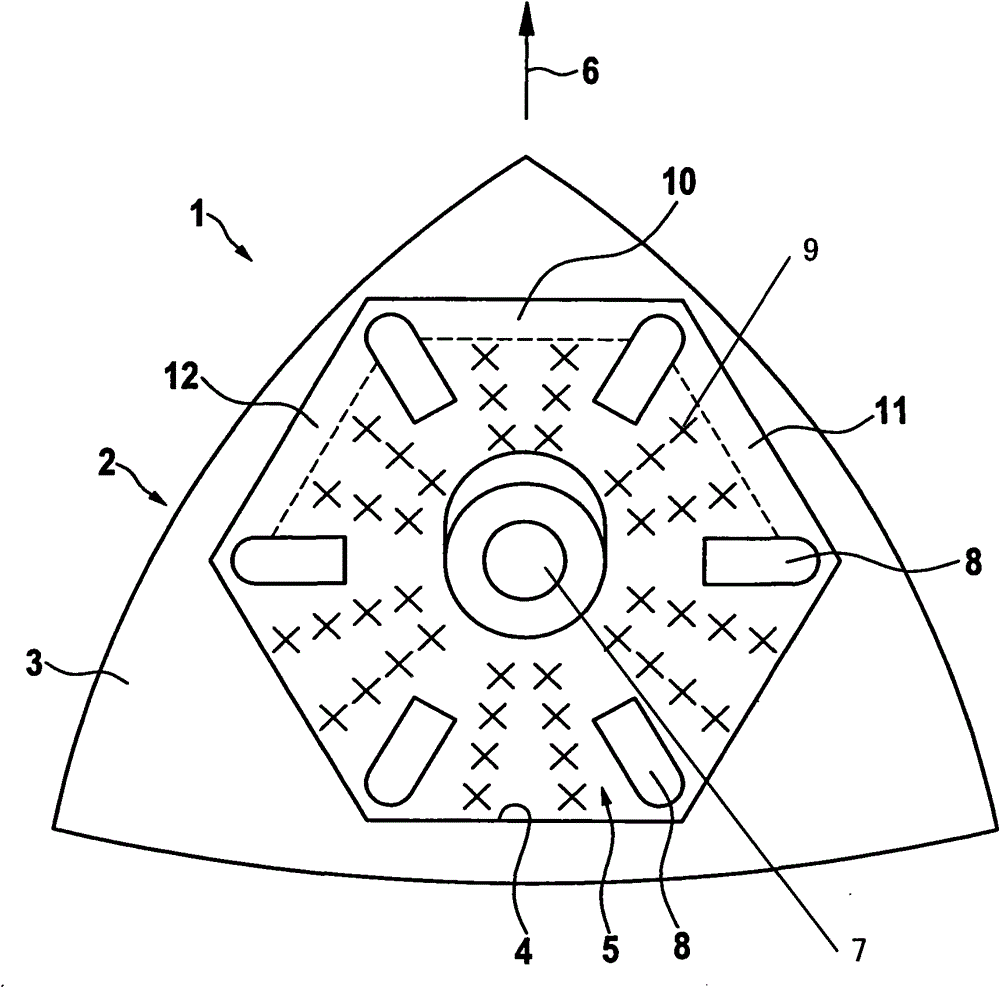

[0018] The figure shows a grinding disc arrangement 1 for a hand-operated grinding tool, in particular for an eccentric grinding machine. The grinding disc arrangement 1 comprises a motor-driven grinding disc 2 and a grinding disc 5 which is positively received in a recess 4 on the bottom surface 3 of the grinding disc 2 . The recess 4 on the base 3 has delimiting walls which delimit the removably inserted grinding disc 5 on all sides. The recess 4 is preferably embodied in such a way that the processing side of the inserted grinding disc 5 and the surrounding area of the bottom surface 3 of the grinding disc 2 lie in a common plane. The recess 4 and the grinding disc 5 have a hexagonal contour in the exemplary embodiment. In contrast, the grinding disk 2 has an at least approximately triangular contour, wherein the outer triangular sides are curved concavely, that is to say radially outward. The machining direction is indicated by an arrow 6 ; the outer contour of the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com