An online method for opening holes in a coke oven brick-concrete chimney

A technology of coke oven bricks and chimneys, which is applied to the heating of coke ovens, coke ovens, coke oven parts, etc. It can solve problems such as the difficulty of opening holes, shorten the opening time, reduce construction intensity, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

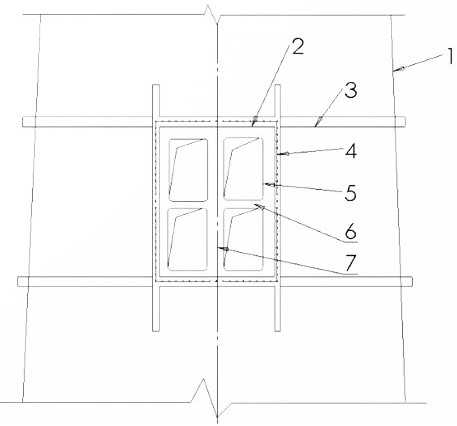

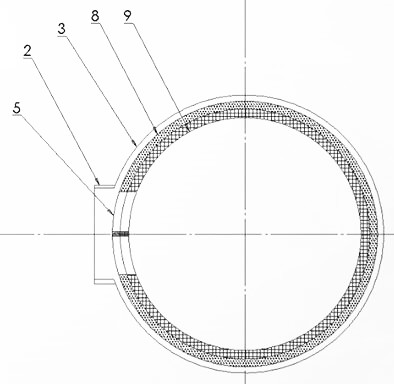

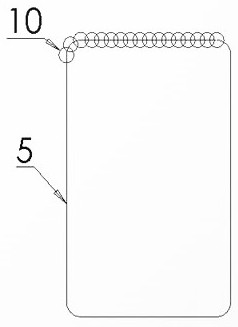

[0030] Embodiment 1: An online opening method for a brick-concrete structure chimney of a coke oven. The control method includes the following steps: 1) The opening structure is designed, and the large-diameter air inlet is divided into several grids. Small holes can ensure the structural strength of the chimney concrete and clay brick layer, and can also ensure sufficient air-introduction channels; 2) Integral pouring of the air-introduction door. Reinforced concrete structure is used to cast the air induction door as a whole, and the connecting parts are pre-embedded to prepare for the subsequent connection of external process pipelines, which can ensure the tightness of the connecting pipelines, facilitate construction operations, and also reinforce the opening parts; 3) adopt The layered drilling method can prevent the two-layer structure inside and outside the chimney from being greatly damaged, and at the same time prevent a large amount of cold air from being sucked into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com