Spring compression conveying device

A conveying device and conveyor belt technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of increasing friction between conveyor belts/conveyor chains and baffles, easily damaged conveyor belts/conveyor chains, pulleys/ Problems such as the inability of the sprocket to rotate, to achieve the effect of improving the tension effect, simplifying the structure, and reducing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Aiming at the deficiencies of the prior art, the present invention aims to provide a spring compression conveying device.

[0026] To achieve the above object, the present invention adopts the following technical solutions:

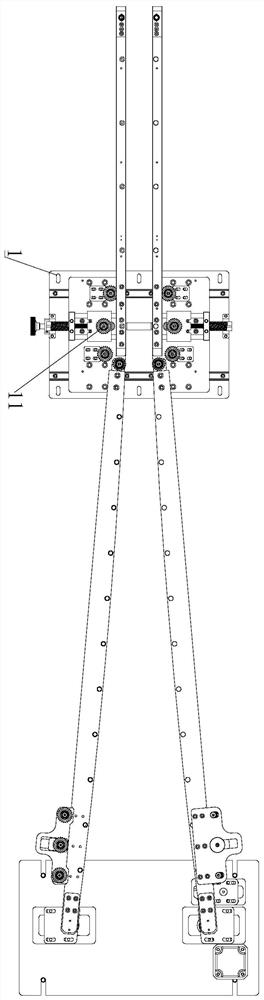

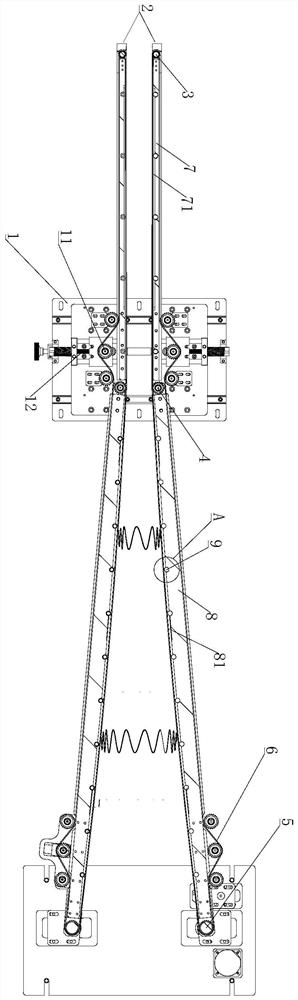

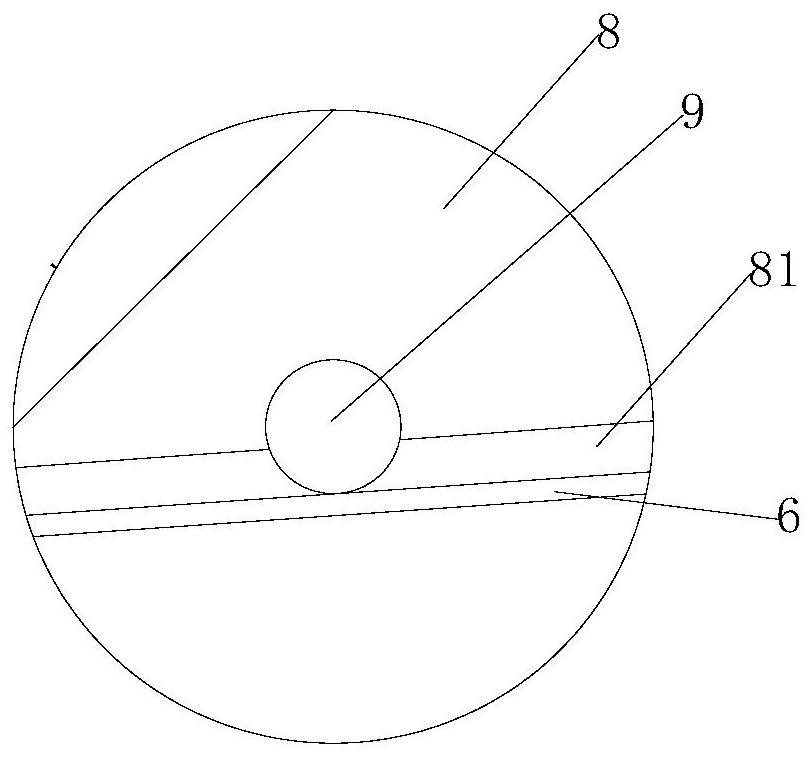

[0027] A spring compression conveying device, comprising a chassis 1 and a conveying mechanism 2, the two conveying mechanisms 2 are arranged oppositely, and the conveying mechanism 2 is formed by winding a section of conveying belt / conveying chain 6, and the conveying belt / conveying chain 6 constitute a flat delivery section 21 and an arc section 22, the arc section 22 is in a convex arc shape, the output end of the arc section 22 is tangent to the input end of the flat delivery section 21, and the flat delivery section Section 21 and circular arc section 22 are not provided with baffle plate, and some columns 9 are all arranged in described flat delivery section 21 and circular arc section 22. The chains 6 are all wound on the uprights 9 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com