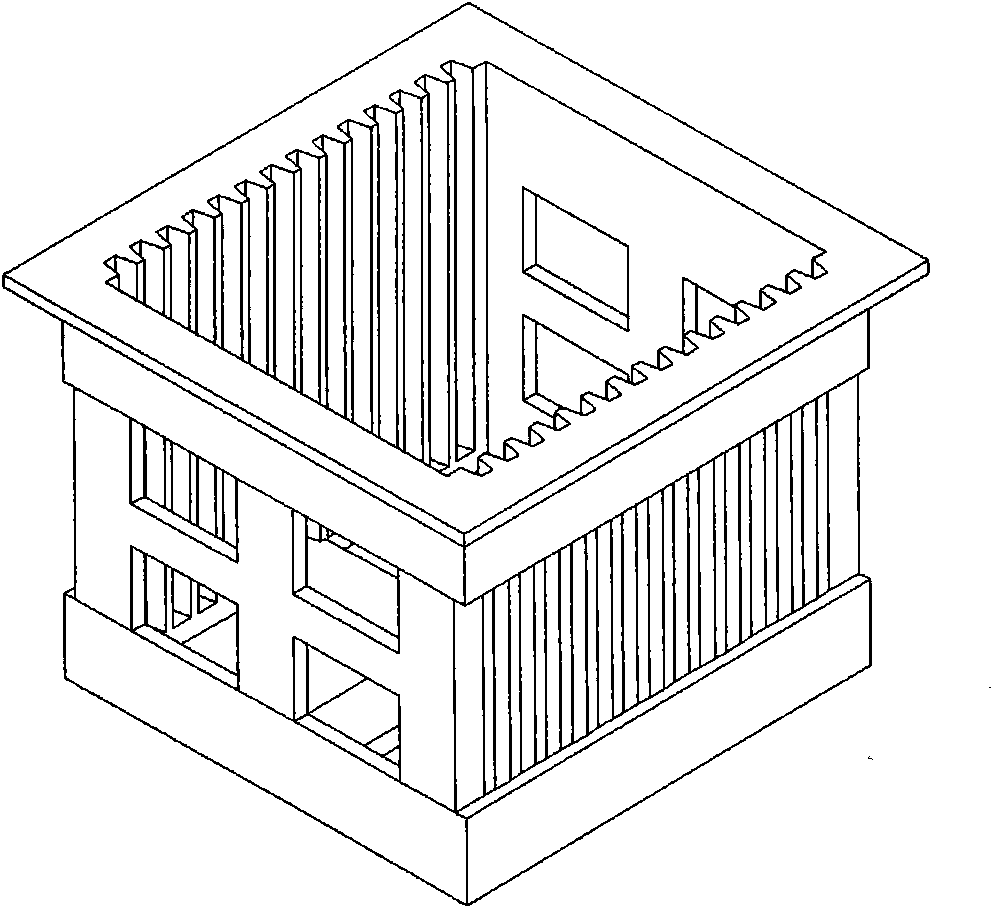

Adjustable bearing cleaning apparatus for processing hard surface photomask base plate and assembling method thereof

A photomask and adjustable technology, which is applied in the field of optical glass processing and hard-surface photomask substrate manufacturing, can solve the problems of brittle material workpiece damage, affecting cleaning effect, blocking water flow, etc., so that it is not easy to damage the workpiece and has good versatility , Increase the effect of water contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

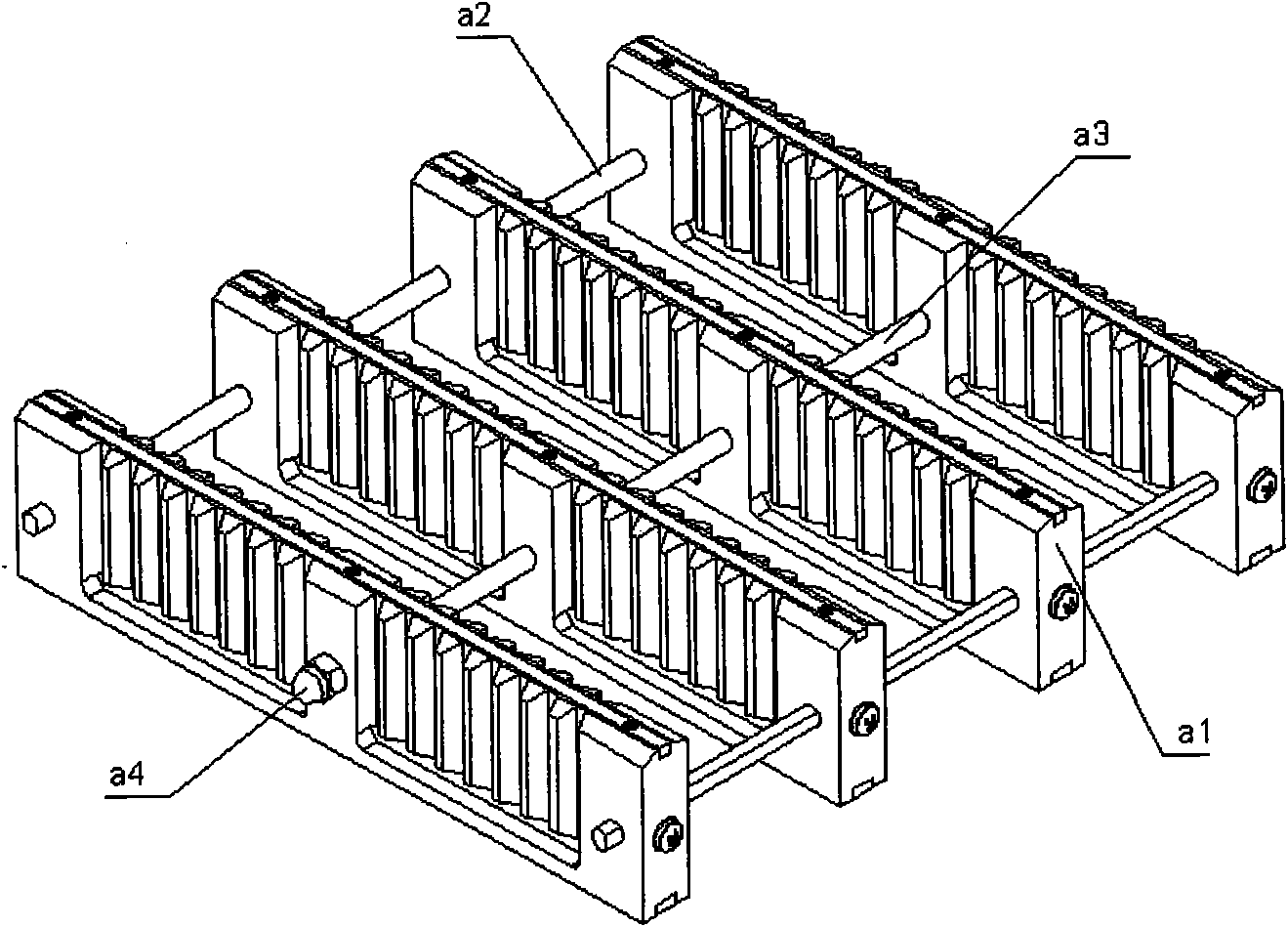

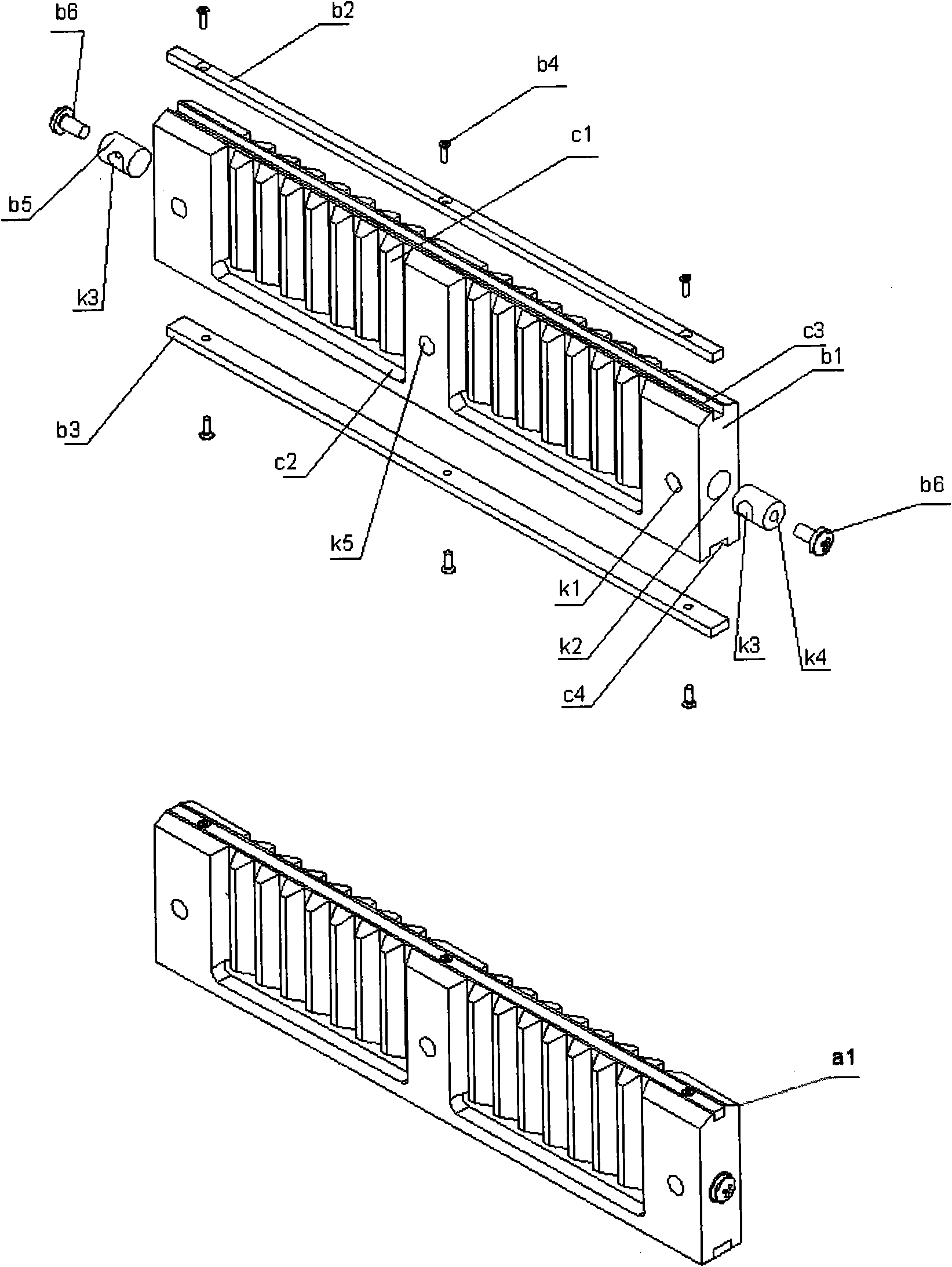

[0024] The structure and assembly method of the cleaning appliance of the present invention will be described below by taking the cleaning of 2.5-inch and 3.5-inch hard-surface photomask substrates as an example. Please refer to Figures 5 and 6 together. The specification of the 2.5-inch hard-surface photomask substrate is 63.5 mm×63.5mm×3.05mm, the size of the 3.5-inch hard-surface photomask substrate is 88.9mm×88.9mm×3.8mm.

[0025] Step 1. Fix the 1# notch frame a1 to the ends of the two guiding and positioning rods a2 passing through the two end guiding and positioning holes k1 with the positioning screw b6, and the guiding rod a3 passes through the middle positioning hole k5. refer to Figure 5-1 .

[0026] Step 2, 2# notch frame a1 and 1# notch frame a1 are parallel and juxtaposed in the same direction, and the two guide positioning rods a2 and guide rod a3 pass through the corresponding end guide positioning hole k1 of 2# notch frame a1 and the middle positioning hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com