Hinge for a window or a door

A hinge and bearing pin technology, applied in the field of hinges, can solve the problems of complex introduction of hinge pins and narrow site conditions, and achieve the effects of simplified operation, simplified manufacturing, and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

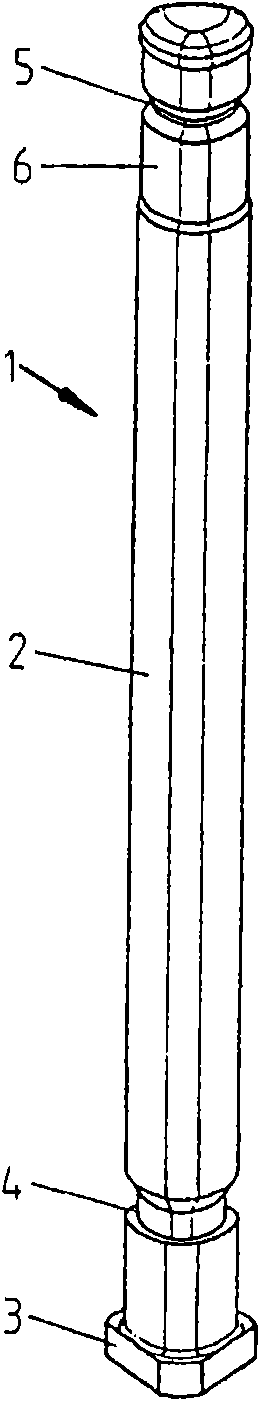

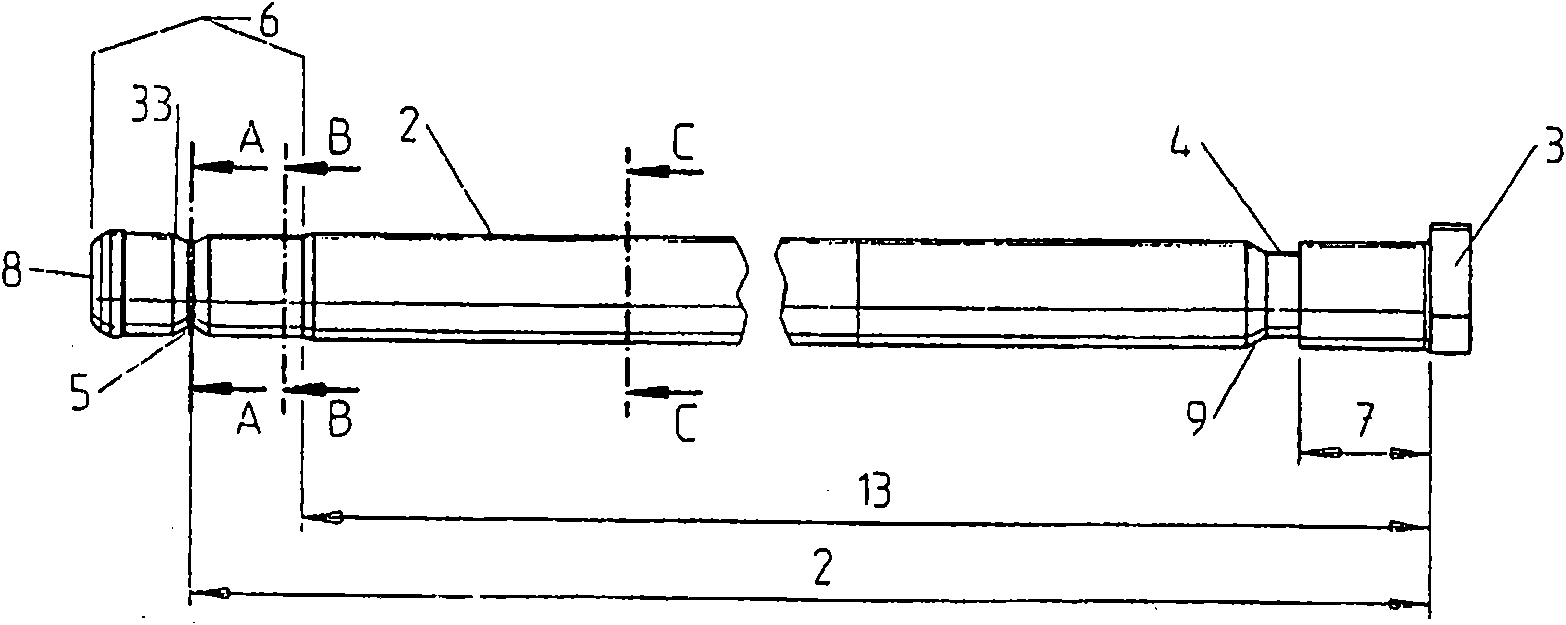

[0026] according to figure 1 As shown, a bearing pin 1 for a hinge for a window or door is designed as a long pin with a head 3 thickened relative to a shaft 2 . The shank 2 has grooves 4 , 5 and a taper 6 at the end, the groove 5 being in the region of the taper 6 .

[0027] to combine figure 2 It can be seen that the groove 4 is widened relative to the groove 5 and has, in the groove wall at a distance 7 from the head 3 , a run at right angles to the shaft 2 , while the groove wall 9 inclined in the direction of the end 8 has a A gentler angle. The groove 5 is formed almost as a groove by two groove walls 10 , 11 running at gentle angles. The distance 12 from the groove 5 to the head 3 is indicated, while the taper 6 starts at a distance 13 .

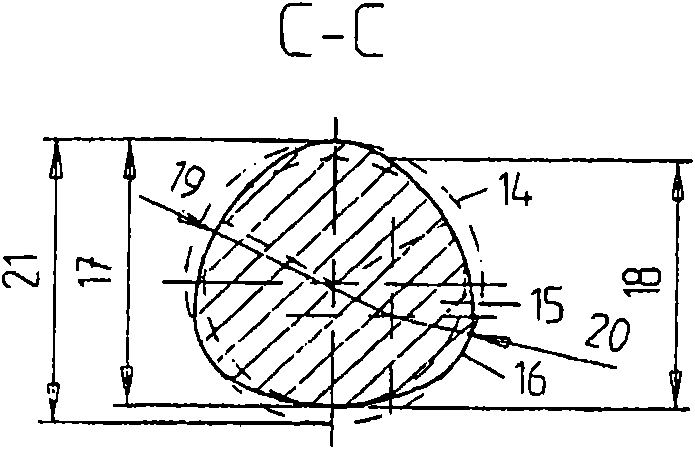

[0028] with the help of image 3 , 4 combined with 5 figure 2 It can be seen that the bearing pin has a kind of image 3 Different cross-sectional shapes 15 of the circle 14 indicated by dashed lines.

[0029] The shank 2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com