Electrostatically driven mems comb-tooth structure, micromirror using the structure and preparation method thereof

An electrostatic drive and comb-tooth structure technology, applied in the field of micromirrors and their preparation, and electrostatic drive MEMS comb-tooth structure, can solve problems such as explosion and comb-tooth damage, and achieve the effects of simple process, structure prevention and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below with reference to the accompanying drawings.

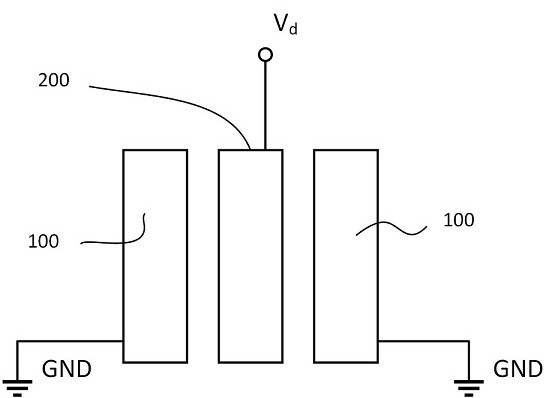

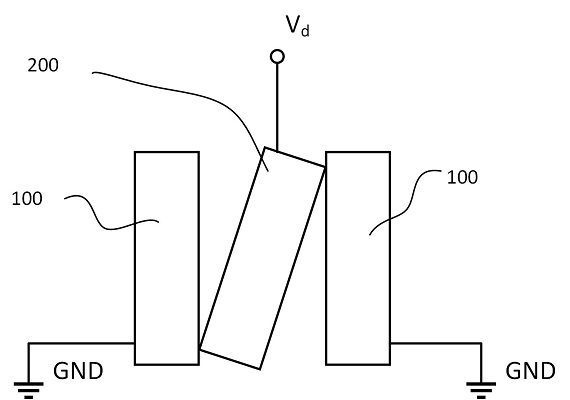

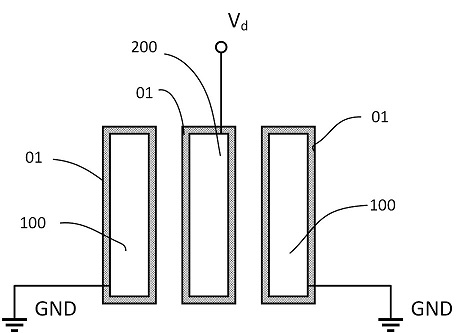

[0050] The electrostatically driven MEMS comb-tooth structure has an insulating layer 01 on the surface of the comb-tooth, and the insulating layers on the surfaces of adjacent comb-tooths are the same insulating layer or different insulating layers. In the normal state, there is a gap between the comb teeth, as shown in Figure 2(a).

[0051] The electrostatically driven MEMS comb structure includes at least one group of driving combs 200 and at least one group of grounding combs 100, wherein the driving combs are connected to a driving voltage, and the grounding combs are grounded; each group of driving combs and grounding combs The number of comb teeth is greater than or equal to 1; the driving comb tooth group and the grounding comb tooth group are staggered and interdigitated, that is, the two sides of each driving comb tooth are grounding comb teeth or have no str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com