Automobile spare part machining mold

A technology for processing molds and spare parts, which is applied in the field of processing molds for auto parts. It can solve the problems of inconvenient cleaning of debris in stamping molds, and achieve the effects of convenient manual processing and assembly, low production costs, and improved manufacturing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

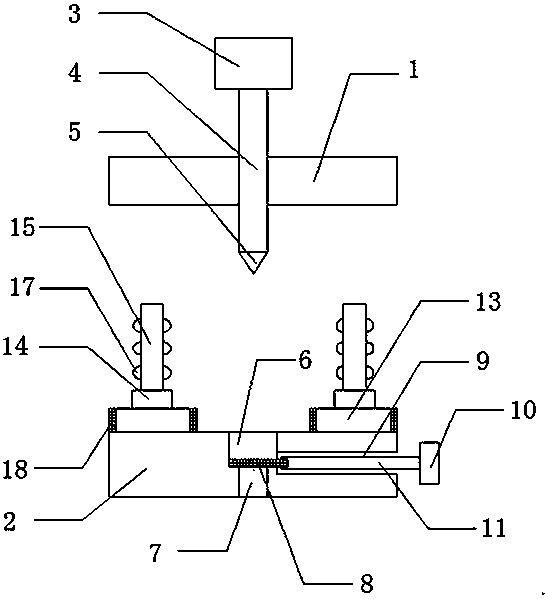

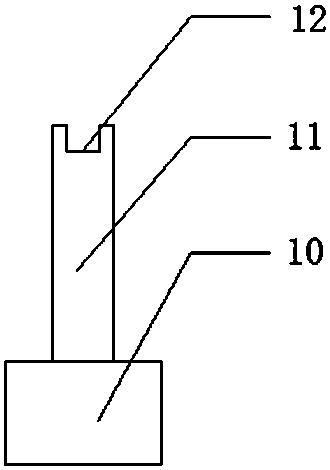

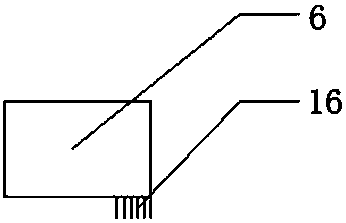

[0020] Refer to attached Figure 1-3 As shown, a mold for processing auto parts includes a lower mold 2 and an upper mold 1 opposite to the lower mold 2. A stamping cylinder 3 is arranged above the upper mold 1, and an output shaft 4 at the end of the stamping cylinder 3 runs through the upper mold 1. Set in the center, a stamping head 5 is provided under the output shaft 4, a stamping groove 6 is provided at the center of the lower die 2, the stamping groove 6 is located directly below the stamping head 5, and a discharge hole is provided below the stamping groove 6 7. A baffle 8 is provided between the stamping groove 6 and the discharge hole 7, a rectangular channel 9 is arranged axially on the right side of the lower die 2, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com