Methanol burner

A burner, methanol technology, applied in burners, lighting and heating equipment, etc., can solve the problems of insufficient combustion, flame shape and length shaping, and insufficient combustion of methanol burners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

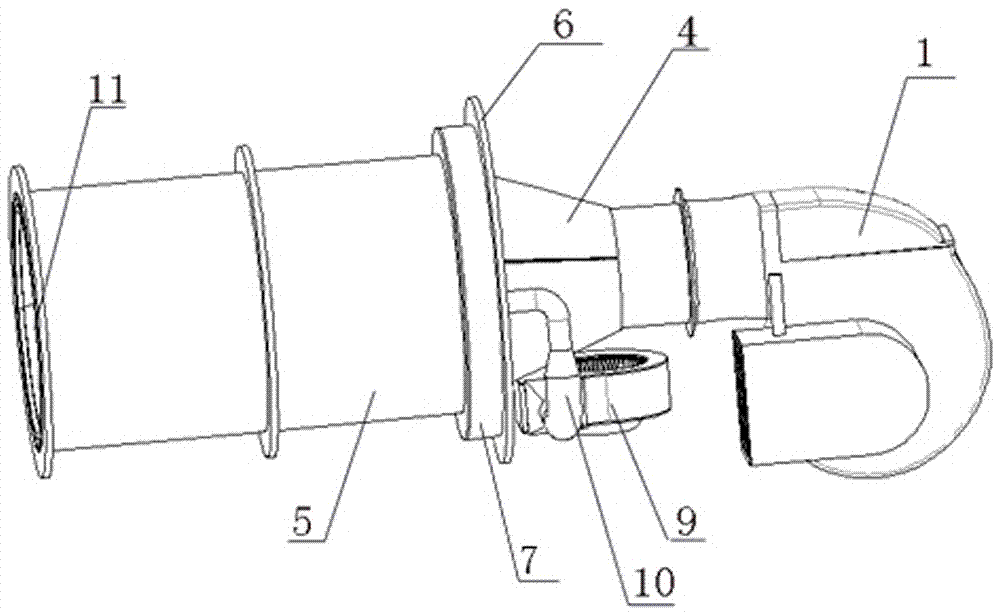

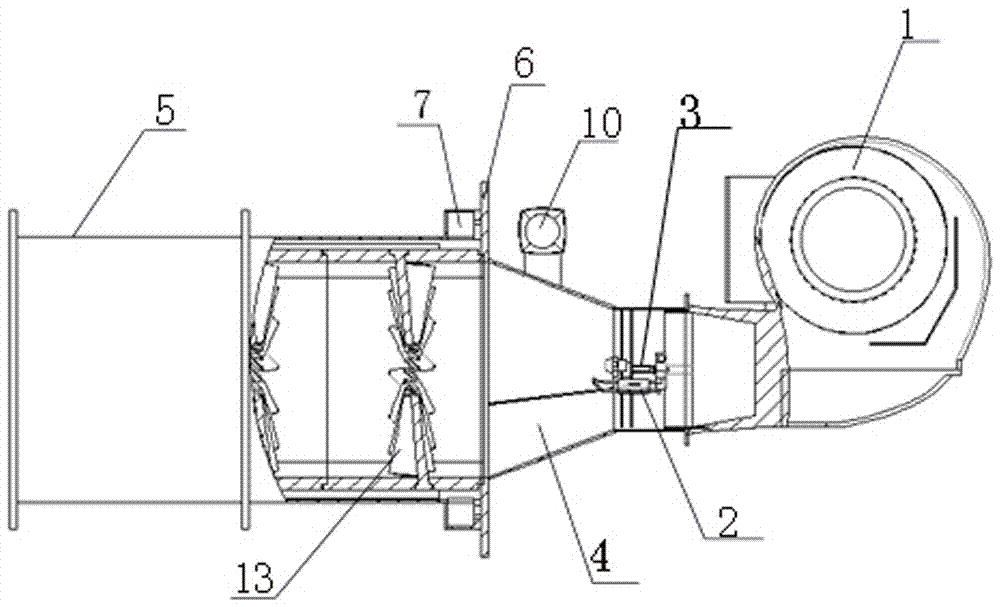

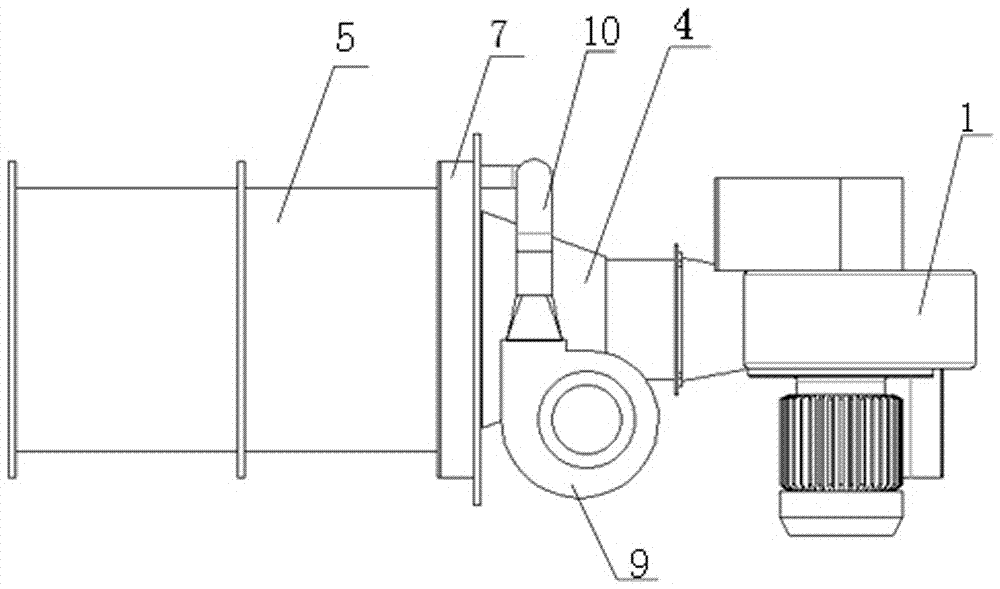

[0028] Turn on the main fan 1, the pressurized methanol is atomized through the nozzle 3 and ignited by the arc of the ignition needle 2, the main fan 1 provides the air and axial wind pressure required for combustion, and the ignited methanol flame is blown into the flame swirler 11, Due to the axial wind pressure of the main fan 1, the ignited flame is forcibly disturbed by the ceramic swirl vanes 13 in the ceramic swirl tube 12, resulting in the superposition of axial and radial velocities to form a rotating flame. Flow to the outlet of the flame cyclone.

[0029] When the nitrogen oxides in the flue gas are high, adjust the air volume of the main fan so that the cyclone is a reducing atmosphere. At this time, a large amount of nitrogen oxides will not be produced. At the outlet of the flame cyclone 11, the secondary fan 9 The generated secondary air is transported to the outlet of the cyclone through the secondary air channel 8, so that the rotating flame and the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com