Pressurized moving bed oxygen thermal method calcium carbide gas integrated production equipment

A technology of production equipment and bed oxygen-thermal method, which is applied in the direction of combustible gas purification, combustible gas purification/transformation, gas dust removal, etc. Improve the efficiency of thermal energy utilization, ensure the quality of calcium carbide products, and improve the environment of the workplace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the features in the implementation manners and examples in the present application can be combined with each other.

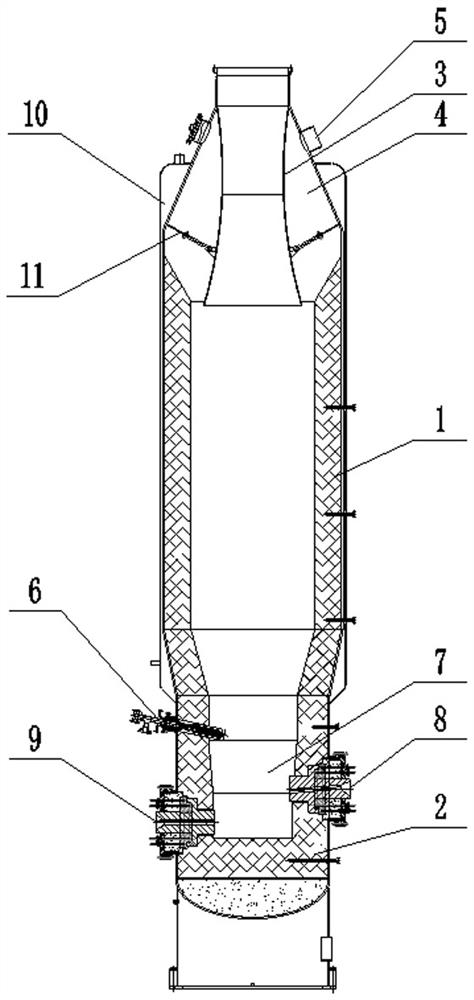

[0033] refer to figure 1 , the pressurized moving bed oxythermal method calcium carbide gas integrated production equipment provided by a typical embodiment of the present invention includes a calcium carbide gasifier, the calcium carbide gasifier includes a furnace body, and the furnace body is a vertical furnace with an inner cavity. Type pressure vessel, above the waist of the furnace body is the first furnace body 1, and below the waist is the second furnace body 2.

[0034] The top of the first furnace body 1 is a frustum structure, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com