Cold accumulating device by ice

An ice cold storage and ice storage technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problem of complex structure of ice-melting ice-storage cylinders, insufficient use of swirling flow enhanced heat transfer technology, and insufficient improvement of melting Ice efficiency and other issues, to avoid excessive operating pressure, improve ice melting efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

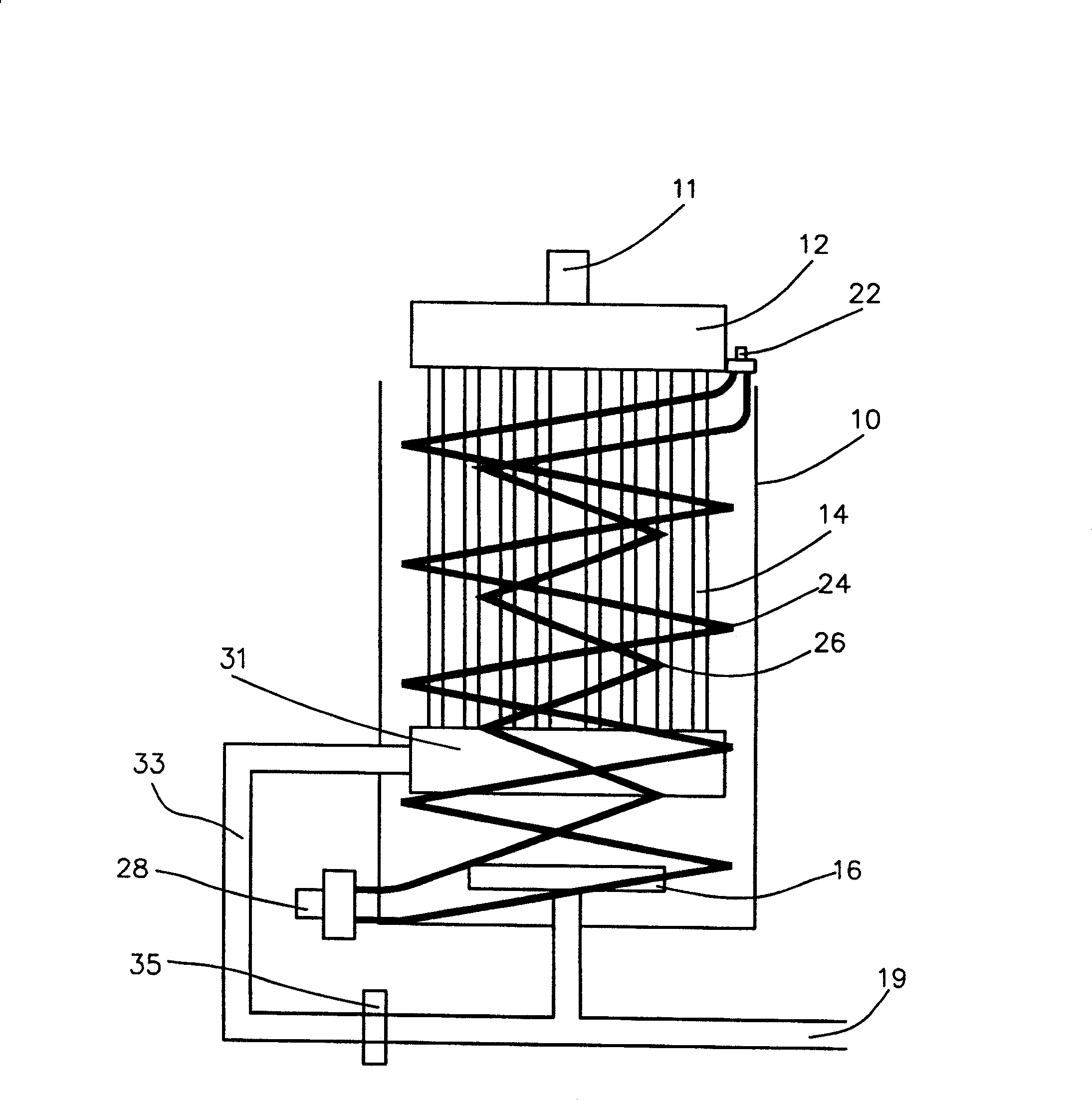

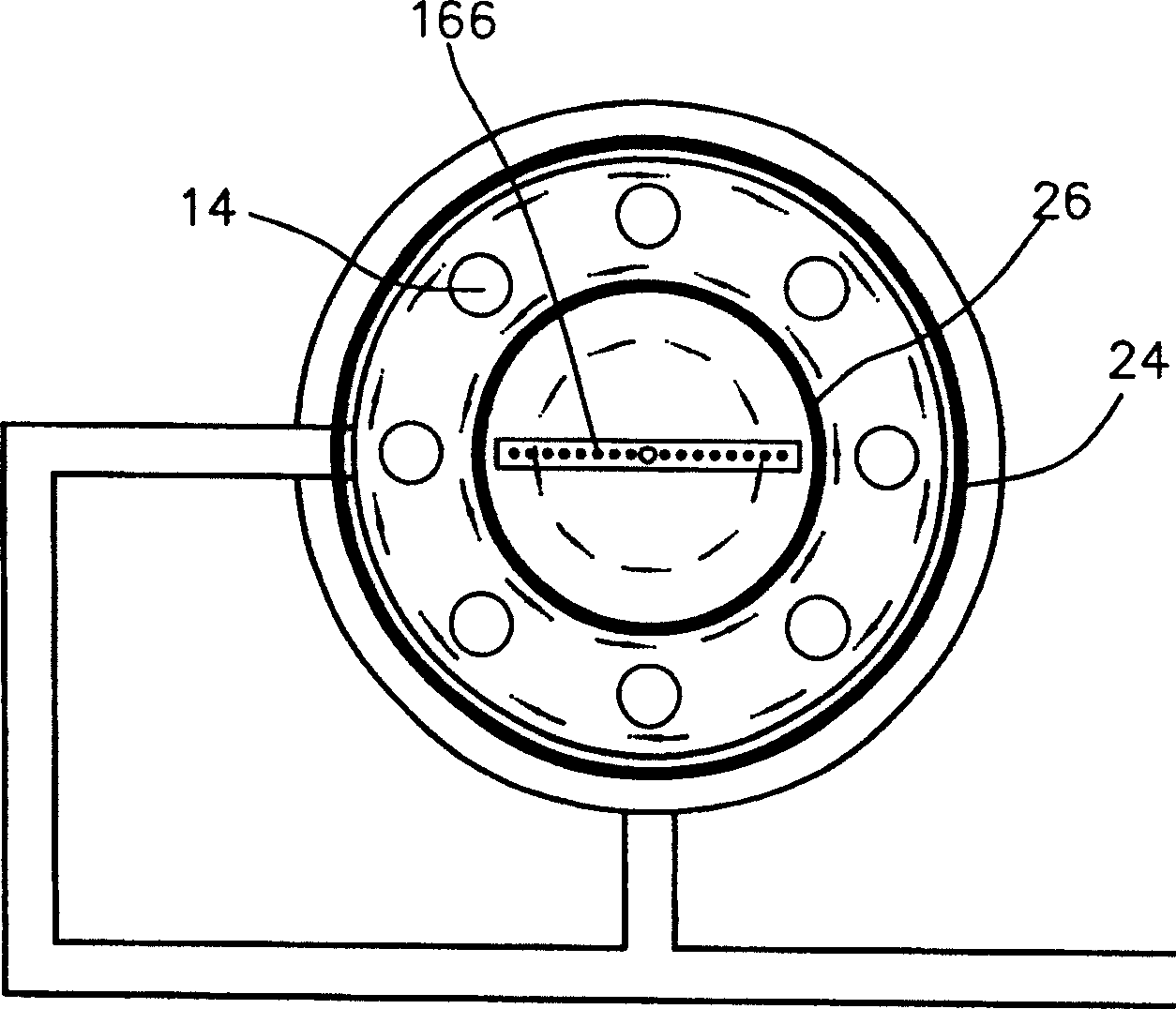

[0040] The ice cold storage device of the present invention is used for ice cold storage of an air-conditioning system to realize off-peak power consumption, and mainly includes an ice melting mechanism, an ice making mechanism, and an ice melting bypass mechanism. Among them, the ice-melting mechanism includes an ice storage cylinder 10, a water inlet 11, an upper header 12, eight ice-melting pipes 14, a water collection pipe 16, and a water supply port 19; the ice-making mechanism includes a coolant inlet 22, two ice-making pipes 24 and 26, and the coolant outlet 28; the ice-melting bypass mechanism includes a lower header 31, a bypass pipe 33, and a solenoid valve 35.

[0041] An ice storage space is formed inside the ice storage cylinder 10, and ice (in this embodiment, ice) that can solidify into a medium under the action of the coolant is injected into the ice storage space of the ice storage cylinder 10 at night when electricity consumption is low. medium (water in this...

Embodiment 2

[0052] As an optional implementation of the present invention, in this embodiment, the ice storage device can be used for ice storage in a freezer or a freezer.

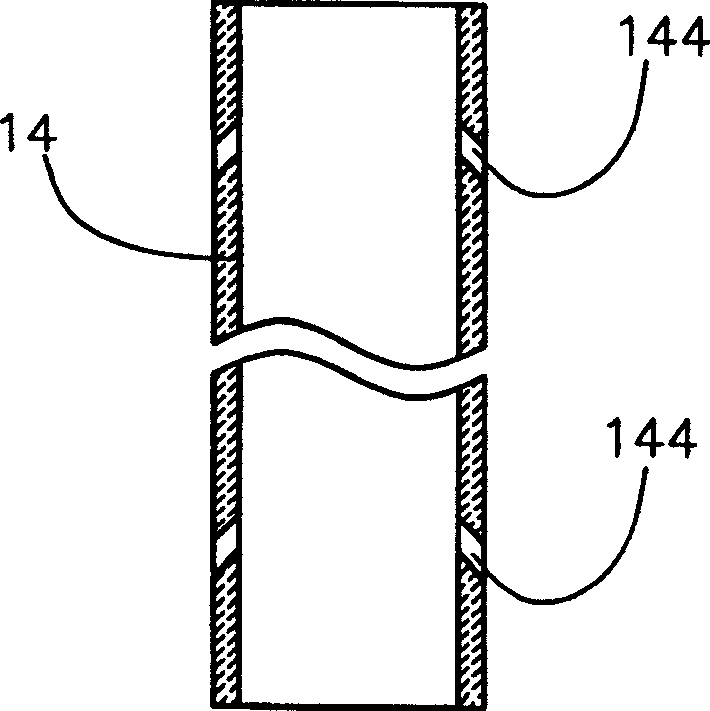

[0053] Alternatively, a row of water injection holes can only be opened on the wall of each ice-melting pipeline 14 facing the axis of the ice storage cylinder 10, and each ice-melting pipeline 14 faces the axis of the ice storage cylinder 10. Between one side of the line and the medium ice (that is, between the inner wall of the virtual cylinder and the ice) both counterclockwise and clockwise vortices can be formed.

[0054] Alternatively, a row of water injection holes 14 may also be provided only on the tube wall on the side away from the axis line of the ice storage cylinder 10, and each ice-melting pipeline 14 is away from the axis line of the ice storage cylinder 10. Between the side and the medium ice (that is, between the outer wall of the virtual cylinder and the ice) both a clockwise vortex and a countercl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com