a low no x Power Plant System and Method Coupling Combustion and White Smoke Reduction

A power station, white smoke technology, applied in combustion methods, combustion equipment, combustion technology mitigation and other directions, can solve the problems of low volatile fuels with high nitrogen oxide emissions, poor ignition and burnout performance, etc., to improve residence time, reduce NOx The amount of production and the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

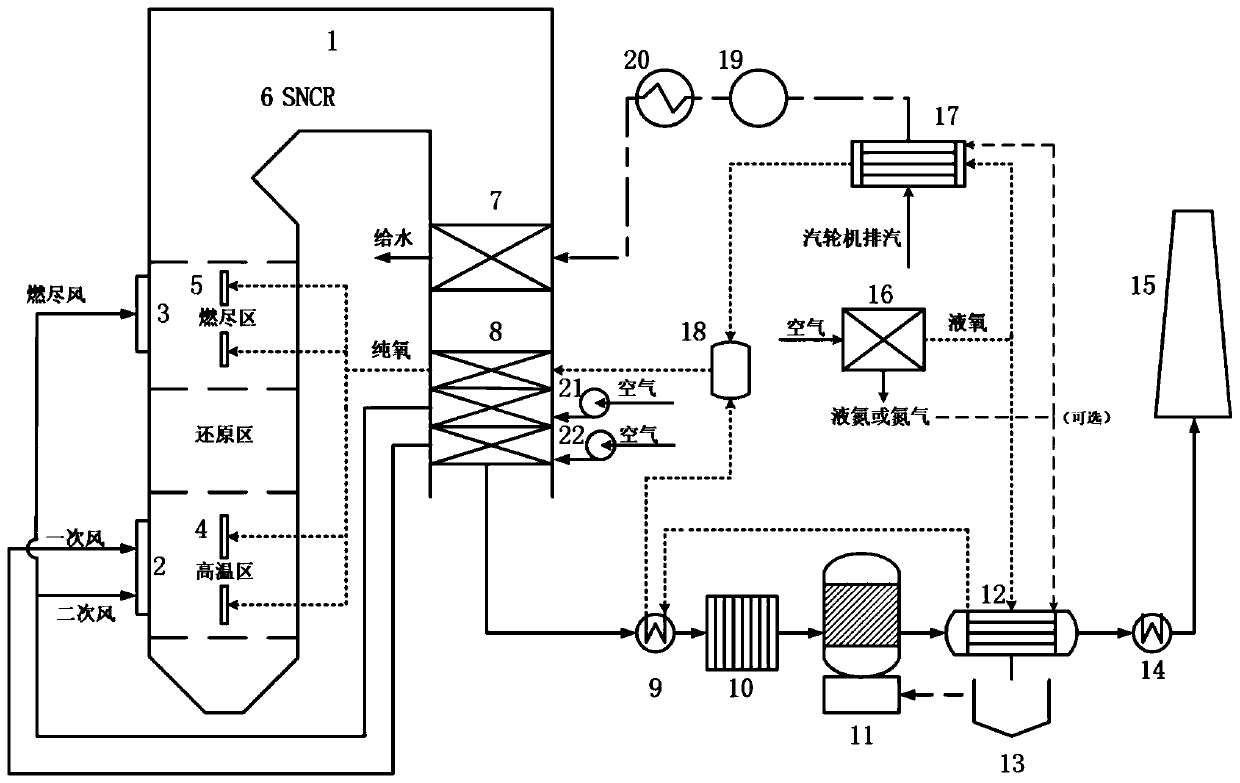

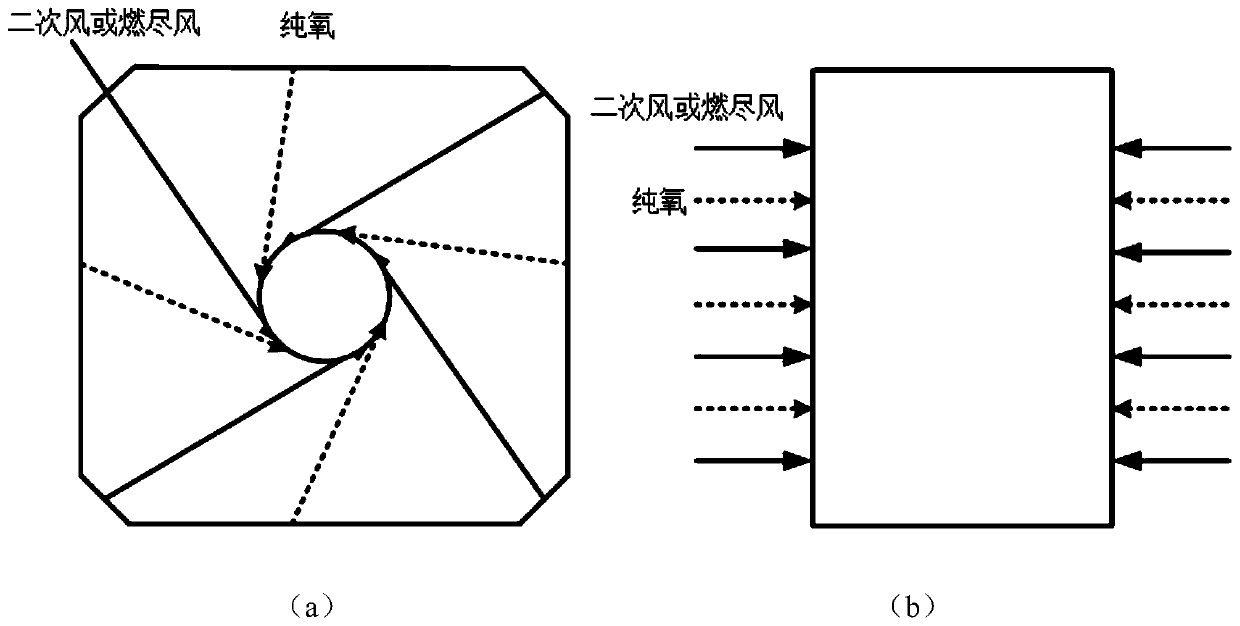

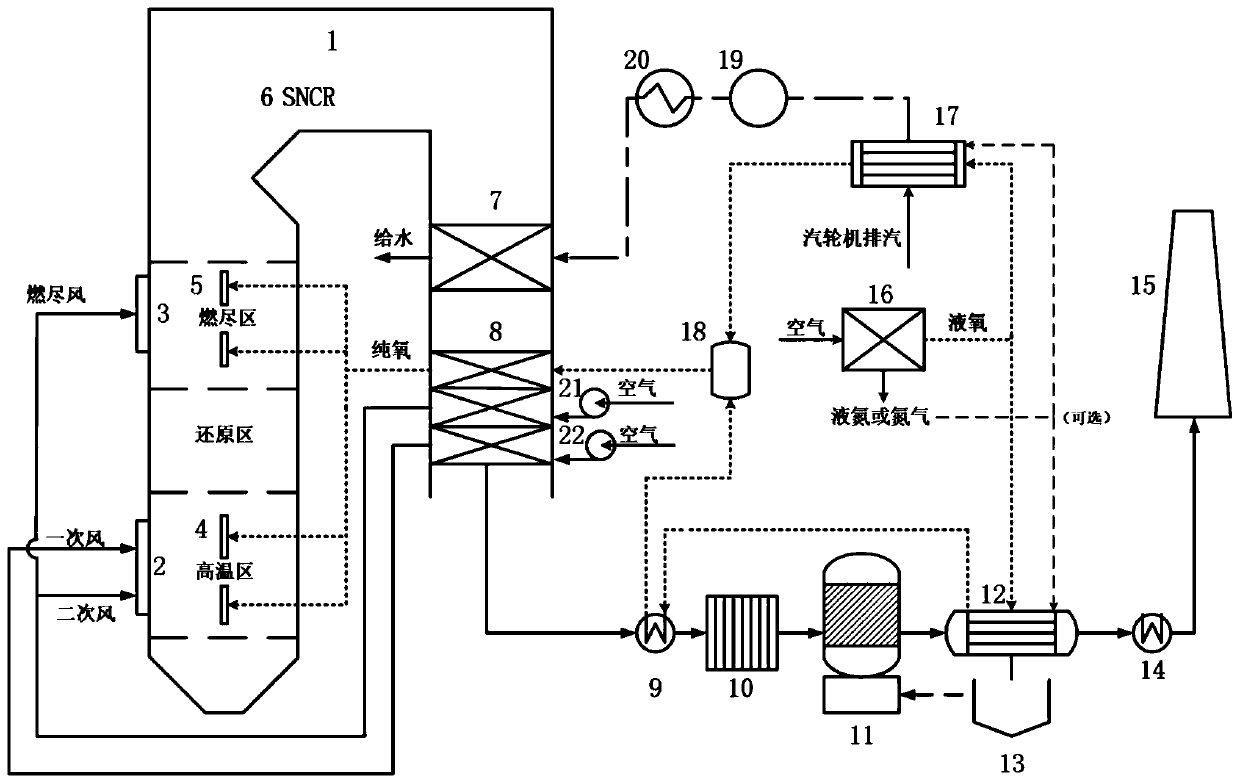

[0038] The purpose of the present invention is to provide a fuel that can realize high-efficiency combustion of low-volatile fuels in power plant boilers, injecting pure oxygen through the wall-type auxiliary air nozzle combined with oxygen depth classification to form a NOx The reduced high-temperature and strong reducing atmosphere solves the problems of high nitrogen oxide emissions and poor ignition and burnout performance of low-volatile fuels, and at the same time makes full use of the cold energy of liquid oxygen obtained by the air separation unit to realize condensed water recycling and eliminate white smoke plumes Integrated power plant boiler with low NO x Combustion system and method, and injecting pure oxygen through the wall wind to form an oxidative atmosphere near the water wall of the furnace to slow down the corrosion of the water wall of the furnace.

[0039] In order to make the purpose, features and advantages of the present invention more obvious and under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com