Photoelectric photo-thermal combined vacuum straight-through heat collector for trench light condensing system

A trough-type concentrating system and photoelectric technology, applied in the field of heat collectors, can solve the problems of absorption, unfavorable heat, large thermal resistance, etc., and achieve the effects of reducing thermal resistance, improving heat exchange efficiency, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

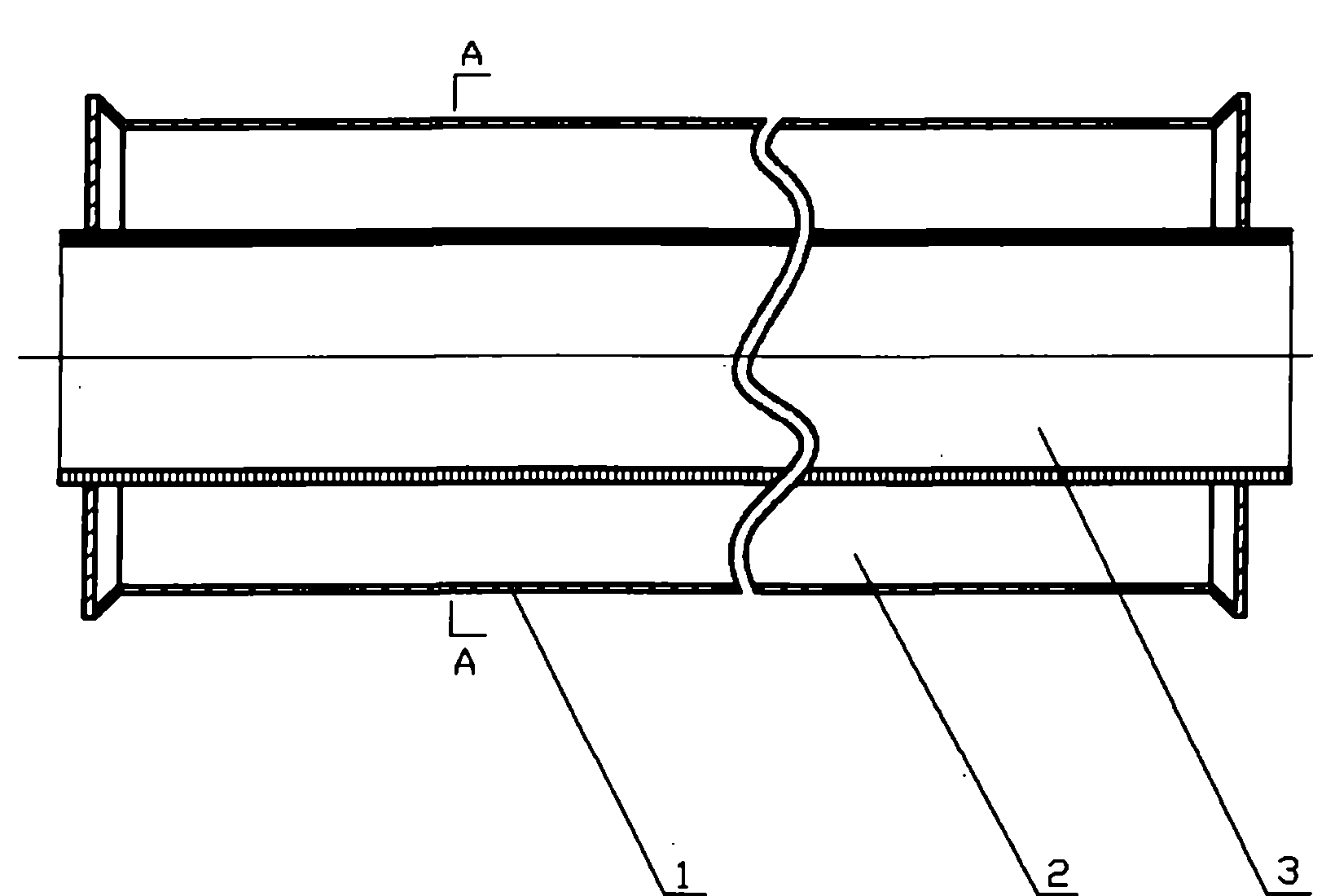

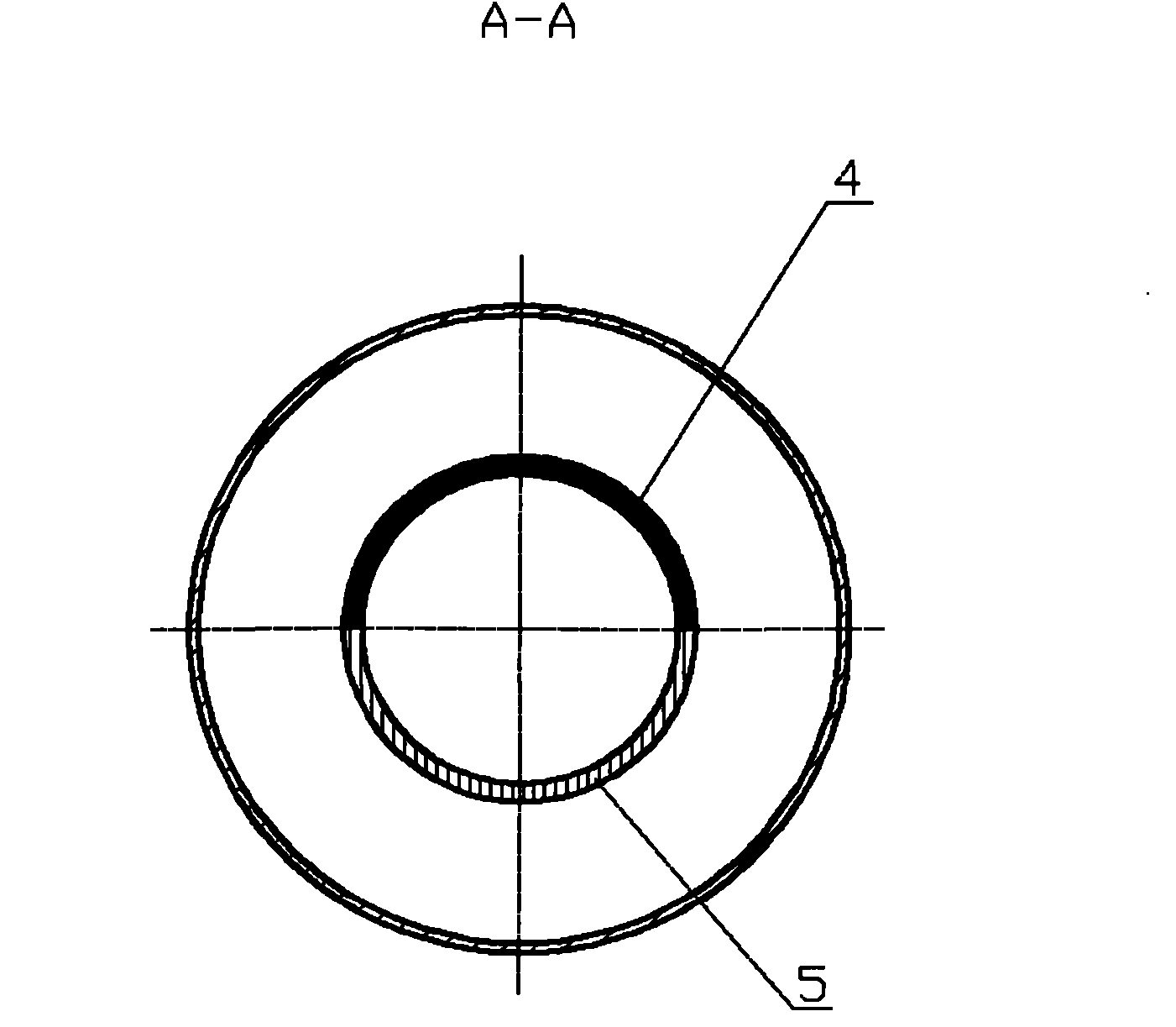

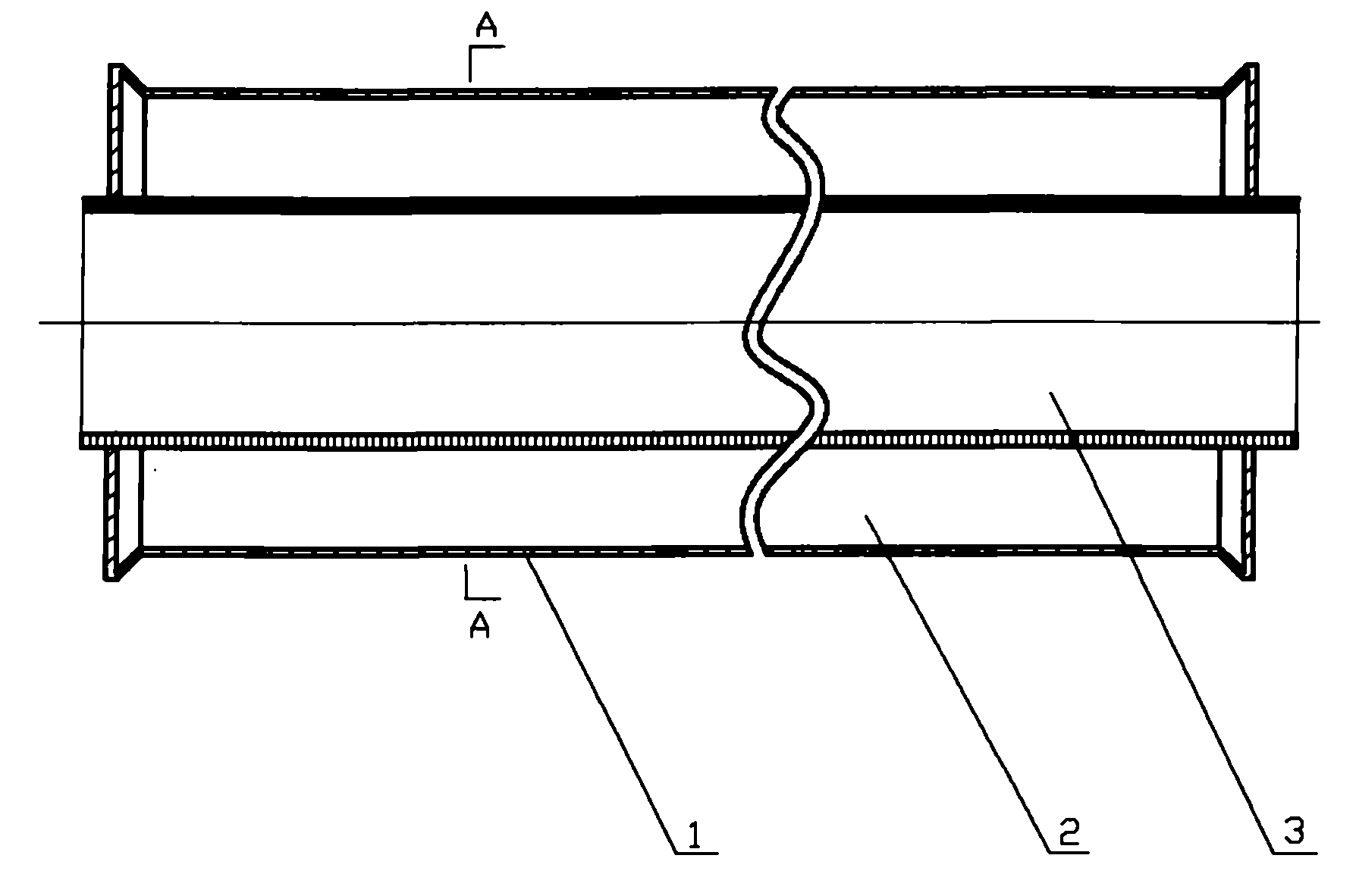

[0015] Such as figure 1 As shown, the present invention is used for the vacuum straight-through heat collecting tube for photoelectricity, light and heat of the trough concentrating system, comprising a vacuum tube 2, the outer tube 1 of the vacuum tube 2 is a glass cover tube, and the inner tube 3 of the vacuum tube 1 is A copper pipe, the diameter of the inner pipe 1 is determined by the actual situation, in the process of use, as long as the water flow is controlled according to the temperature of the circulating water. The two ends of the copper tube and the glass cover tube are sealed by metal sealing technology, and the outer turning surface of the copper tube 3 is divided into a first surface (half of the copper tube circumference) and a second surface with the axially symmetrical plane as the boundary. (the other half of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com